Endress+Hauser Flow Meter Working Principle (Explained by a Field Engineer)

05.11.2025

In industrial automation, accurate measurement of liquid and gas flows plays a critical role in process control, production optimization, and safety. Having worked with Endress+Hauser equipment in chemical plants, food processing plants, and energy facilities, I can say that understanding the Endress+Hauser flow meter operating principle is key to efficient system operation and maintenance. In this article, I will cover in detail the operating principles, device types, applications in various industries, and also share practical installation and calibration tips.

Here's what we'll cover:

- What Endress+Hauser devices do and where they are used: mass and volume flow monitoring, flow velocity, dosing system support, and industrial liquid metering;

- Main technologies: Coriolis, magnetic, ultrasonic, and vortex;

- A simple breakdown of the E&H flow meter principle of each type: from mechanical vibration to induction and ultrasonic time-of-flight;

- Applications: water, chemical solutions, oil, suspensions, and gases;

- Practical experience: examples of setup and operation in industrial environments.

What Does an Endress+Hauser Flow Meter Measure?

An Endress+Hauser flow meter measures three parameters: volume flow, mass flow, and flow velocity. Volume flow allows for accurate metering of the supplied liquid, for example, in water treatment plants or cold water supply systems. Mass flow is especially important in the chemical and food processing industries, where accurate component dosing is critical to product formulation. Flow velocity is used to control the speed of the medium in pipelines and prevent water hammer or cavitation.

Accurate flow control is directly related to pricing, process safety, and precise dosing in production lines. In chemical plants, I have observed cases where incorrect flow meter settings resulted in excessive consumption of expensive reagents, while in food processing plants, inaccurate calibration prevented compliance with CIP/SIP standards and compromised product quality. Therefore, a thorough understanding of how Endress+Hauser flow meters work is essential for every engineer.

What Are the Main Types of Endress+Hauser Flow Meters?

Various Endress Hauser instrumentation allow for solutions across a wide range of conditions and fluid types. Below, I'll discuss each type in detail.

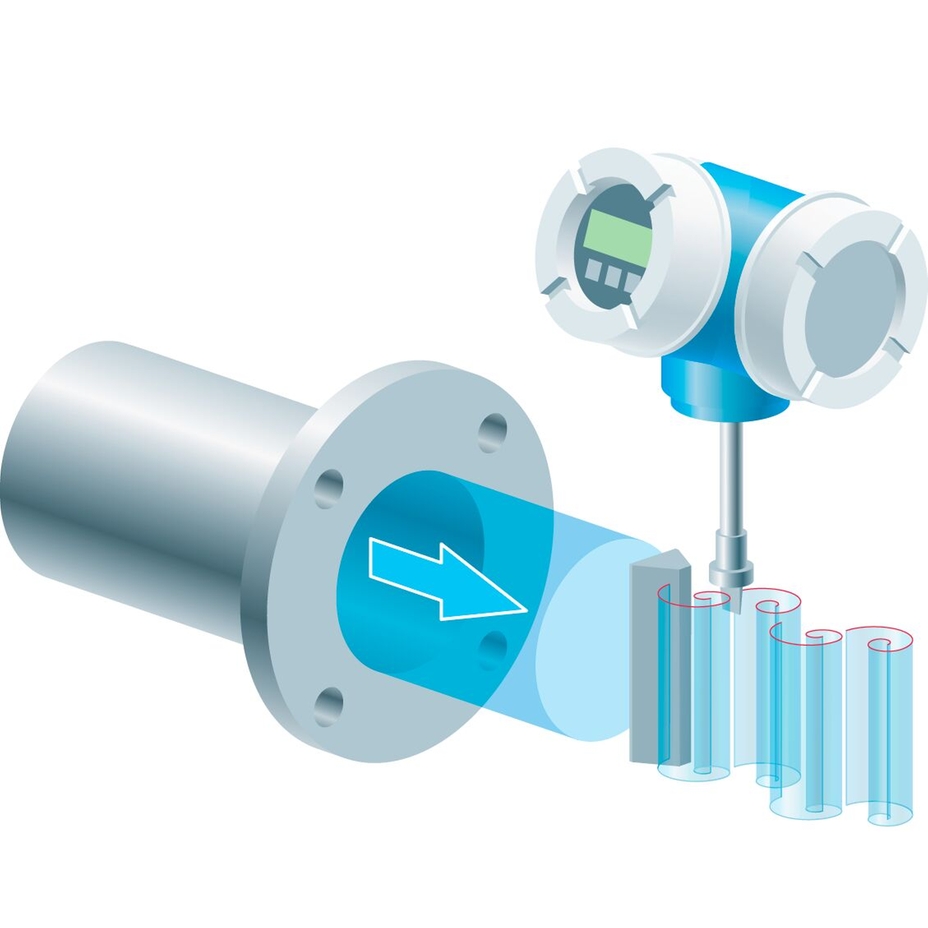

Coriolis Flow Meters (Proline Promass Series)

The Endress Hauser Coriolis flow meter measures mass flow directly using the Coriolis effect. This type is especially valuable when working with viscous, dense, or non-conductive fluids.

In industry, I used the Promass 83 for precise resin dosing at a chemical plant –

the device ensured batch-by-batch accuracy, which is critical for high-precision mixing processes.

The advantages of Coriolis meters include direct measurement of liquid mass and density, and independence from pressure and temperature. Primary applications include mixing, dosing, quality control, and laboratory applications.

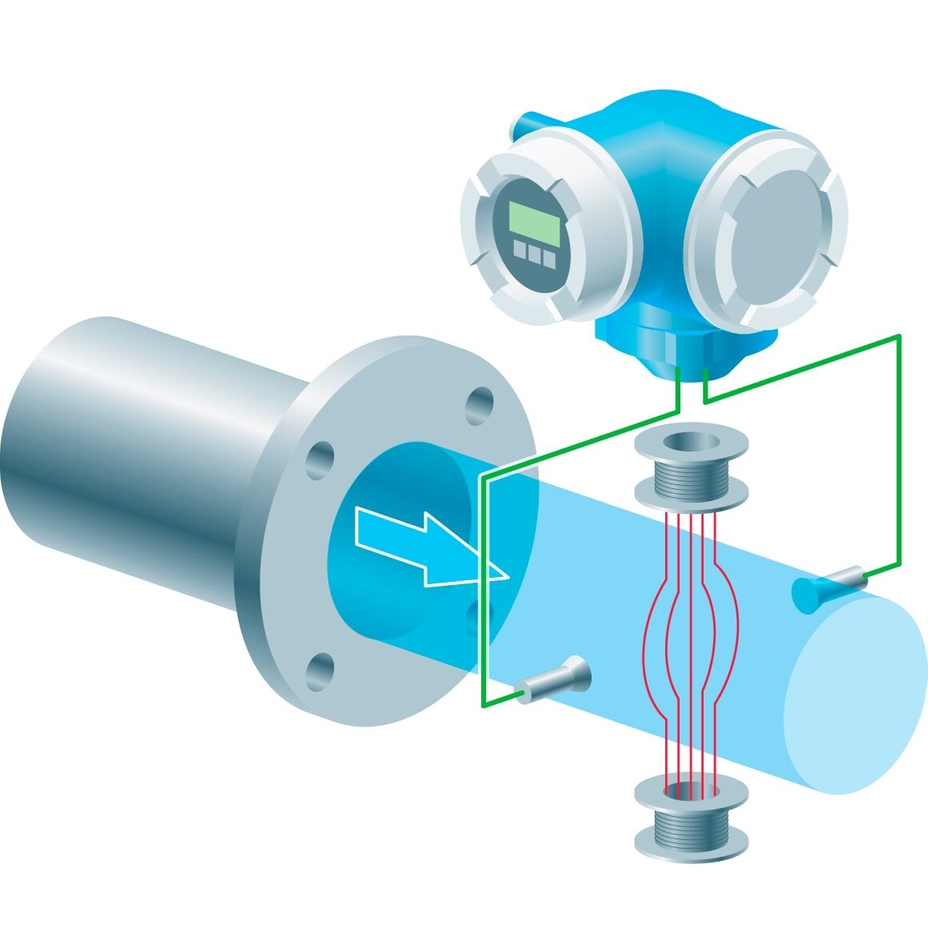

Electromagnetic Flow Meters (Proline Promag Series)

The Endress Hauser electromagnetic flow meter operates on the principle of Faraday's law: a conductive liquid passing through a magnetic field induces an electrical signal. These meters have no moving parts, create minimal pressure drop, and are ideal for wastewater, drinking water, and the pulp and paper industry.

I installed the Promag in a raw water line where suspended solids and potential scale were present – the meter maintained its accuracy and functionality without the need for frequent maintenance. Magnetic flow meters require conductive fluids and are not suitable for oil or pure organic solvents.

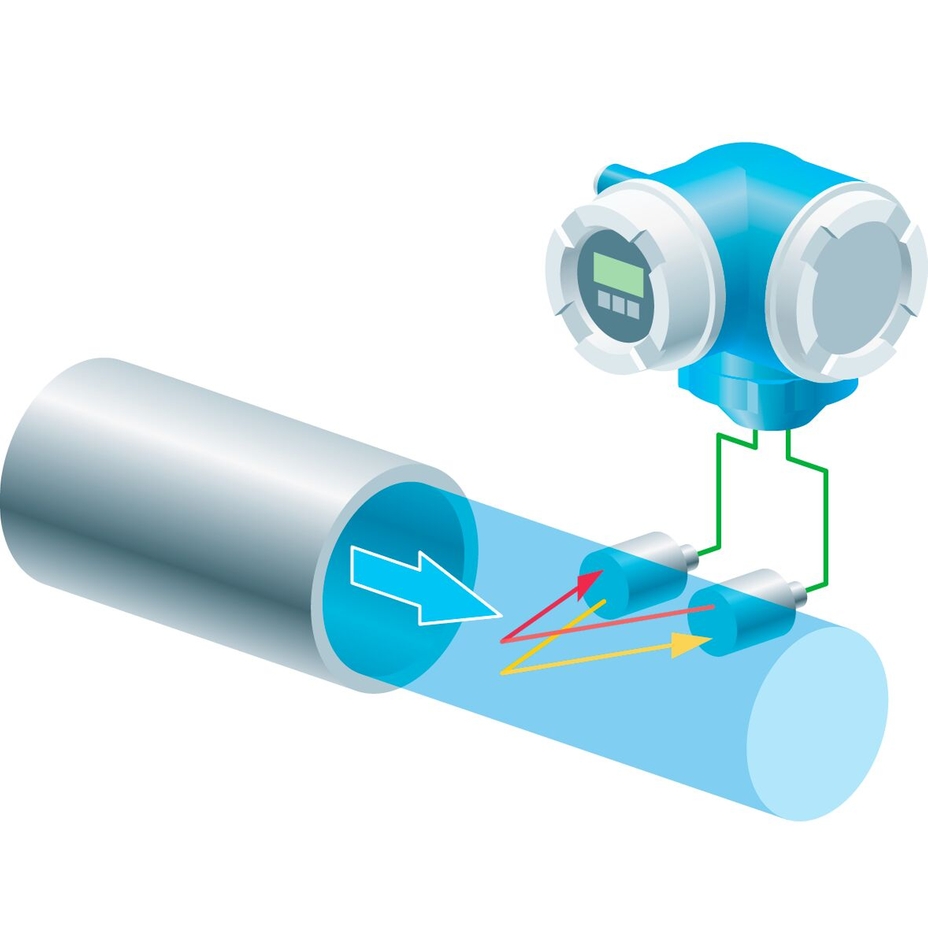

Ultrasonic Flow Meters (Proline Prosonic Series)

The Endress Hauser ultrasonic flow meter measures flow using the time-of-flight method or the Doppler effect. These meters are ideal for large pipelines and non-invasive installation on existing lines. I've used the Prosonic for HVAC and hot/cold water supply systems at municipal heating network facilities.

The main advantages include non-invasive installation and the ability to install on existing pipelines without cutting the line. It's important to consider straight pipe sections: at least 10 diameters upstream and 5 diameters downstream.

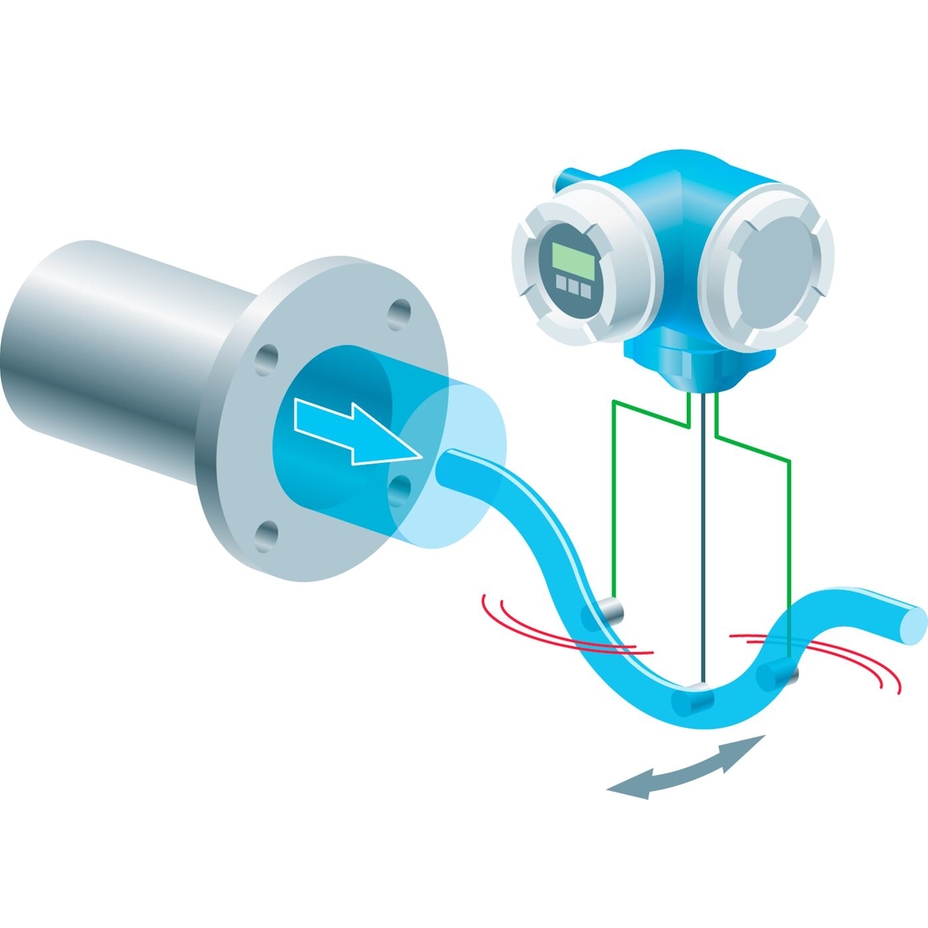

Vortex Flow Meters (Proline Prowirl Series)

Vortex Flow Meters detect vortices formed behind a baffle in a flow. These devices are suitable for measuring steam, gases, and aggressive liquids, and feature built-in pressure and temperature compensation.

I've used Prowirl on steam and gas pipelines where it was necessary to monitor both mass and volume flow simultaneously. Vortex flow meters are convenient for measuring turbulent flow, but accuracy decreases at low flow rates.

How Do These Flow Meters Work? (Simple Breakdown)

Every E+H device uses a different industrial flow meter working principle, which affects their accuracy and application areas. Coriolis flowmeters rely on tube vibration to measure the mass and density of a fluid through its deformation under the flow. Magnetic flowmeters use electromagnetic induction for conductive fluids. Ultrasonic flowmeters analyze the signal's transit time through the flow, while vortex flowmeters analyze the frequency of vortex formation.

Signals from these flowmeters can be represented as 4-20 mA, pulses, HART, or Profibus, enabling integration with automation systems. When calibrating, it is important to consider the zero point and correct pressure/temperature compensation. This approach ensures reliable and repeatable readings – the basis for proper operation in real-world production.

Endress+Hauser Flow Meter Applications by Industry

Now, I'd like to tell you about the flowmeters used in various industries:

- Water and wastewater: Promag – drinking and raw water flow measurement;

- Chemical and petrochemical industries: Promass, Prowirl – precise dosing of reagents and steam;

- Food and pharmaceutical industries: Promass (CIP/SIP safe) – ingredient and formulation control;

- Power and steam: Prowirl + pressure modules – turbine flow control;

- HVAC and building automation: Prosonic clamp-on – heat transfer fluid and cooling liquid control.

Pros and Cons of Each Flow Meter Type

For a more visual comparison of all the advantages and disadvantages of the different flow meter types Endress Hauser, I have compiled a table:

Flow Meter Type | Best For | Pros | Limitations |

Coriolis

| Liquids/gases with high accuracy | Direct mass flow, density | Expensive, heavy |

Magnetic | Conductive liquids | No moving parts, reliable | Can’t measure non-conductive |

Ultrasonic | Large pipes, retrofit | Non-intrusive, versatile | Accuracy depends on the installation |

Vortex | Steam/gas | Handles high temps/pressures | Not ideal for low flow |

Installation and Calibration Tips (From the Field)

Proper installation is the key to accuracy. For vortex and ultrasonic flowmeters, a straight section of pipe is required, while avoiding vibration and interference. The horizontal or vertical orientation of the pipe affects signal accuracy, especially for Coriolis.

For calibration, I always use FieldCare or a HART communicator, checking the cable connections and EMI protection, as even minor electrical interference can distort readings. Secure mounting and vibration-free operation are critical for the long-term stability of an industrial flow meter.

How to Choose the Right E+H Flow Meter for Your Application

By following this flow meter selection guide, you can choose the right device for your needs:

- Determine the fluid type: conductive, gas, or viscous;

- Choose between volumetric or mass flow;

- Consider the pipe diameter and installation space;

- Determine accuracy and resolution requirements;

- Check output signal compatibility;

- Consider operating pressure and temperature;

- Match the model with the following requirements: Promag, Promass, Prosonic, Prowirl.

FAQs About Endress+Hauser Flow Meters

1. Can a magnetic flow meter measure gas?

No, magnetic devices only work with conductive liquids.

2. Which flow meter is best for batching?

Coriolis (Promass) provides the highest dosing accuracy.

3.Do I need straight pipe runs with ultrasonic meters?

Yes, at least 10 diameters upstream and 5 downstream.

4. Are Endress+Hauser meters explosion-proof?

Many models are ATEX/IECEx certified; check the data sheet.

5. How do I calibrate an E+H flow meter?

Use FieldCare or the local calibration menu, depending on the model.