Common Problems with Solenoid Valves and How to Fix Them

14.10.2025

If you work with HVAC systems, industrial automation, irrigation, or pneumatics, you probably have encountered the situation when the solenoid valve not working at the most inopportune moment. In my experience, most failures are not due to a “bad” brand or defect, but to three main factors: mechanics, electricity, and the working fluid environment.

In this article, I have compiled a solenoid valve troubleshooting guide that will help you quickly understand the cause of the malfunction and solve it without unnecessary costs. It describes how to fix solenoid valve, real cases from field conditions, as well as provides step-by-step checks and prevention tips.

Main points:

● Most solenoid valve failures are mechanical, electrical, or fluid-related.

● This guide covers the top 6 problems and how to fix them fast.

● Includes diagnostics, fixes, and field-proven prevention tips.

● Written by an engineer who’s dealt with irrigation systems, HVAC loops, and pneumatic actuators.

● Quick reference tables, diagrams, and pro tips included.

Why Solenoid Valves Fail:

Mechanical, Electrical, and Fluid Factors

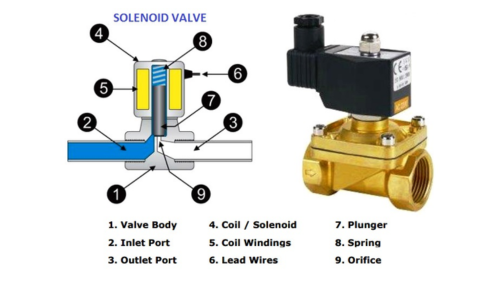

At first glance, the design of a solenoid valve is simple: the coil creates a magnetic field, the core moves, opening or closing the passage of the medium. But it is precisely in this simplicity that a lot of nuances are hidden, due to which solenoid valve problems appear.

Three root causes of failures:

● Mechanical – jamming of the stem, wear of the seat, as well as dirt ingress, and damage to the seals.

● Electrical – coil breakage, poor contacts, or incorrect voltage.

● Hydraulic/pneumatic – low pressure, cavitation, and incorrect flow direction.

At real sites, I have often seen that the valve does not open, not because the coil burned out, but because the system is dirty and the core physically does not move. In other cases, the problem was trivial in the fact that the installers connected an alternating voltage to the DC valve. Therefore, you always need to understand the whole picture.

Top 6 Most Common Solenoid Valve Problems (And How to Fix Them)

In practice, I have often noticed that most problems are related to the same scenarios. Below, I have collected the most typical breakdowns that technicians and engineers encounter and described methods for their diagnostics, repair, and prevention.

1. Valve Not Opening (or Stays Closed)

If the valve not opening or closing, the system does not respond to the power supply, and there is no flow. This is usually due to a power failure, a burnt coil, or a jammed plunger. I always start checking by measuring the voltage and listening for a click. If there is no click, the coil is damaged; if there is, the problem is contamination or pressure. For prevention, you should install filters and monitor the pressure to ensure that the valve's operating range matches the pressure.

2. Valve Not Closing Fully (Dripping or Leaking)

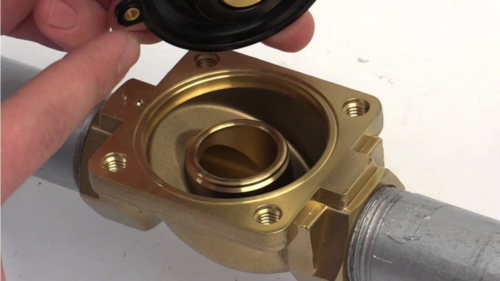

With such a malfunction, the valve begins to leak even without a power supply. Here, contamination, wear of seals, or damage to the seat are to blame. We must carry out a visual inspection after disassembly. In most cases, replacing the seal solves the problem, but with severe corrosion, it is easier to replace the entire valve. To avoid leaks, you should check the quality of the working environment and use filters.

3. Burned-Out Coil

Solenoid coil failure is easy to recognize: the coil does not respond, overheats, and may smell like burning. Most often, this is caused by overvoltage or improper connection. If we check with a multimeter, it will immediately show a break or a short circuit. There is only one solution – replacing the coil. To extend the service life, you can install overvoltage protection and monitor the correct connection.

4. Humming or Noisy Operation

A noisy solenoid valve gives itself away by buzzing or vibrating during operation. The reasons are voltage fluctuations, poor installation, or a loose plunger fit. To check, we need to conduct a test from another source and evaluate the fasteners. Here, reconfiguring the power supply and installing shock-absorbing pads will help you.

5. Sticking or Jammed Plunger

A stuck solenoid valve occurs when there is dirt, corrosion, or scale. The plunger moves with effort, and the valve does not always operate. To diagnose, you need to disassemble and clean the valve. In mild cases, lubrication helps, but with severe wear, replacement is necessary. To avoid recurrence, you should carry out regular maintenance.

6. Low Pressure or No Flow (Even When Energized)

Sometimes the valve clicks, but there is no pressure. Most often, the reason is clogged channels or an incorrect selection of the model for the system. Diagnostics comes down to the fact that you need to measure the pressure before and after the valve and compare it with the passport. If the parameters do not match, you need to replace the valve with a suitable one. Here, you need to rely on the troubleshooting guide and correctly calculate the operating conditions.

+ Bonus

Intermittent Failures or False Triggering

Sometimes the valve will act erratically: sometimes it opens, sometimes it stays closed, or it responds at the wrong time. This behavior is often caused by voltage fluctuations, poor contact at the terminals, or interference in the control circuit. To check, I always start by inspecting the wiring and measuring the voltage under load. If the problem is not in the power supply, you should check the control circuit and eliminate interference.

Valve Overheating

Overheating is manifested by the coil becoming too hot even with normal voltage. In some cases, this leads to failure and valve failure. The main causes are too long switching cycles, high ambient temperatures, or constant voltage above the nominal value. It is easy to check: measure the temperature of the coil and compare it with the rated value. If the heating exceeds the norm, I advise either switching to a valve with a higher insulation class or changing the operating mode to prevent the coil from being continuously held under load.

Troubleshooting Checklist for Solenoid Valves

I always keep a quick diagnostic algorithm on hand:

1. Check the voltage at the coil.

2. Listen for a click.

3. Inspect the filter and seat.

4. Test the valve manually.

5. Check for corrosion and overheating.

6. Replace the coil or the entire valve if necessary.

When to Replace vs Repair a Solenoid Valve

Sometimes you will only need to replace the coil, and there are cases when repair does not make sense.

I always recommend replacing the entire valve if:

● The core is scored.

● The seat is badly damaged.

● The body is cracked.

In other cases, you can limit yourself to repairing the coil or seal.

Tips for Preventing Solenoid Valve Failures

To avoid the constant need for water solenoid valve repair, you should immediately take the right measures:

● Install varistors and diodes to protect against overvoltage.

● Install filters and screens for liquids and gases.

● Monitor the voltage and duty cycle.

● Mount the valves vertically.

● Avoid continuous switching on in hot conditions.

Such pneumatic system optimization and proper operation will extend the service life of the equipment several times.

FAQs About Solenoid Valve Maintenance

1. Can I manually open a solenoid valve?

Yes, most models have a button or lever that will allow you to manually open them for testing.

2. What causes solenoids to burn out?

Most often, the cause is incorrect voltage or overheating.

3. How do I know if my solenoid valve is AC or DC?

You need to look at the marking on the coil - it always indicates the type.

4. What’s the lifespan of a typical solenoid?

On average, 1-3 million cycles, but with proper operation, longer.

5. Are solenoid valves repairable?

Yes, the seals and coil can usually be replaced. But if the housing is damaged, it will be more profitable for you to replace the entire unit.