Bosch Rexroth Linear motion

MINIATURE GUIDE RAIL RESIST NRII MSA-012-SNS-H-MA-00

KU-B8-OFK

Ball transfer units without felt seal – Size 15

KU-B15-OFK

KU-B22-MFG

KU-B30-MFG

KUF-B45-TF-MFG

Ball transfer units without felt seal – Size 12

KUM-A12-OFK

KUS-B22-MFG

KUK-B15-MFG

KBM-25-D

KBM-12-DD

KBM-16-DD

KBM-20-DD

KBM-25-DD

KBM-30-DD

KBM-40-DD

KBM-50-DD

KBM-80-DD

KBM-5-DD

KBM-8-DD

KBM-E-20-DD

KBM-O-16-DD

KBM-O-25-DD

KBC-16

KBC-12-DD

KBC-16-DD

KBC-20-DD

Bosch Rexroth is a leading name in industrial automation and engineering, known for its innovative solutions in linear motion technology.

The term "Bosch Rexroth Linear Motion" describes an extensive line of parts and systems intended to enable accurate linear movement in a variety of industrial settings. The controlled, precise, and effective linear motion that these technologies provide is fundamental to industrial automation and can be used to a wide range of industries, such as manufacturing, robotics, packaging, and material handling.

Core Components of Bosch Rexroth Linear Motion

Many essential components of Bosch Rexroth's linear motion technology come together to create a dependable and seamless linear movement:

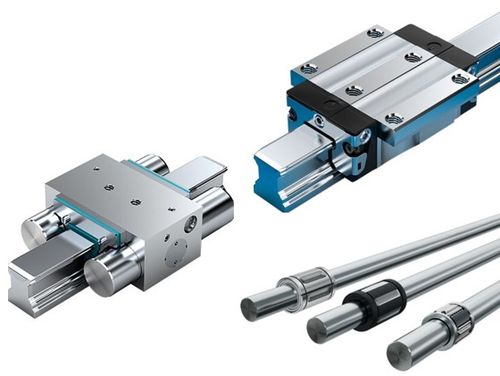

- Linear Guides: These guides consist of a track system that allows carriages to move along a linear path. They ensure stability and smooth movement, providing the backbone for many linear motion applications.

- Linear Bearings: Bearings reduce friction within linear motion systems, allowing for smoother operation and longer-lasting performance. Bosch Rexroth's linear bearings are designed for high load capacity and durability.

- Linear Actuators: Actuators are the driving force behind linear motion, converting energy into movement. Bosch Rexroth offers various types, including electric and pneumatic actuators, providing flexibility for different industrial needs.

- Ball Screws: By transforming rotational motion into linear motion, ball screws allow precise control and positioning. Ball screws from Bosch Rexroth are renowned for their remarkable efficiency and accuracy.

How Bosch Rexroth Linear Motion Works

These elements work together in Bosch Rexroth Linear Motion systems to produce linear movement that is accurate, regulated, and smooth:

- Guided Movement: Linear guides, consisting of rails and carriages, create a defined path for movement. These guides are engineered to minimize friction and maintain accuracy over long distances and heavy loads.

- Actuation and Control: Carriages are propelled along the guides using linear actuators. Different kinds of feedback methods can be used to regulate actuators, assuring accurate movement and halting at precise locations.

- Conversion of Motion: Ball screws have a large load capacity and can precisely place objects by converting rotational motion into linear motion. For situations where precision and quickness are critical, this conversion procedure is vital.

- Load Management: Linear bearings and other support components help manage loads and reduce friction, ensuring smooth operation and extending the lifespan of the system.

Types of Bosch Rexroth linear actuators and their advantages

Bosch Rexroth offers a variety of solutions for linear motion, each with its own unique advantages

Ball transfer units

- Compactness and versatility: These small blocks provide freedom of movement in all directions (linear, rotational) and are suitable for moving, turning, and directing loads.

- Economical and low maintenance requirements: Simple design and self-lubricating elements make them a cost-effective solution with minimal maintenance requirements.

- Limitations: They are not intended for high loads, contaminated environments or applications with shock loads.

Linear guides

- Precision and smoothness of movement: Provide extremely precise and silent slide of the carriage along the rail, which is critical for applications with high positioning accuracy.

- Rigidity and durability: crafted from premium materials, they are able to withstand high loads and ensure long-term operation.

- Versatility: There are different options in terms of size, load capacity and speed, which allows you to choose them for specific needs.

- Applications: Ideal for CNC machines, robotics, laser cutting, etc.

Screw drives

- High accuracy and repeatability: Outstanding positioning performance is achieved by precisely translating the motor's rotating action into linear motion.

- Load Capacity: Screw drives are capable of handling heavy loads efficiently, making them suitable for power applications.

- Versatility: Slotted or ball screw options allow you to optimize speed and load.

- Application: Used in machines, medical equipment, printing presses, etc.

Choosing the right type of Bosch Rexroth linear actuator depends on your specific needs.

Industries Using Linear Motion from Bosch Rexroth

Serving numerous sectors, Bosch Rexroth Linear Motion is an essential part of industrial automation. It is the best choice for a variety of applications, from high-tech robotics to manufacturing, because to its precision, dependability, and versatility.

Manufacturing and Production

Bosch Rexroth Linear Motion is utilized in production and manufacturing for a variety of tasks, including as machine tools, assembly lines, and material handling. Linear motion systems are a valuable tool for improving efficiency and quality by automating repetitive processes, speeding up production, and maintaining high precision. These systems are used by manufacturers for tasks like drilling, cutting, welding, and assembly.

Automotive Industry

At many phases of the vehicle production process, the automotive sector uses Linear Motion systems. Automated assembly procedures, such as component installation, painting, and welding, are made possible by linear actuators and guides, which guarantee precision. These systems are robustly designed to resist the demanding workloads and harsh environments seen in car production operations.

Robotics and Automation

The technology of linear motion is essential to automation and robotics. Automated guided vehicles (AGVs), robotic arms, and gantry systems all require linear motion components made by Bosch Rexroth. These technologies provide the accuracy and adaptability needed to automate difficult jobs like welding, palletizing, and pick-and-place processes. Robots with linear motion can function precisely and smoothly, which makes industrial environments highly automated.

Packaging and Logistics

Automating procedures like filling, sealing, labeling, and sorting requires the use of Bosch Rexroth Linear Motion in the packaging and logistics sectors. Enhancing throughput and efficiency, linear motion systems facilitate precise and swift packaging operations. With the automation of material handling operations, logistics may increase production and decrease the demand for physical labor.

Food and Beverage Industry

Rexroth linear motion is used in automated production lines and processing equipment, which aids the food and beverage industry. In the processing and packaging of food, linear motion systems play a crucial role in upholding strict, hygienic, and precise standards. They are easy to clean and resistant to corrosive situations, and they are made to comply with industrial norms.

Aerospace and Defense

In aerospace and defense, Bosch Rexroth Linear Motion is used for its reliability and precision. Applications include aircraft assembly, missile production, and maintenance equipment. The ability to handle heavy loads and operate in challenging conditions makes these systems valuable in aerospace manufacturing and defense projects.

Electronics and Semiconductor Manufacturing

Another application for Bosch Rexroth Linear Motion is in the electronics and semiconductor sectors, where accuracy is essential. These systems provide accurate placement and movement in processes including wafer handling, component placement, and PCB (Printed Circuit Board) assembly. Outstanding repeatability and accuracy are critical for linear motion systems in these high-tech industries.

With its precision, dependability, and flexibility in automation processes, Bosch Rexroth Linear Motion is essential to many different sectors. These excellent items are offered in a comprehensive catalog by Eltra Trade, which serves a variety of industrial applications. Eltra Trade's experienced managers are always available to help, making sure you get the ideal solution for your application if you have any queries regarding certain features or product selection.