Incremental vs Absolute Encoders: Which One Should You Use? (Engineer’s Comparison Guide)

22.01.2026

If you've ever adjusted a servo drive or tried to "catch zero" on a CNC machine after the lights went out in the shop, you know that the encoder is the "eyes" of your control system. In my experience, I've seen hundreds of burned-out controllers and messed-up settings.

Most often, problems arose because someone tried to save a few hundred dollars during the design stage or simply didn't fully understand the incremental vs absolute encoder differences in real-world conditions. In this article, we'll break it all down: from operating principles to specific selection tips.

Today we will discuss:

● What incremental and absolute encoders do – explained simply;

● Core difference: relative position vs true position;

● Startup behavior, wiring, cost, and reliability compared;

● Real-world use cases from motors, robotics, and CNC systems;

● Includes comparison tables, pros/cons, and selection tips.

What Do Encoders Do in Motion Control Systems?

In any modern automation system, we rely on feedback.

Without it, a controller is a blind driver. To accurately control speed, position, or torque, we need reliable encoder feedback systems.

In a closed-loop system, the encoder informs the PLC or motor driver precisely where the shaft is located. If you use a stepper motor in an open-loop system, you simply hope it takes the required number of steps. However, if a step stalls or is missed, the system won't be aware. That's why in serious equipment, from packaging lines to elevators, feedback is a matter not only of accuracy but also of safety.

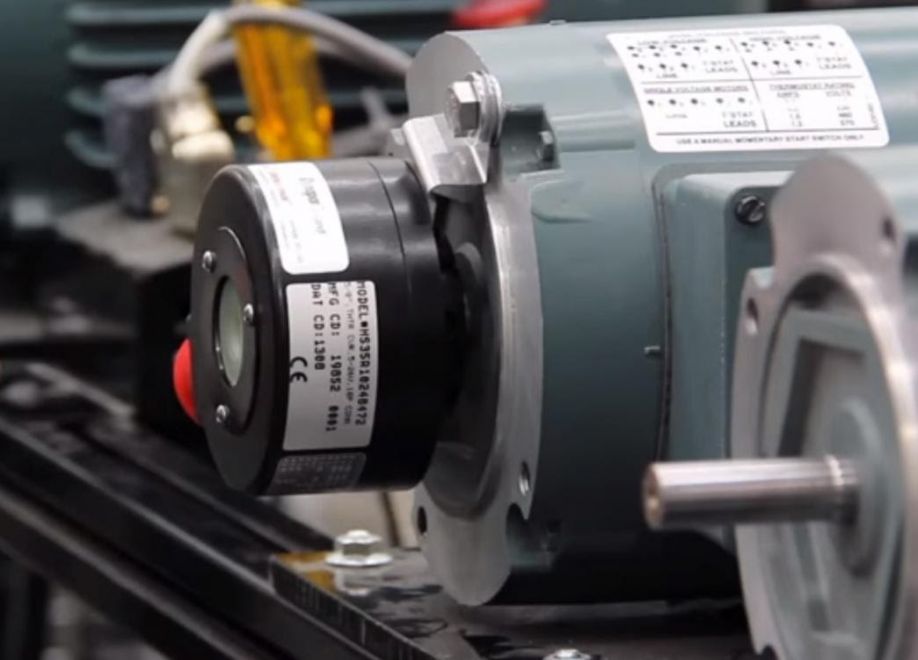

What Is an Incremental Encoder?

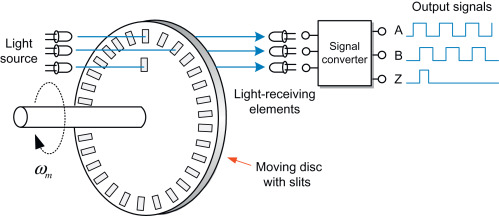

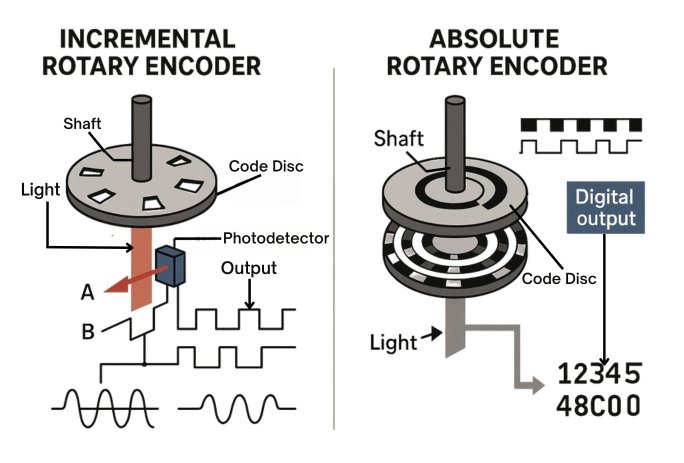

This is the most common type of sensor. In short, the incremental encoder working principle is to generate a certain number of pulses for each shaft revolution.

It typically produces two main signals – phases A and B. They are offset by 90 degrees (quadrature). This allows the controller to determine whether the shaft is rotating and in which direction it is rotating. There is also almost always a Z-index channel – one short pulse per complete revolution, which serves as a physical zero point.

The main characteristic of every incremental encoder is data loss when power is turned off. Imagine counting steps while climbing in the dark. If you get distracted and forget the number, you have to go back to the very bottom (to the "home" position) to start counting again. This is why systems with such sensors always require a homing procedure (searching for the home position) each time they are powered on or after an emergency stop.

What Is an Absolute Encoder?

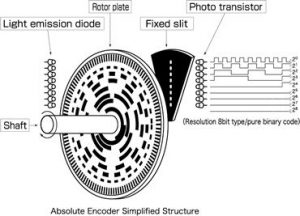

The mechanics and logic here are completely different.

This device doesn't count pulses; it reports a unique digital code for each angular position of the shaft. If the absolute encoder working principle is correct, it's like a ruler with markings. Inside it is a disk with a complex pattern (Gray code or binary code). When the controller polls the encoder, it instantly returns the value: "I am at 45.3 degrees".

Single-turn vs multi-turn

● Single-turn encoders. They know the position within one revolution (0-360 degrees). If the shaft completes two revolutions, the encoder will again show the same values as on the first revolution.

● Multi-turn encoders. They have an additional mechanism (gears or electronic memory) that counts the number of complete revolutions. This is critical for linear axes, where the motor shaft makes tens or hundreds of revolutions to move the carriage.

The main advantage is memory. If you turn off the machine, rotate the shaft by hand 90 degrees, and turn the power back on, the absolute encoder will immediately show the new correct position. No "trips home" required.

Incremental vs Absolute Encoders – Key Differences Compared

When people ask me what the main difference is between incremental and absolute encoders, I usually show them this table. It helps quickly assess the impact on a project.

Feature Incremental Encoder Absolute Encoder

Feature | Incremental Encoder | Absolute Encoder |

Position on startup | Unknown | Always known |

Homing required | Yes | No |

Wiring complexity | Simple | More complex |

Cost | Lower | Higher |

Failure recovery | Limited | Strong |

Typical applications | Conveyors, fans | Robotics, CNC |

When choosing between these solutions, you're essentially choosing between a low price now and saving time (and money) on maintenance later. These are the main encoder types in automation, covering 99% of tasks.

When I Choose an Incremental Encoder (And Why)

I use incremental encoders in projects where the budget is limited, and the system requirements allow for minor adjustments at startup.

Main scenarios:

● Simple conveyors. If the belt simply needs to rotate at a set speed, and we don't care where exactly a link stalls;

● Pumps and fans. Here, we're only interested in the rotational speed (RPM), not the rotation angle;

● Systems with infrequent shutdowns. If the machine runs 24/7 and a monthly homing procedure isn't a problem;

● High-speed applications. At very high speeds, simple pulses are sometimes easier to process than polling a complex digital protocol.

In simple dosing or winding systems, this is an excellent way to save money without sacrificing process reliability.

When I Choose an Absolute Encoder (And Why)

There are situations where I don't even consider other options. If a positioning error can lead to damage to an expensive tool or injury, there are no alternatives.

My recommendations:

● Robotics. Imagine a six-axis manipulator. If it forgets its coordinates, it could crash into a fence or itself while trying to find its "home";

● Complex CNC machines. Where tool positioning takes a long time;

● Elevators and lifts. The system must know exactly what floor the cabin is on, even if power has just been restored after a failure;

● Multi-axis synchronous systems. Where multiple motors must operate in strict coordination.

If your line downtime costs thousands of dollars per hour, then overpaying for an absolute encoder is the best insurance you can buy.

Installation & Wiring Differences You Should Know

Installation is where field engineers make the most mistakes:

● An incremental encoder is very sensitive to electromagnetic interference (EMC). If you run the encoder cable next to the VFD power cable without proper shielding, the controller will begin to pick up "phantom" pulses. As a result, your carriage will gradually drift away from the true zero.

● An absolute encoder uses digital interfaces (SSI, EnDat, Profinet). They transmit data in packets. If the packet is corrupted, the controller will generate an error, but it won't add an extra meter to the coordinate. However, it's important to properly configure the addressing and termination of the communication line.

A typical mistake I see is using cheap, unshielded incremental encoder cable over long distances (more than 20-30 meters). Believe me, you'll spend more money troubleshooting the cause of the floating zero than on a single, high-quality cable.

How to Choose the Right Encoder for Your Application

To make your life easier, I've put together a step-by-step algorithm. Answer these questions before purchasing:

● Is homing acceptable? If the machine can easily reach the limit switch when powered on, go with an incremental encoder. If not (for example, if there's a load on the shaft), then only an absolute encoder is suitable;

● What happens if power is lost? If this results in defective production, go with an absolute encoder;

● What accuracy is needed? Incremental encoders have a PPR (pulses per revolution) limit. Absolute encoders often offer much higher resolution (up to 20-24 bits);

● What is the environment? If the workshop has significant interference from welding machines, an absolute encoder with a digital protocol will be more stable;

● Budget vs. downtime risk. When evaluating the difference between an incremental and absolute encoder, always weigh the cost of the sensor against the cost of downtime: if one extra homing session after a power failure costs your production more than the difference in price between the devices, the choice in favor of an absolute encoder becomes obvious;

● Controller compatibility. Make sure your PLC supports the selected interface (e.g., SSI input).

The correct servo motor encoder selection is always a compromise between technical necessity and common sense.

Common Myths About Incremental and Absolute Encoders

Now, I'd like to point out a few common myths about encoders:

● Myth 1: "Absolute encoders are always better". This isn't always true. They are more complex to configure and harder to replace on-the-fly with a device from another brand due to software compatibility;

● Myth 2: "Incremental encoders are inaccurate". This is not true. The accuracy (resolution) can be the same. The only difference is in the way this information is stored;

● Myth 3: "Absolute encoders don't require configuration". They do. You still need to program the offset to align the software zero with the mechanical shaft position.

Final Recommendation from the Field

My advice is simple: if you're doing a simple task like "running a conveyor belt," keep it simple and use a reliable incremental encoder.

But if you're designing a positioning system, especially a multi-axis one, my answer to the question "which encoder should I use" is unequivocal: absolute. Modern trends in Industry 4.0 are making diagnostics and instant equipment availability more important than saving on components.

FAQs About Incremental vs Absolute Encoders

1. Can I replace an incremental encoder with an absolute one?

Mechanically, yes, but you'll have to completely rewrite the logic in the controller and possibly replace the PLC input modules.

2. Do absolute encoders need batteries?

Mechanical multi-turn encoders (gear-based) – no. Electronic ones (with memory) are sometimes needed to store the number of revolutions when the power is off.

3. Is homing always bad?

In simple machines, this is normal. In complex systems, it a risk of failure, and it wastes time.

4. Which encoder is better for servo motors?

The modern standard is absolute. This allows the servo drive to instantly know the rotor position for optimal control of the winding currents.

5. What fails more often in real-world installations?

Their mechanics are roughly the same. However, incremental encoders are more likely to suffer from "glitches" due to interference, which is mistaken for a failure of the encoder itself.