IFM IO-Link Software

App AC14 O3D300

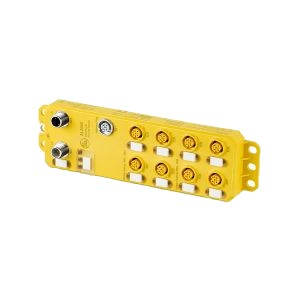

ifm io-link safety

- Power supply voltage: 10 ... 30 V DC

- Current consumption: < 50 mA

- Degree of protection: IP67

- Temperature range: -40 ... 85 °C

- Housing material: plastic

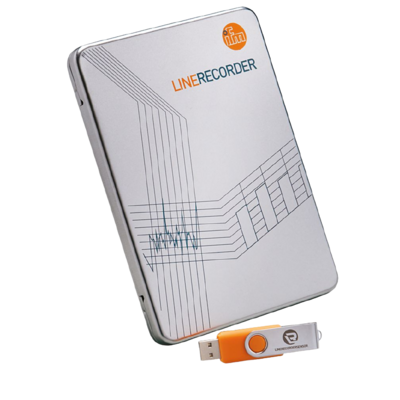

App for parameter setting and set-up of IO-Link sensors, Single user licence included (article no. E71400), Version 1.1.0, Data carrier: USB stick

App for the management of 999 AS-i configurations without special hardware, Single user licence included (article no. E71400), Version 1.0.0, Data carrier: USB stick

Software QA0001

- Operating system: Windows 7, 8.1 or 10 (32-bit or 64-bit)

- Processor: Intel Core i3 or equivalent

- RAM: 4 GB

- Free space on the hard disk: 2 GB

- Interface: USB 2.0

System integration (software)

Condition Monitoring Training

IFM (IFM Electronic) is a global company that specializes in the development and production of industrial automation and control products. Founded in 1969 and headquartered in Essen, Germany, IFM has become an important player in the field of industrial automation. The company does not stand aside from modern techno trends and therefore produces devices compatible with IO-Link. Today we will try to figure out what is IFM software for IO-Link.

Significance of IO-Link Software in Industrial Automation

IO-Link communication is an industrial communication network standard (IEC 61131-9) for the bidirectional exchange of information between IO-Link devices and an IO-Link Master.

The IFM IO-Link software enables convenient and fast parameterization of sensors directly from the workstation. All IO-Link-enabled sensors can be configured regardless of manufacturer. This significantly reduces commissioning time and downtime.

To create "smart" productions, it is necessary to have intelligent sensors at the field level of automation. IO-Link is a key component in creating a smart manufacturing environment. This involves using a large number of field I/O devices and having a network connection to collect data from them. Integrating new equipment through an industrial network is easier at the control level, but more difficult at the field level due to the lack of communication interfaces.

The IO-Link network offers a solution for accessing and exchanging data at the field level with control-level devices. Thanks to IO-Link, it is possible to collect data directly at the sensor level and transfer it to various devices in production. This enables real-time data monitoring and predictive maintenance, reducing downtime and increasing overall operational efficiency. That is why IO-Link has become an important segment in the creation of "smart" production.

Key Features of IFM IO-Link Software

Now, we will look at the main features you get when using IO-Link IFM software.

- Fast and easy integration of intelligent sensors into the PLC world.

- Easy, quick, and intuitive start-up of 1D/2D code readers, 3D cameras, and RFID readers.

- Apps for operation on AS-Interface gateways with Fieldbus interface.

- Simple, clear representation of the process values.

- Shortened set-up time during commissioning.

How to Implement IFM IO-Link Software

Implementing IFM IO-Link software involves several steps to ensure that it works seamlessly with your IO-Link sensors and devices in your industrial automation and control applications. Here's a general guide on how to implement IFM software IO-Link.

Select the right IFM IO-Link software

Choose the IFM IO-Link software solution that best suits your specific needs and is compatible with your IO-Link sensors and devices. Ensure that the software supports the features and functionalities required for your application.

System requirements

Verify that your computer or control system meets the system requirements for the selected IFM IO-Link software. This includes considerations such as operating system compatibility and hardware specifications.

Software installation

Install the IFM IO-Link software on the designated computer or control system. Follow the installation instructions provided with the software.

Connect sensors and devices

Connect your IO-Link sensors and devices to the IO-Link master devices or gateway devices. Ensure that the physical connections are secure and properly configured.

Power up sensors

Power up the IO-Link sensors and devices as per their specifications. Make sure they are receiving the required power supply.

Network configuration

Configure your industrial network to support IO-Link communication. This may involve setting up an industrial Ethernet communication or other suitable communication protocol.

Connect IO-Link master/gateway

Connect the IO-Link master or gateway to your industrial network. Ensure that the master/gateway is properly configured to communicate with your sensors and devices.

Launch IFM IO-Link software

Start the IFM IO-Link software on your computer or control system. The software interface should provide options for discovering and connecting to IO-Link devices.

Device discovery

Use the software to discover the connected IO-Link sensors and devices on the network. The software should identify and list the devices for configuration.

Device configuration

Configure the IO-Link sensors and devices according to your application requirements. This may include setting measurement ranges, thresholds, response times, and other device-specific parameters.

Real-time data monitoring

Utilize the software to monitor real-time data from the connected sensors and devices. This data may include measurements, diagnostics, and status information.

Remote configuration (optional)

If your IFM IO-Link software supports remote configuration, you can adjust sensor settings and parameters from a central location if necessary.

Data logging and analysis (optional)

If your software supports data logging and analysis, configure and use these features to collect historical sensor data for analysis and optimization.

Integration with control systems

Integrate the IFM IO-Link software with your control systems, such as PLCs or HMIs, to enable centralized control and monitoring of IO-Link devices.

Testing and validation

Conduct thorough testing to ensure that the IO-Link sensors and devices are functioning as expected and that data is being accurately captured and processed by the software.

Recap of IFM IO-Link Software Capabilities

IFM Electronic offers IO-Link software solutions to enhance the functionality and usability of their IO-Link-compatible sensors and devices in industrial automation applications. Here are key capabilities you might find in IFM IO-Link software.

Device configuration and parameterization

IFM's IO-Link software allows users to configure and customize the settings of IO-Link sensors and devices. This includes adjusting measurement ranges, sensitivity, and other device-specific parameters to suit specific application requirements.

Real-time data access

IFM IO-Link software provides real-time access to sensor data, enabling users to monitor and collect data from sensors and devices as events occur on the factory floor.

Remote device configuration

Remote configuration capabilities allow users to make adjustments to sensor settings from a central control location. This can be especially useful for devices in hard-to-reach or hazardous locations.

Diagnostics and maintenance

IFM's IO-Link software offers diagnostic tools that assist in identifying and addressing issues with connected sensors and devices. This helps reduce downtime and simplifies maintenance procedures.

Device identification and tracking

IO-Link enables a unique identification of devices within the network. IFM software facilitates device tracking, making it easier to manage and replace sensors when necessary.

Data logging and analysis

Some IFM IO-Link software solutions support data logging and analysis, allowing users to capture historical sensor data for process optimization, quality control, and predictive maintenance.

Integration with control systems

IFM IO-Link software can seamlessly integrate with programmable logic controllers (PLCs) and human-machine interfaces (HMIs) for centralized control and monitoring of IO-Link devices.

Customization

Depending on the specific software solution, IFM may provide customization options to tailor the software to meet unique application requirements.

Firmware updates

IO-Link software may offer firmware update capabilities for IO-Link devices. This ensures that devices remain up-to-date with the latest features and improvements.

Device compatibility and interoperability

IFM's IO-Link software is designed to be compatible with their range of IO-Link sensors and devices, ensuring seamless interoperability within the IFM ecosystem.

User-friendly interface

IFM typically provides a user-friendly interface for their IO-Link software, making it accessible to both engineers and technicians.

Documentation and support

You always can get professional IFM IO-Link support to assist you in effectively implementing and utilizing their IO-Link software and devices.

If you want to get more information, you can always contact Eltra Trade managers. Our experienced employees are ready to answer all your questions and help you choose the right equipment and software for it.