Pepperl+Fuchs

Choose a subcategory:

Show all categories

- 2-channel signal conditioner

- 24 V DC supply (Power Rail)

- Thermocouple, RTD, potentiometer or voltage input

- Usable as signal splitter (1 input and 2 outputs)

- Voltage output 0/1 V ... 5 V

- Configurable by PACTware

- Line fault (LFD) and sensor burnout detection

- Up to SIL 2 acc. to IEC 61508/IEC 61511

1-channel isolated barrier

24 V DC supply (Power Rail)

Thermocouple, RTD, potentiometer or voltage input

1-channel isolated barrier

24 V DC supply (Power Rail)

1-channel isolated barrier

24 V DC supply (Power Rail)

Voltage input 0 V ... -20 V

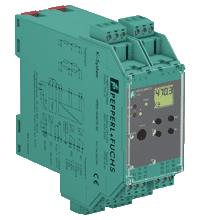

- 1-channel signal conditioner

- 24 V DC supply (Power Rail)

- Strain gauge input (full or half bridge)

- Output 0 mA ... В± 20 mA or 0 V ... В± 10 V

- 2 relay contact outputs

- Programmable high/low alarm

- Configurable by PACTware or keypad

- RS-485 interface

- Line fault detection (LFD)

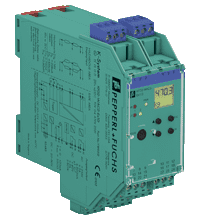

- 1-channel isolated barrier

- 24 V DC supply (Power Rail)

- Strain gauge input (full or half bridge)

- Output 0 mA ... В± 20 mA or 0 V ... В± 10 V

- 2 relay contact outputs

- Programmable high/low alarm

- Configurable by PACTware or keypad

- RS-485 interface

- Low response time

- Line fault detection (LFD)

- 1-channel signal conditioner

- Universal usage at different power supplies

- Thermocouple, RTD, potentiometer or voltage input

- Redundant TC input

- Current output 0/4 mA ... 20 mA

- 2 relay contact outputs

- Configurable by PACTware or keypad

- Line fault (LFD) and sensor burnout detection

- Up to SIL 2 acc. to IEC 61508/IEC 61511

- 1-channel signal conditioner

- Universal usage at different power supplies

- Input for 2- or 3-wire sensors, NAMUR sensors or dry contacts

- Input frequency 1 mHz ... 10 kHz

- Current output 0/4 mA ... 20 mA

- Relay contact and transistor output

- Start-up override

- Line fault detection (LFD)

- Up to SIL 2 acc. to IEC 61508/IEC 61511

- 1-channel signal conditioner

- Universal usage at different power supplies

- Input for 2- or 3-wire sensors, NAMUR sensors or dry contacts

- Input frequency 1 mHz ... 10 kHz

- Current output 0/4 mA ... 20 mA

- Relay contact and transistor output

- Start-up override

- Line fault detection (LFD)

- Up to SIL 2 acc. to IEC 61508/IEC 61511

- 2-channel signal conditioner

- Universal usage at different power supplies

- Dry contact or NAMUR inputs

- Input frequency 1 mHz ... 1 kHz

- Current output 0/4 mA ... 20 mA

- Relay contact and transistor output

- Start-up override

- Configurable by PACTware or keypad

- Line fault detection (LFD)

- Output: 25 ... 27 V/360 mA

- For most fieldbus applications

- High-power trunk for high device count and long cable lengths

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1

- Fixed, high-availability terminator

- No spacing required between modules

- Output: 24 ... 26 V/400 mA

- For extension of fieldbus segments

- High-power trunk for high device count and long cable lengths

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Fixed, high-availability terminator

- High efficiency, low heat dissipation

- Supply via Power Rail

- Power supply of fieldbus segments according to IEC 61158-2

- Signal repeater for fieldbus topologies in accordance to Entity

- 70 mA supply of the field side

- Improves the fieldbus signal

- Extension of the transmission distance by means of opening a new fieldbus segment

- Integrated bus terminations

- Removable terminals and Power Rail connection for simple installation

- Supply via Power Rail

- Power supply of fieldbus segments according to IEC 61158-2

- Signal repeater for fieldbus topologies in accordance to FISCO

- 100 mA supply of the field side

- Improves the fieldbus signal

- Extension of the transmission distance by means of opening a new fieldbus segment

- Integrated bus terminations

- Removable terminals and Power Rail connection for simple installation

- Supply via Power Rail

Plastic fiber optic

- Comprehensive diagnostics for the fieldbus physical layer

- Module and motherboard for retrofit of any installation

- Precise measurements through passive circuits

- For commissioning, online monitoring and troubleshooting

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Display of data in the safety of the control room

- Full software integration into PCS and PAM possible

- System integration kit for Advanced Diagnostics

- PCS integration via Diagnostic Manager or device DTM

- Simple automatic setup of Advanced Diagnostics

- Common alarm handling

- For FOUNDATION Fieldbus and PROFIBUS PA

- Installation in Zone 2

- System integration kit for Advanced Diagnostics

- PCS integration via Diagnostic Manager or device DTM

- Simple automatic setup of Advanced Diagnostics

- Alarm handling and integrated I/O for cabinet monitoring/control

- For FOUNDATION Fieldbus and PROFIBUS PA

- Installation in Zone 2

Complete hardware for connection of FOUNDATION Fieldbus H1 field devices to the host system of your choice

Complete hardware for connection of PROFIBUS PA field devices to a DP-Master

- 4-channel

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Installation in Zone 2 or safe area

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Module can be exchanged under voltage

- 4-channel

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Installation in Zone 2 or safe area

- Supply circuit 21.5 V (4 mA)

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Module can be exchanged under voltage

- 4-channel

- Inputs Ex ia

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Module can be exchanged under voltage

- 4-channel

- Inputs Ex ia

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Module can be exchanged under voltage

- 8-channel

- Outputs Ex ib

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- Module can be exchanged under voltage

- Galvanic group isolation

- Line fault detection (LFD)

- Positive or negative logic selectable

- Simulation mode for service operations (forcing)

- Permanently self-monitoring

- Output with watchdog

- Output with bus-independent safety shutdown

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via MODBUS RTU

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- HART communication via service bus

- Configuration via FDT 1.2 DTM

- Non-volatile memory for configuration and parameter settings

- Self configuration in redundant systems

- Permanently self-monitoring

- Outputs drive to safe state in case of failures

- Module can be exchanged under voltage

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via PROFIBUS DP

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- HART communication via PROFIBUS DP V1 or service bus

- Configuration via FDT 1.2 DTM

- Configuration in run (CiR) for any PCS

- Non-volatile memory for configuration and parameter settings

- Self configuration in redundant systems

- Permanently self-monitoring

- Outputs drive to safe state in case of failures

- Module can be exchanged under voltage

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via PROFIBUS DP

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- HART communication via PROFIBUS DP V1 or service bus

- Configuration via FDT 1.2 DTM

- Configuration in run (CiR) for any PCS

- Non-volatile memory for configuration and parameter settings

- Self configuration in redundant systems

- Permanently self-monitoring

- Outputs drive to safe state in case of failures

- Module can be exchanged under voltage

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via MODBUS TCP

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- HART communication via MODBUS TCP or service bus

- Configuration via FDT 1.2 DTM

- Non-volatile memory for configuration and parameter settings

- Self configuration in redundant systems

- Permanently self-monitoring

- Outputs drive to safe state in case of failures

- Module can be exchanged under voltage

- Interface between the I/O modules and the PCS/PLC

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- Non-volatile memory for configuration and parameter settings

- Communication via PROFINET

- HART communication via PROFINET and HART I/P