Pepperl+Fuchs

Choose a subcategory:

Show all categories

- Industrial-grade box thin client for 24/7 operation

- Long-term support with product availability for more than 5 years

- Supports modern Ultra HD (4K) setups with 60 Hz

- Compact footprint and wide operating temperature range

(-20 ... 60 В°C) for high installation flexibility

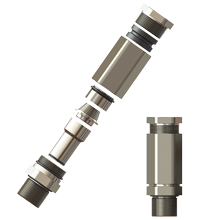

- For armored cables

- Barrier gland

- Stainless Steel

- Thread M75

- Seal silicone

- Ex db, Ex eb and Ex tb certified

- Suitable for operation in Zone 1, Zone 2, Zone 21 and Zone 22

- Packaging unit: 2 pieces, without accessories

- Allows direct connection from a VisuNet Remote Monitor (with RM Shell 4.1 or newer) to a host system

- Supports concurrent remote and local access to an Operator Workstation

Industrial monitors DM515 Series Div 2 Monitor

- Galvanic Isolation I.S. to non-I.S. Port

- 10/100 MBit/s according to IEEE 802.3/.3u

- Installation in Zone 2, Ethernet in Zone 1 or Zone 0

- Standard Ethernet patch or crossover cable

- DIN-Rail mounted and OEM Version

- Galvanic Isolation I.S. to non-I.S. Port

- 10/100 MBit/s according to IEEE 802.3/.3u

- Installation in Zone 2, Ethernet in Zone 1 or Zone 0

- Standard Ethernet patch or crossover cable

- DIN-Rail mounted and OEM Version

- Replaceable SIM

- Global certificates - a common hardware platform

- Android 8.1 operating system

- Wireless connections such as WWAN, 4G LTE, WLAN, etc.

- Android Enterprise Recommended verified device

- GPS

- NFC technology for wireless applications

- Service contract

- Special buttons for push-to-talk (PTT) applications

- Special buttons for lone worker protection (LWP) applications

- Latest available Android version for this device

Segment Protector

- 1-channel

- Fully compatible replacement for FB3203B

- Input Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Power supply for 2- or 3-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- HART communication via field bus or service bus

- HART communication also for separately powered devices

- Simulation mode for service operations (forcing)

- Line fault detection (LFD) and Live Zero monitoring

- Permanently self-monitoring

- 4-channel

- Inputs Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- 4-channel

- Inputs Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD)

- Permanently self-monitoring

- 4-channel

- Outputs Ex ia

- Module can be exchanged under voltage (hot swap)

- Installation in suitable enclosures in Zone 1

- Analog output module for 0/4 mA ... 20 mA

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- 4-channel

- Outputs Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Analog output module for 0/4 mA ... 20 mA

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Output with bus-independent safety shutdown

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via PROFIBUS DP

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via MODBUS TCP

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- HART communication via MODBUS TCP

- Configuration via FDT 1.2 DTM

- Non-volatile memory for configuration and parameter settings

- Self configuration in redundant systems

- Permanently self-monitoring

- Outputs drive to safe state in case of failures

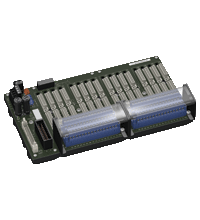

- Standard enclosure for FB-System

- Max. 5 slots for I/O modules

- For FOUNDATION Fieldbus H1

- Impact resistance enclosure, IP66/NEMA 4X

- Packaged certified solution

- Installation in Zone 1

- 8 segments, individual modules per segment

- Supports all PLC and PCS hosts

- High-power trunk: Live work on devices in any hazardous area

- Features for best signal quality, low heat dissipation

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Optional advanced diagnostics

- Passive impedance and CREST technology for high reliability

- Supports Ex ic/nL voltage limitation

- Installation in Zone 2/Div. 2

- 4 segments, redundant, individual modules per segment

- Supports all PLC and PCS hosts

- High-power trunk: Live work on devices in any hazardous area

- Features for best signal quality, low heat dissipation

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Optional advanced diagnostics

- Passive impedance and CREST technology for high reliability

- Supports Ex ic/nL voltage limitation

- Installation in Zone 2/Div. 2

- 8 segments, redundant, individual modules per segment

- Customized for Invensys, FBM228

- High-power trunk: Live work on devices in any hazardous area

- Best quality, smallest size and lowest heat dissipation

- For FOUNDATION Fieldbus H1

- Optional advanced diagnostics

- Passive impedance for high reliability

- Dual, redundant bulk power connections

- System board for Honeywell Safety Manager

- For 16-channel AI card SAI-1620m

- For 16 modules

- Recommended module: HiC2025(A) (AI)

- 24 V DC supply

- Hazardous area: pluggable screw terminals, blue

- Non-hazardous area: SiC plug, 20-pin

- Comprehensive diagnostics for the fieldbus physical layer

- Handheld with display and integrated expert system

- Fieldbus interface Ex ia, FISCO, Entity, and DART

- For commissioning, online monitoring and troubleshooting

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Multi-language support

- Operation in Zone 1/Class I, Div. 1

- Choice of power options for different operating modes

- PC software for enhanced interface and data backup

- Comprehensive diagnostics for fieldbus physical layer and power supply

- Plug-in Module for the FieldConnex Power Hub

- Precise measurements through passive circuits

- For commissioning, online monitoring and troubleshooting

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Display of data in the safety of the control room

- Automatic setup of diagnostic system

- Full software integration into PCS and PAM possible

- Diagnostics for fieldbus physical layer and power supply

- Plug-in Module for the FieldConnex Power Hub

- Plug and play - no engineering required

- For online monitoring

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Alarm limits configurable via DIP switches

- Fault indication transmission by voltage free contact

- Output: 21 ... 23 V/500 mA

- Voltage limitation for Entity ic and Ex nL

- With galvanic isolation

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- High efficiency, low heat dissipation for high packing density

- Hot swappable in redundant configuration

- Module exchange without tools during operation

- Output: 28 ... 30 V/500 mA

- High-power trunk for high device count and long cable lengths

- With galvanic isolation

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- High efficiency, low heat dissipation for high packing density

- Hot swappable in redundant configuration

- Module exchange without tools during operation

- PROFIBUS DP V1 / For 4 segments PA

- Couples PROFIBUS PA devices transparently to PROFIBUS DP

- Optional redundant configuration

- Installation in Zone 2/Class I, Div. 2

- Up to 12 Mbit/s, auto adapting

- For redundant and non-redundant masters

- Supports Flying Redundancy (FR)

- Cyclic/acyclic data exchange

- Gateway PROFINET RT to 4 x PROFIBUS PA segments

- Up to 32 devices per PROFIBUS PA segment

- Installation in Zone 2/Class I, Div. 2

- Ring and system redundancy

- Integrated webserver for diagnostics

- 1-channel isolated barrier

- 24 V DC supply (bus powered)

- Input for 2-wire SMART transmitters and current sources

- Signal splitter (1 input and 2 outputs)

- Dual output 0/4 mA ... 20 mA or 0/1 V ... 5 V

- Up to SIL 2 acc. to IEC 61508

- 1-channel isolated barrier

- 24 V DC supply (bus powered)

- Input for 2-wire SMART transmitters and current sources

- Signal splitter (1 input and 2 outputs)

- Dual output 0/4 mA ... 20 mA or 0/1 V ... 5 V

- Up to SIL 3 acc. to IEC 61508