Electromagnetic Flow Meter Working Principle: Explained by a Process Engineer

08.12.2025

Electromagnetic flowmeters have long been the standard in industrial automation, especially where the flow of conductive liquids needs to be measured. Understanding the electromagnetic flow meter operating principle has come in handy many times in water treatment plants, chemical processing lines, and sludge feed lines, and I can say it's crucial for ensuring accurate and reliable operation. These devices measure flow without moving parts, reducing wear and simplifying maintenance, but they do require attention to the conductivity of the liquid and proper installation.

In this article, we'll cover the following points:

- What electromagnetic flow meters measure – and what they don’t;

- How Faraday’s Law explains their operation;

- Internal parts: electrodes, coils, liners, and transmitter;

- Best uses: water treatment, chemical dosing, wastewater, slurries;

- Includes diagrams, wiring tips, and installation guidelines.

What Is an Electromagnetic Flow Meter?

The electromagnetic flow meter is designed to measure the flow rate of conductive liquids without the use of mechanical components. Unlike turbine or ultrasonic flow meters, it has no moving parts, making it resistant to contamination and ideal for measuring sludge, suspensions, and wastewater.

I used the flow meter for water treatment in raw water supply lines, where measurement accuracy was critical for chemical dosing. Compared to mechanical and ultrasonic flow meters, electromagnetic devices demonstrate stable operation even with high suspended solids content.

How Does an Electromagnetic Flow Meter Work?

Let's answer the question, “How does an electromagnetic flow meter work?”.

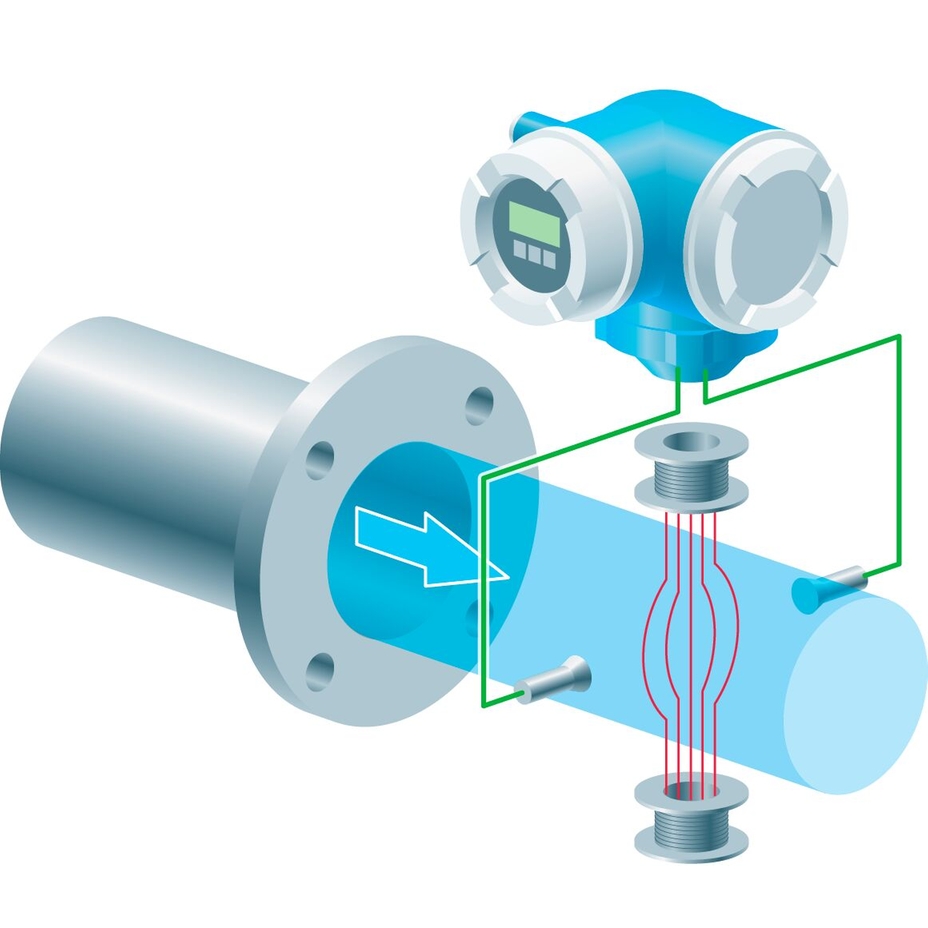

The operating principle is based on Faraday's Law: when a conducting fluid moves through a magnetic field, a voltage is induced in the conducting fluid. This voltage is proportional to the fluid's velocity and the cross-sectional area of the pipe. Simply put, a Faraday's law flow meter converts the kinetic energy of the flow into an electrical signal, which is read by a transducer.

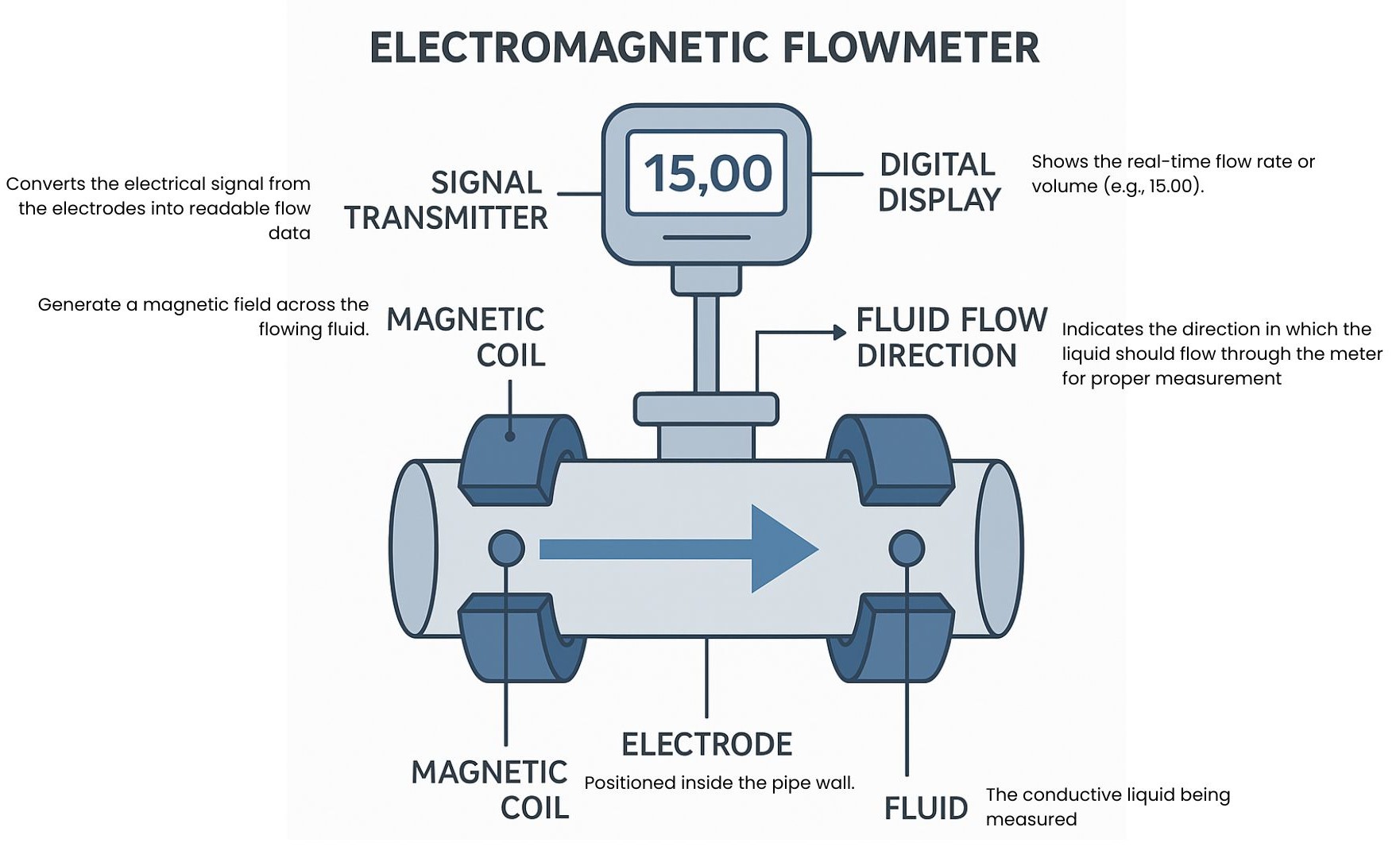

Key internal components

The magmeter contains several critical components, without which the device would not function:

- Magnetic coils create a magnetic field in the tube;

- Electrodes contact the liquid and collect the induced voltage;

- Flow tube and liner protect the internal components from aggressive environments and ensure stable flow;

- Transmitter electronics amplify and process the signal, outputting it in 4-20 mA, pulse, or digital HART/Modbus formats.

Signal processing and output

After generating the signal, the converter eliminates noise and filters fluctuations, ensuring correct flow direction and accuracy. This is especially important for magnetic flow sensors, where even small air bubbles or non-conductive inclusions can create false readings.

Output signals can be analog (4-20 mA), pulse, or digital via HART/Modbus. In practice, I always test the signal on an empty pipe before startup to ensure the magmeter principle of operation is correct.

When to Use an Electromagnetic Flow Meter (and When Not To)

These flowmeters are ideal for:

- Water and wastewater systems;

- Chemical solutions and acids;

- Slurries and suspensions with high conductivity (>5 μS/cm)

These meters should not be used for:

- Oil;

- Gas;

- Non-conductive liquids.

The meters are sensitive to cavitation, air bubbles, and insufficient conductivity. I once encountered errors on a line where the liquid conductivity was too low, causing the meter to display unstable values, highlighting the importance of meeting minimum requirements.

Installation Tips for Electromagnetic Flow Meters

In practice, I always do a preliminary test without liquid to ensure that the electromagnetic flowmeter installation is done correctly:

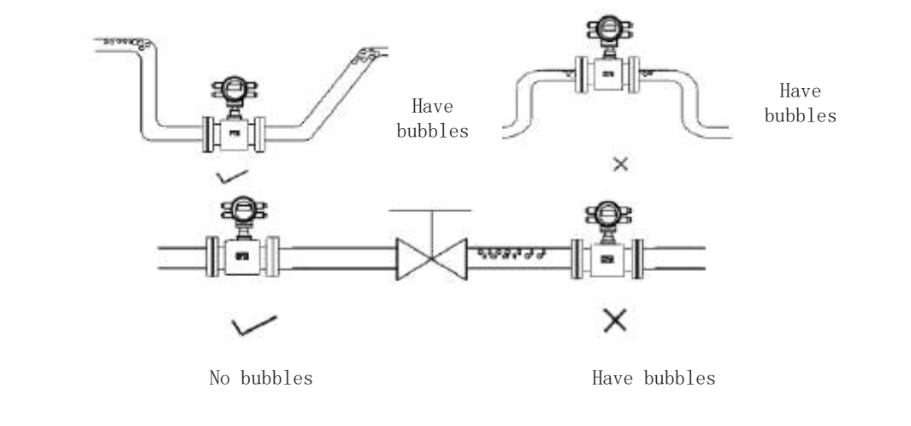

- Pipe orientation: vertical vs. horizontal. Proper pipe orientation is crucial for proper operation of the electromagnetic flow meter. I always try to install the device so that the liquid flow is upward or horizontal, avoiding an upside-down position, which can lead to the formation of air pockets. In practice, vertical installation is acceptable, but only if the flow is strictly upward and the pipes are completely filled with liquid; otherwise, the signals become unstable. Horizontal installation is preferable for long pipelines, where it is easier to monitor grounding and flow purity.

- Grounding rings and electrode exposure. Grounding rings help prevent signal distortion caused by pipe potential or external electromagnetic interference. I always ensure that the magnetic flow sensor electrodes are completely immersed in the liquid and do not touch the pipeline; otherwise, false readings will occur. Proper grounding is especially important in industrial lines with frequent current pulsations and alternating potentials between pipeline sections.

- Avoiding air bubbles and empty pipe faults. Air bubbles and incomplete filling of the pipe will reduce the flow meter's accuracy. In the field, I usually conduct a test run at minimum flow rate to ensure the meter responds correctly and doesn't falsely register zero flow. If there's a risk of bubble formation, it's helpful to install a degasser or maintain a vertical section of pipe before the electromagnetic flowmeter.

- Straight run requirements before and after the meter. For stable flow measurements, it's important to maintain straight pipe sections before and after the electromagnetic flowmeter installation. I always leave at least 5-10 pipe diameters before the electromagnetic flowmeter and 3-5 pipe diameters after it to avoid turbulence and flow fluctuations. This is especially critical at bends, tees, and near pumps, where flow can be unstable and create noise in the signal.

Real-World Examples from the Field

I've installed magmeters in:

- Dosing lines in water treatment plants, where 0.5% accuracy is critical for chemical balance;

- Polymer feed lines in chemical plants, where the flow of viscous liquids is unstable;

- Slurry lines in mining facilities, where mechanical sensors quickly failed.

Every time, the device showed stable results as long as the conductivity and installation requirements were met. This confirms that a flow meter for conductive liquids is the best choice for industrial applications where the liquid contains particles or suspended solids.

Electromagnetic Flow Meter Pros and Cons

Now, let's look at the pros and cons of flow meters.

Advantages:

- No pressure drop. One of the main advantages of electromagnetic flow meters is the lack of flow resistance. This is especially important in long pipelines and low-pressure systems, where any additional pressure drop reduces pump efficiency and increases equipment wear.

- High accuracy, low maintenance. The measurement accuracy of magmeters is typically in the range of 0.5-1%, making them indispensable for chemical dosing and water flow monitoring. Magnetic flow sensors have no moving parts, reducing maintenance and extending their service life.

- Long service life. Thanks to the durable pipe lining and wear-resistant electrodes, the flow meter can operate for decades without replacing parts. In practice, I have seen properly installed magmeters reliably measure aggressive chemical solutions and suspensions on industrial lines for over 15 years.

Limitations:

- Only works with conductive media. The main disadvantage is that the magmeter can only work with conductive liquids. If the medium is non-conductive (oil, gas, organic solvents), the meter will not give accurate readings. This is important to consider when choosing industrial flow meter types.

- Sensitive to air bubbles and grounding issues. Air bubbles and grounding problems cause signal instability. I always recommend installing grounding rings and checking for air in the pipeline after startup or maintenance to avoid false readings.

- Installation constraints. Magmeters require straight pipe sections before and after installation to accurately measure flow. Ignoring these requirements can cause fluctuations and instability in readings, even with the most accurate magnetic flow sensors.

FAQs About Magmeters

1. Can I use a magmeter on oil or gas?

No. Flow meters only work with conductive media. Magmeters are not suitable for oil, gas, or non-conductive solutions, and for such media, an ultrasonic or turbine flow meter is better.

2. What happens if the conductivity is too low?

If the liquid conductivity is below a minimum threshold (usually 5 μS/cm), the signals become unstable, zero-flow errors occur, and the meter may give incorrect readings. In such cases, it is necessary to either increase the conductivity or use an alternative device.

3. How accurate are electromagnetic flow meters?

With proper installation and minimum conductivity, the accuracy is typically 0.5-1% of the measured flow rate. In practice, with the correct magmeter operation principle, I have achieved stable repeatability of readings even on chemical lines with slurry flows.

4. Do magmeters need calibration?

Yes, calibration is required to maintain accuracy. Typically, I check for zero flow, the correct signal on the reference fluid, and the output data compliance with the 4-20 mA standard or digital protocol. This ensures that the electromagnetic flow meter will function correctly.

5. Can I install one upside down or vertically?

Vertical installation is acceptable, but the flow direction should be upward to prevent an empty pipe and air from reaching the electrodes. Turning the magmeter upside down can cause incorrect readings and alarm errors. On all installations, I check the orientation and liquid flow to ensure the electromagnetic flow meter is functioning correctly.