Hohner Encoders: Features, Applications, and Selection Guide

05.02.2026

In the world of modern industrial automation, precision is a must. When it comes to reliable motion, speed, and position control, Hohner encoders are often my first choice as an engineer. This brand has established itself as a manufacturer capable of ensuring stable equipment operation even in the most hostile environments. Whether you're designing a new conveyor line or looking for a replacement for a failed encoder, it's important to understand the nuances of each line.

The best way to find out more about specific encoder models and their respective specifications is by reviewing Hohner’s encoder catalog. There, you will find solutions available that suit every application.

Before we look into the specifics of the technical section, here are some highlights of Hohner's encoder product line that make them unique:

- Overview of Hohner’s encoder lineup: incremental, absolute, hollow shaft, solid shaft;

- Where these encoders shine: CNCs, conveyors, packaging, robotics;

- Key specs that matter: PPR, housing, signal type, shaft style;

- Tips from real installations: what to check before ordering;

- Catalog link included – easy access to model selection.

Who Is Hohner and Why Their Encoders Stand Out

Hohner is a company that has been in business for a long time and is well established in the area of feedback technology. The company began in the 1980's and has grown into a worldwide organization serving the industrial automation sector.

The main reason that Hohner encoders are different from many other encoder manufacturers is the strength of their products. Many other manufacturers have attempted to achieve their price point by using plastic housings rather than stronger alternatives. Hohner has refused to do this and has chosen to build a quality product using heavy-duty metal housings and very fine-bearing materials. This is the primary reason Hohner has gained such a strong following in the European market for industrial automation.

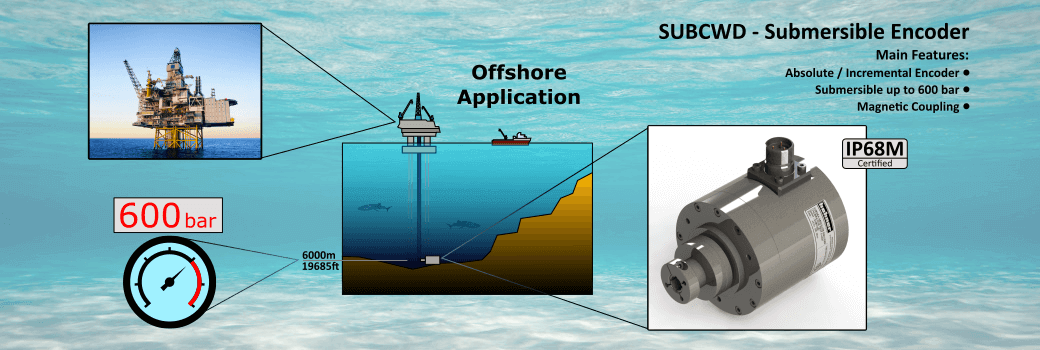

Their products are certified to international safety and quality standards. Particular attention is paid to operation in harsh environments: high humidity, vibration, extreme temperatures, and abrasive dust are no obstacle for a properly selected Hohner sensor.

Overview of Hohner Encoder Types

The choice of the right encoder type is the first step to a successful project. The company's products are divided into several main categories based on their reading method and mechanics. Each Hohner rotary encoder is designed to withstand specific operating loads. Let’s check what the Hohner encoder catalog offers us.

Incremental encoders

Incremental encoders generate pulses in response to shaft rotation. They are ideal for measuring speed or relative displacement. A typical incremental encoder Hohner has channels A, B, and Z (an index channel for determining the zero point). The PPR (pulses per revolution) ranges from a few to tens of thousands, enabling incredible accuracy. These devices are most commonly found in electric drives, motors, and simple conveyor belts.

Absolute encoders

Unlike incremental models, the Hohner absolute encoder "remembers" its position even after power is lost. This is achieved by creating a unique code for each shaft position. Single-turn and multi-turn versions are available. Single-turn models record position over 360 degrees, while multi-turn models can track the number of complete rotation cycles. This is critical for robotics, elevator systems, and complex CNC machines, where losing coordinates during a power failure is unacceptable.

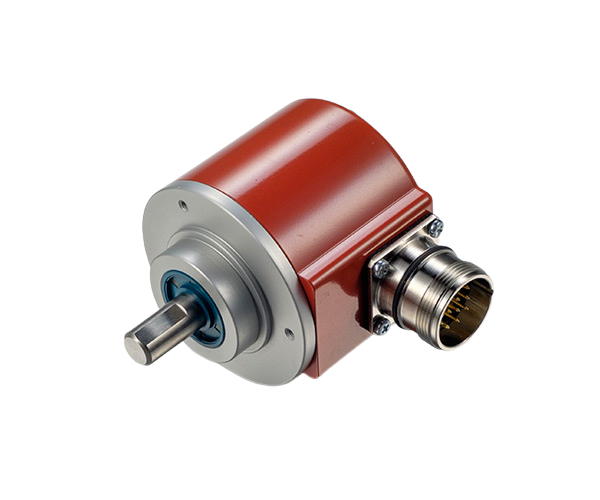

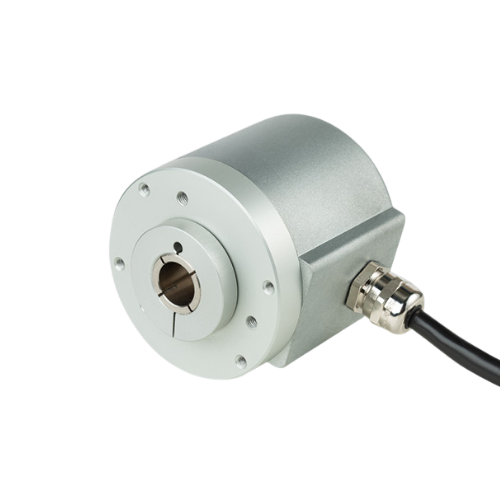

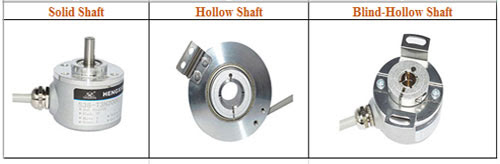

Solid shaft vs hollow shaft options

Mechanical design also plays a crucial role. Solid shaft models are typically mounted via a coupling, providing excellent isolation from motor vibration. Hollow shafts are mounted directly to the drive shaft, saving space in the cabinet or installation.

Common Use Cases for Hohner Encoders

The design's flexibility allows this encoder for industrial automation to be used in virtually any industry. Here are the main areas:

1. Industrial packaging and labeling. Speed and synchronization are crucial. Sensors help accurately measure film length or position labels on bottles. The high resolution of Hohner models minimizes errors when cutting materials at high speeds, significantly reducing defects. This is especially critical in flow-packing lines, where the slightest misalignment can lead to packaging damage.

2. Conveyor belt control. Precisely monitors the speed of goods to prevent jams and optimize logistics. The integration of an encoder with a frequency converter maintains a stable torque when the belt load changes. In complex sorting units, this ensures that each item is dropped into the correct bin at a precisely specified time.

3. Robotics. Absolute sensors in the manipulator joints ensure millimeter-level movement accuracy. Because Hohner absolute models "remember" their coordinates when powered off, the system eliminates the need for a cyclical zero-point search (homing). This significantly reduces line recovery time after emergency shutdowns or power outages;

4. Elevator systems and lifts. Cabin height control and smooth stopping. The use of high-resolution sensors ensures smooth cabin alignment with the floor. The robust mechanical design withstands constant axial loads typical of winches and traction mechanisms, ensuring passenger safety;

5. Agricultural machinery and mobile equipment. Specially designed, ruggedized series operate in mud and under severe vibration. Thanks to stainless steel housings and reinforced bearings, these units maintain accuracy even in direct contact with fertilizer or during high-pressure washing. In precision farming systems, they ensure uniform seed placement, adapting the flow rate to the current tractor speed.

Key Specs to Look For When Choosing a Hohner Encoder

The right choice starts with reading the documentation. This brief Hohner encoder selection guide will help you avoid missing important details:

- Resolution (PPR). Determines how many pulses the sensor produces per revolution. For precise positioning, select higher values;

- Output format. TTL (5V), HTL (10-30V), or RS422. This must match your controller (PLC);

- Protection rating (IP). IP65 is sufficient for cleanrooms, but IP67 is better for work with coolant or outdoors;

- Shaft type and size. Ensure the shaft diameter matches your equipment (metric or imperial dimensions);

- Connection type. Cable (fixed length) or connector (easier for maintenance).

Solid vs Hollow Shaft – Which Hohner Encoder Should You Choose?

The choice between a solid or hollow shaft often sparks debate among installers. Each shaft encoder Hohner has its own advantages.

Parameter Solid Shaft Hollow Shaft

- Mounting Requires a flexible coupling and mounting bracket. Mounted directly onto the drive shaft with a collar.

- Dimensions Occupies more axial space due to the coupling. Compact design, ideal for integrated motor assemblies.

- Resistance Superior protection against high axial/radial loads. Sensitive to shaft runout and motor vibrations.

- Cost Efficiency Lower unit price but higher installation hardware cost. Higher unit price, but eliminates the need for extra parts.

Practical advice: In tight control cabinets and compact units, I always choose models with a hollow shaft. This eliminates the need to center the coupling, which is a real pain in the ass in tight spaces.

Wiring and Installation Advice from the Field

Even the most expensive sensor will fail if connected incorrectly. Here are a few rules to help avoid downtime:

1. Shielding. Always use shielded cable. The shield should be grounded at only one end (usually the controller end) to avoid ground loops;

2. Grounding. Ensure that the equipment housing and the sensor housing have reliable electrical contact with a common ground busbar;

3. Alignment. When using a solid shaft, the slightest misalignment of the coupling will cause rapid bearing wear. Use flexible couplings to compensate for micro-movements;

4. Torsion arms. For models with a hollow shaft, be sure to use a locking spring or torque arm to prevent the housing from rotating with the shaft.

Where to Buy Hohner Encoders Online

When you purchase industrial equipment, it requires trust in the supplier. If you find a reliable industrial encoder supplier, it’s half of the battle. I recommend you consider Eltra Trade. We are official distributor of Hohner Automation and offer transparent terms of cooperation.

By visiting the full catalog, you can find current prices and download a detailed Hohner encoder datasheet for each model you're interested in. Furthermore, the company's technical support can help you find an alternative if your model is no longer in production and arrange for fast delivery.

Final Thoughts: Why I Recommend Hohner in Harsh Applications

My personal experience shows that skimping on feedback sensors often results in huge losses due to line downtime. When I work in a dusty environment or where equipment is subject to constant vibration, Hohner's stainless steel housing has saved me from monthly component replacements more than once.

While there are cheaper Chinese alternatives on the market, Hohner is worth every penny thanks to its durability and signal stability. It's a "set it and forget it" solution for professionals.

FAQs About Hohner Encoders

1. Can I replace my existing encoder with a Hohner one?

Yes, in most cases, this is possible. The main thing is to select the appropriate shaft type, electrical interface, and pulse repetition rate (PPR). The Eltra Trade catalog often includes cross-reference tables.

2. Does Hohner make ATEX-certified encoders?

Yes, the brand has a special line of certified encoders for use in potentially explosive environments (oil and gas, chemical industries).

3. What’s the max PPR available in their lineup?

Standard models support up to 10,000 PPR, but specialized series can support significantly higher values for ultra-precise applications.

4. How do I choose between TTL and HTL outputs?

TTL uses 5V logic and is suitable for short distances and high-speed applications. HTL operates in the 10-30V range, is more noise-resistant, and allows signal transmission over longer distances (up to 100 meters).

5. Can I use Hohner encoders in outdoor environments?

Yes, if you choose a model with an IP67 protection rating and a stainless steel housing. They handle temperature fluctuations and precipitation well.