IFM Plugs and sockets

IN STOCK!!!

Socket, AC/DC, M12 connector, Free from halogen

ADOAH040MSS0005H04

- Socket, AC/DC

- M12 connector

- Free from halogen

- Socket, AC/DC

- M12 connector

- Free from halogen

ICE2040-FBOA/OTEIL/IC0003

ICE3040-FPKG/OTEIL/IC5005

Wirable socket, DC, M23 connector,

Y CONNECTION CABLE

Socket, M23 connector, Free from halogen

Socket, M23 connector, Free from halogen

Socket, M23 connector, Free from halogen

Socket, M23 connector, Free from halogen

Socket, M23 connector, Free from halogen

Socket, M23 connector, Free from halogen

Socket, M23 connector, Free from halogen

Socket, M23 connector, Free from halogen

Socket, M23 connector, Free from halogen

Socket, M23 connector, Free from halogen

Socket, M23 connector, Free from halogen

Socket, AC/DC, M12 connector

ADOGH050MSS0060C05

ASTAN040VAS0050P04

Socket, AC/DC, M12 connector,

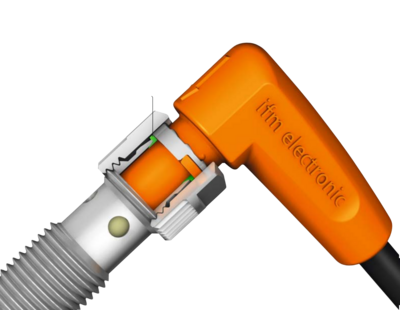

ifm plug wiring

Compatibility:

- With all types of 1.5 mm² PVC cables.

- With all types of sockets and switches.

ifm rewireable plug

- Body: polypropylene (PP)

- Contacts: brass

- Insulation: polyamide (PA)

Socket, AC/DC, M12 connector,

Cable plugs are often used to connect sensors and actuators with connection terminals to junction boxes or modules in the network.

Even when fixed by hand, the properties of a strong and closed sealing of the splitters and connections. They have high protection against penetration of moisture and high resistance of the material to aggressive liquids.

IFM plugs are specially designed for use in hygienic and wet areas. They are resistant to frequent high-pressure cleaning with aggressive cleaning agents. Due to their temperature range and insensitivity to rapid temperature changes, the cable plugs are specially designed for use in the pulp and beverage industry.

Sockets are typically used in automatic machines to connect sensors and actuators with connectors to junction boxes.

Even with manual attachment, a robust sensor and actuator connection is ideal. Even in harsh industrial environments, connectors are protected against unintentional disconnection from exposure protection. Some types include highly visible LEDs to indicate operation and transition status.

IFM sockets are needed for use in hygienic and wet areas. The couplings are resistant to frequent high-pressure cleaning with aggressive cleaning agents. Their temperature range and insensitivity to rapid temperature changes make them particularly suitable for industrial and fruit production applications.

IFM Plugs and Sockets Benefits

Now, let’s look at some IFM plugs and sockets benefits:

- For industrial applications: High-quality materials adapted to the requirements of industrial environments.

- For hygienic and wet areas: Housings and cables made of PVC, gold contacts and high-grade stainless steel nuts are the best prerequisites for long life in the special applications of the hygienic and food industry.

- For oils and coolants: With PUR housing, cable with full PUR sheath, Viton seals, and gold contacts, these products set new standards for the harsh operating conditions of the machine tool industry.

- For sensors in robust applications: The saw tooth contoured vibration protection secures against strong shocks and vibrations. The high protection rating IP 67 / IP 68 / IP 69K, the wide temperature range of -40...90 °C as well as high-quality housing materials (high-grade stainless steel, TPU) ensure a long-term safe connection in harsh environments such as salty moisture, oil, grease, and coolants.

- For electromagnetic fields: In welding equipment weld-slag resistant, halogen-free PUR cables and coupling nuts with special coating provide maximum protection from weld spatter. A special polyester fleece strip foil in the cable ensures long life even in case of high torsional stress, for example in robot arms.

- For hazardous areas: The connectors comply with the strict requirements of the standard and are therefore allowed for use in ATEX areas. Approval body DEKRA EXAM, notified in Germany, has type-tested and certified the connectors.