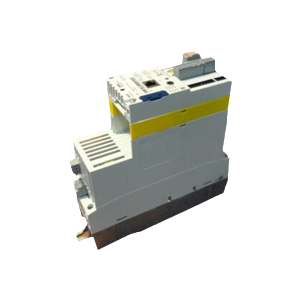

Lenze 8400 High Line

FI 8400 HighLine Inverter

Frequency inverter

8400 HighLine frequency inverters for easy motion and positioning control.

- 11 kw

- 5.8 kg

Lenze 8400 HighLine three-phase frequency converter.

Lenze 8400 HighLine frequency converter.

- The power range is 0.37 kW ... 45 kW

- The supply voltage is 200/230 V (1ph) or 400/480 V (3ph)

- The frequency of the supply voltage is 50/60 Hz

Lenze 8400 StateLine C Series AC Frequency Inverter for 1.5kW (2HP) 230V 1 Ph motor in VxF or Flux Vector control to 7.0A

Lenze 8400 E84AVS E84AVSCE2512 drive

The E84AVSCE7514SX0 series 8400 StateLine 0.25 ... 45kW, design installation

To regulate the operation of an asynchronous motor in order to prevent a decrease in its efficiency, special devices are used - frequency converters. Their job is that they smoothly change the speed of rotation of the engine by changing the frequency of the supply voltage.

Lenze 8400 HighLine drive is designed for speed control in simple motion control supplement as well as stationing enclosures. The requirements of the Green Design Recommendation are fully met.

A frequency converter is an electronical system for changing the frequency of an electric current. Frequency converters are used in industry to check the pace of turning of asynchronous engines. The rotation speed is controlled by changing the frequency of the mover produce strain.

How does a frequency converter work?

The rule of operation of frequency control is based on the relation of the turning rate and torque on the AC motor shaft on the frequency of the produce tension. Periodicity regulators change the frequency of the stress applicable to the electrical engine, thus adjusting the speed of rotation of the rotor and the moment of force.

Areas of use:

- dividing tables

- storage systems (intralogistics)

- forming, filling and capping machines (packaging industry), etc.

Due to the converter, a variety of parameters of the electric motor can be controlled - for example, this is the setting of torque, exit energy, tension change, shaft speed and much more.

Types of frequency inverters

Periodicity transducers differ in design, principle of operation, method of control.

By design, Lenze frequency converters are separated into two large groups:

- Electromachine frequency converters. Electric machine or induction freak reformers are AC engines included in the generator mode. Such electrical devices are used relatively rarely, in conditions where it is difficult or impossible to use electronic frequency converters.

- Electronic transformers. Quasi-conductor periodicity transducers consist of a power section made on transistors or thyristors, and a control circuit based on microcontrollers. This electrical equipment is suitable for three-stage and one-leg drives for any purpose. A distinction is made between direct connection to the mains and devices with an intermediate DC link.

Advantages of Lenze 8400 High Line

The main benefits of 8400 HighLine series are:

- Saving electricity. The use of frequency converters makes it possible to reduce starting currents and regulate the power consumption of the motor depending on the actual load.

- Extending the service life of industrial equipment. Soft start and speed control of the torque on the shaft allow to increase the overhaul interval and extend the life of the electric motors. Opportunity to refuse reducers, throttling valves, electromagnetic brakes and other control equipment that reduces reliability and increases equipment power consumption.

- No need for maintenance. Frequency converters have no moving parts that need regular cleaning and lubrication.

- The ability to remotely control and monitor the parameters of equipment with an electric drive. Many frequency converters have the ability to connect remote telemetry and telemechanics devices; they can be built into multilevel automation systems.

- Wide engine power range. Frequency converters are installed both on single-phase capacitor motors with a power of less than 1 kW, and on synchronous electric machines with a power of tens of MW.

- Protection of the electric motor from accidents and abnormal modes of operation. Frequency converters are equipped with defense contrary overburdens, small chains, stage collapse. The converters also provide a restart when power is restored after a power outage. Possibility of stepless fine adjustment of the speed without power loss, which is not possible with gearboxes.

- Reducing the noise level of the running engine. Possibility of replacing DC motors with asynchronous electric machines with frequency controllers. For equipment requiring torque and velocity monitoring, DC engines are often used, the speed of which is proportional to the applied voltage.

You can buy full model range of Lenze 8400 at the best price with Eltra Trade company. Contact our managers to get a quote.