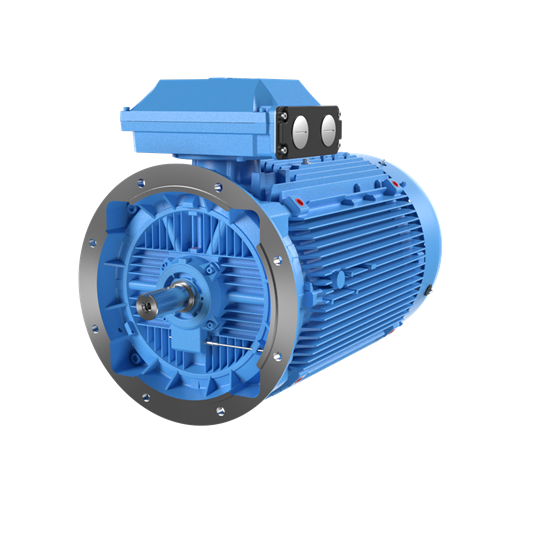

ABB M3BP 3GBP

3-Phase squirrel cage motor. M3BP 112MB 4

Cast Iron Motor. Output power 15kW, enclosure protection IP55.

IE2 High Efficiency Cast Iron Motors, 22 kW, 400 V

3-Phase squirrel cage motor

ABB low voltage Cast Iron Motor with high level of efficieny. 4 poles, output power 55 kW and input voltage 400-460 V.

M3BP 250 SMA 4,TEFC, 3-phase, squirrel cage induction motor

IE2 High Efficiency Cast Iron Motors, 90 kW, 400 V

IE2 High Efficiency Cast Iron Motors, 75 kW, 400 V

M3BP 315 SMC 4 Motor

3-Phase squirrel cage motor

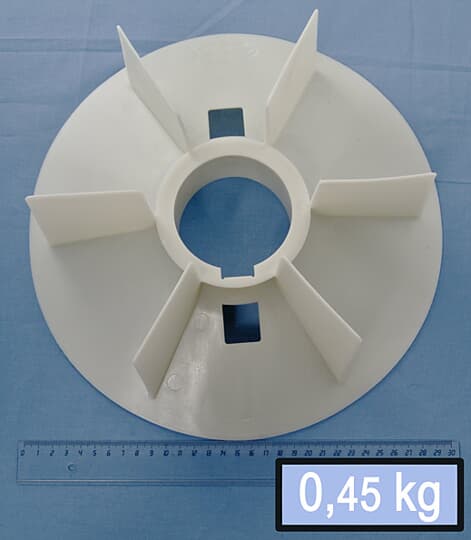

FAN M3BP/GP/HP 280SM,315SM,ML

Electric motor ABB M3BP 132 SMB4 5.5 kW 1500 r / min

- 1623888704

- Vendor Number: 3GBP312230-BXGAC02

- Vendor Number: 3GBP312410-ADG

- Product Identification Number: 3GBP311220-ADK

- Product Number: 3GBP353810-ADG

M3BP 160MLA 4

M3BP 160MLC 2

Low voltage ABB AC Cast Iron Motors. High efficiency class IE2.

3-Phase squirrel cage motor

Low voltage process performance cast iron motor with high efficiency level and cast iron material.

- Vendor Identification Number: 3GBP102510-ASL

- Item Identification Number: PTNBP102510-ASL

- Product Identification Number: 3GBP101322-BSB

- Vendor Identification Number: 3GBP102323-AEB

- Vendor Code: 3GBP102445-CHB

- Vendor Number: 3GBP101810-BCK

- Item Number: 3GBP102810-BCK

- Product Code: 3GBP102820-BCK

M3BP motors are part of ABB's extensive portfolio of industrial motors, designed to meet the stringent requirements of various applications across multiple industries. These motors are known for their reliability, efficiency, and versatility. Today, we will take a closer look at this type of ABB motor.

ABB M3BP Motors: Engineered for Peak Performance

ABB M3BP motors are engineered to deliver peak performance across various industrial applications. Here's how these motors achieve and maintain their high-performance standards.

Rugged construction

ABB M3BP motors are built to withstand the rigors of industrial environments. They are engineered for durability, reliability, and long service life with robust construction and high-quality materials, even in harsh operating conditions. ABB M3BP mounting options allow you to place motors in the most suitable places.

High-efficiency operation

ABB M3BP motors are designed to meet or exceed international efficiency standards such as IE3 or higher. By reducing energy losses during operation, these motors help industrial facilities minimize energy consumption and lower operating costs while maintaining superior performance.

Optimized design

ABB invests heavily in research and development to design M3BP motors with optimized geometries and materials. These motors are meticulously engineered to minimize losses, maximize efficiency, and ensure robust performance under various operating conditions.

Precision control

M3BP motors are compatible with ABB's advanced motor control technologies, including variable frequency drives (VFDs) and sophisticated control algorithms. This allows for precise speed and torque control, enabling optimal performance and energy efficiency across various operating conditions.

Comprehensive testing

Before leaving the factory, each M3BP motor undergoes rigorous testing and quality assurance procedures to ensure compliance with performance standards and specifications. This meticulous testing process guarantees that every motor meets ABB's high-quality standards and delivers consistent, reliable performance in the field.

Advanced cooling systems

M3BP motors feature advanced cooling systems that efficiently dissipate heat generated during operation to prevent overheating and ensure reliable operation. This ensures stable motor performance even in high-temperature environments or under heavy loads.

Application-specific solutions

ABB offers various customization options for M3BP motors to meet specific application requirements. Whether adjusting motor size, voltage and frequency ratings, mounting options, or other parameters, ABB can tailor M3BP motors to suit the unique needs of different industrial applications.

ABB M3BP Specifications: Power, Efficiency, & Versatility

The ABB M3BP motors come in various specifications, offering power, efficiency, and versatility to suit diverse industrial applications. Here are the key specifications of ABB M3BP motors:

- Power range. ABB M3BP motors cover a wide power range, from fractional horsepower (kW) to several megawatts. This ensures a motor is available for applications of varying sizes and power requirements.

- Voltage and frequency. These motors are designed to operate on different voltage and frequency ratings to accommodate various power supply systems and application needs. Standard voltage ratings include 230V, 400V, 460V, and 690V, with frequencies typically ranging from 50Hz to 60Hz.

- Efficiency. ABB motors are engineered for high efficiency to meet or exceed international efficiency standards such as IE3 or higher. This helps industrial facilities reduce energy consumption and operating costs while maintaining superior performance.

- Enclosure. M3BP motors are available in various enclosure types, including open drip-proof (ODP), totally enclosed fan-cooled (TEFC), and explosion-proof enclosures. This ensures suitability for different environmental conditions and safety requirements.

- Construction. The construction of M3BP motors typically involves high-quality materials such as cast iron or aluminum for the frame, ensuring durability and reliability in industrial environments.

- Insulation class. These motors are often designed with different insulation classes (e.g., Class F or Class H) to withstand high temperatures and ensure reliable operation over the motor's lifespan.

- Protection. These motors have built-in thermal protection devices, such as thermostats or thermistors, to safeguard against overheating and prevent motor damage.

- Customization. ABB offers customization options for M3BP motors to meet specific application requirements. This may include variations in motor size, shaft configurations, cooling methods, and other parameters to ensure optimal performance in various industrial settings.

- Certifications. ABB M3BP motors comply with relevant industry standards and regulations, carrying certifications from CE, UL, CSA, and others, ensuring safety, reliability, and environmental sustainability.

Industrial Applications of ABB M3BP Motors

Each ABB M3BP motor is extensively used across various industrial applications due to its versatility, reliability, and high performance. Here are some typical industrial applications where these motors are employed:

- Pumps. Motors power pumps are used in water and wastewater treatment, oil and gas, chemical processing, and mining. These motors drive centrifugal, diaphragm, submersible, and other pumps essential for fluid transfer and processing.

- Fans and blowers. M3BP motors drive fans and blowers in HVAC systems, industrial ventilation, and cooling applications. These motors are also used in air handling units, exhaust fans, cooling towers, and other equipment to maintain optimal air quality and temperature in industrial facilities and commercial buildings.

- Compressors. Commonly used to drive compressors in manufacturing, food and beverage, pharmaceuticals, and refrigeration industries. These motors power reciprocating compressors, rotary screw compressors, and centrifugal compressors for generating compressed air, gases, and refrigerants.

- Conveyors. M3BP drive conveyor systems in manufacturing, distribution, and material handling applications. These motors power belt conveyors, roller conveyors, and other conveyor systems are used for transporting bulk materials, packages, and products throughout industrial facilities and warehouses.

- Mixers and agitators: In the chemical, pharmaceutical, food and beverage, and cosmetics industries, ABB M3BP motors drive mixers and agitators used for blending, mixing, and homogenizing liquids, powders, and slurries in various manufacturing processes.

- Crushers and grinders. Motors power crushers, grinders, and shredders in the mining, aggregates, and recycling industries. These motors drive equipment used for size reduction, material processing, and waste management.

- Machine tools. Motors drive machine tools such as lathes, mills, drills, and grinders in metalworking, woodworking, and other machining industries. These motors provide the high torque and precise control required for machining operations.

- Hoists and cranes. M3BP motors drive hoists, winches, and crane systems in manufacturing, construction, and logistics applications — these motors powerlifting and material handling equipment for moving heavy loads safely and efficiently.

ABB M3BP: Installation and Maintenance Considerations

When installing and maintaining every device from the ABB M3BP catalogue, several vital considerations ensure optimal performance, reliability, and safety:

- Ensure the motor is installed correctly according to ABB's installation guidelines and local electrical codes. This includes proper mounting, alignment, and connection of electrical wiring. Improper installation can lead to premature motor failure or safety hazards.

- When installing the motor, consider the operating environment. Ensure adequate ventilation, protection from moisture, dust, and corrosive substances, and compliance with specified temperature and altitude limits. Proper environmental conditions prolong motor life and prevent damage.

- Verify the motor is connected to the correct voltage and frequency power supply specified on the motor nameplate. Operating the motor outside of its rated voltage and frequency range can damage it and compromise its performance.

- Establish a maintenance schedule for the motor based on ABB's recommendations and industry best practices. This includes periodic inspections, lubrication of bearings (if applicable), cleaning, and testing of electrical connections. Regular maintenance prolongs motor life and prevents unexpected failures.

- Insulation resistance testing should be performed regularly to detect degradation or moisture ingress. It should meet ABB's specified values to ensure electrical safety and prevent motor damage.

- Monitor motor vibration levels during operation to detect potential issues such as misalignment, bearing wear, or rotor imbalance. Excessive vibration can lead to premature failure and should be addressed promptly.

- Monitor motor temperature using built-in or external sensors to prevent overheating. High temperatures can indicate overload conditions, insufficient ventilation, or other issues requiring attention.

Sourcing Your ABB M3BP Motor: Pricing and Availability

If you are looking for the equipment necessary for your applications, you can contact Eltra Trade. If you want to learn more about ABB motors, then on our website you can always find the ABB M3BP motor manual. Moreover, if you need advice, our managers are always ready to answer any of your questions and provide detailed ABB M3BP technical data.