Innomotics - Innovative Strength and Reliability

22.11.2024

High-voltage motors are essential for applications needing significant power output in industrial settings. These motors guarantee seamless and continuous operations whether they are powering compressors, pumps, conveyors, or massive manufacturing machinery. They are perfect for industries including manufacturing, mining, oil and gas, and energy production since they can manage heavy loads with little energy loss.

High-voltage motors are not merely instruments in a world that requires greater efficiency and environmentally friendly solutions; they are crucial elements propelling industrial advancement in the future.

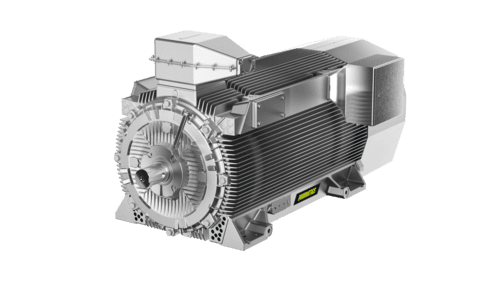

Innomotics – A Leader in High-Voltage Motors

High-voltage motors are the backbone of industrial automation, providing the power required to drive large-scale operations across industries like manufacturing, energy production, and heavy machinery.

Innomotics stands out for its remarkable emphasis on engineering quality and personalized solutions. Innomotics, in contrast to many other manufacturers, creates motors that blend in perfectly with particular industrial applications, guaranteeing peak performance, longevity, and energy efficiency. Innomotics has continuously produced dependable solutions, regardless of the application's severe operating circumstances, heavy loads, or stringent energy-saving specifications.

From an industrial automation perspective, the value of a high-voltage motor lies not only in its ability to handle massive power demands but also in its efficiency and lifecycle cost. Innomotics addresses these priorities by integrating advanced materials, precise engineering techniques, and smart design principles into their products. This results in motors that excel in both performance and sustainability.

For sectors that need strong, effective, and long-lasting high-voltage motors, Innomotics is a reliable partner due to their unmatched experience and creative approach. Innomotics provides a comprehensive solution to drive advancement for industries looking to streamline their processes, not simply motors.

Innomotics Motor Technology

Innomotics motor technology combines cutting-edge innovation with robust engineering to deliver reliable, efficient, and sustainable solutions for industrial automation.

1. Advanced Engineering for Optimized Performance

Innomotics motors are built using cutting-edge engineering techniques that maximize efficiency and operational stability. These motors feature precision-engineered components, such as optimized rotors, stators, and magnetic circuits, to deliver consistent performance in even the harshest conditions.

- Energy Efficiency: Reduced energy losses through innovative electromagnetic designs.

- High Power Density: Compact designs with greater output power for space-saving installations.

- Dynamic Stability: Smooth torque delivery for seamless operation, even with fluctuating loads.

2. Use of Premium Materials for Durability

Durability is at the heart of Innomotics motor technology. Every component, from windings to enclosures, is manufactured using high-quality materials to ensure long-term reliability.

- Thermal Resilience: High-performance insulation withstands extreme operating temperatures.

- Corrosion Resistance: Rugged enclosures protect against chemical exposure and environmental wear.

- Reinforced Bearings: Designed for heavy-duty operations with minimal maintenance requirements.

3. Flexible Design for Versatility

Innomotics motors are engineered to cater to a wide range of industrial applications. Their modular and customizable designs make them highly adaptable for varied operational demands.

- Cooling Options: Includes air-cooled, water-cooled, and hybrid cooling systems for optimal heat management.

- Custom Configurations: Flexible mounting, shaft designs, and voltage ranges to suit industry-specific needs.

- Broad Applicability: Suitable for industries such as oil and gas, manufacturing, mining, and energy.

4. Digital Integration for Smart Operations

The integration of smart technologies into Innomotics motors sets them apart in the industrial automation landscape. These motors are equipped with digital tools that enhance monitoring, diagnostics, and operational efficiency.

- IoT-Enabled Monitoring: Real-time data collection for condition-based maintenance and performance tracking.

- Predictive Maintenance: Early fault detection through advanced analytics, reducing unplanned downtime.

- Remote Accessibility: Operators can access motor parameters remotely for instant diagnostics and adjustments.

5. Sustainability in Focus

Innomotics motors are designed with sustainability in mind. By improving energy efficiency and reducing emissions, they support industries in achieving their environmental goals.

- Reduced Carbon Footprint: High-efficiency motors lower energy consumption.

- Eco-Friendly Manufacturing: Components are designed to be recyclable and compliant with global standards.

- Extended Lifespan: Durable designs reduce the need for replacements, minimizing waste.

Types of Siemens Innomotics motors

A wide variety of motors from Innomotics are available; they are divided into distinct types and series, and each one is painstakingly designed to precisely and effectively handle particular operating needs.

Innomotics Low Voltage Motors

1.1 Innomotics GP General Purpose Motors

General Purpose Motors from Innomotics GP are made to handle a variety of common drive applications in commercial settings. Because of their low weight, these motors are perfect for use in lifting apparatus, fans, compressors, pumps, and conveyor technology. They are available in efficiency classifications IE1 through IE4 and have an aluminum housing.

1.2 Innomotics SD Heavy Duty Motors

Innomotics SD Heavy Duty Motors are built with rugged gray cast iron frames, making them suitable for the toughest environmental conditions. They excel in performance under dust loading, vibration, and aggressive atmospheres, such as those found in the petrochemical and process industries. These motors are designed for optimized heat dissipation and easy handling.

1.3 Innomotics XP Explosion Proof Motors

Explosion-proof motors from Innomotics XP are made to operate in potentially explosive environments. Because of their strength and dependability, these motors can operate safely even under the most adverse circumstances. They come in a variety of designs, such as non-sparking (Ex nA IIC) and flameproof (Ex de IIC) enclosures. These motors can be used in compressors, fans, pumps, and other equipment in dangerous conditions.

1.4 Innomotics DP Special Purpose Motors

Special Purpose Motors from Innomotics DP are designed for certain uses that call for particular performance attributes. With their great efficiency and dependability, these motors are made to satisfy the particular needs of different industries.

1.5 Innomotics DP Special Purpose Motors – High Torque Motors

The DP Special Purpose High Torque Motors from Innomotics are made to provide outstanding torque in demanding applications. These motors are perfect for demanding industrial jobs that demand dependable performance because they are designed to produce large amounts of power.

1.6 Innomotics HV C and M Low Voltage Versions

The exceptional efficiency and dependability of Innomotics HV C and M Low Voltage Motors make them ideal for low-voltage applications. These motors provide peak performance and energy savings for a range of industrial applications.

High Voltage Motors

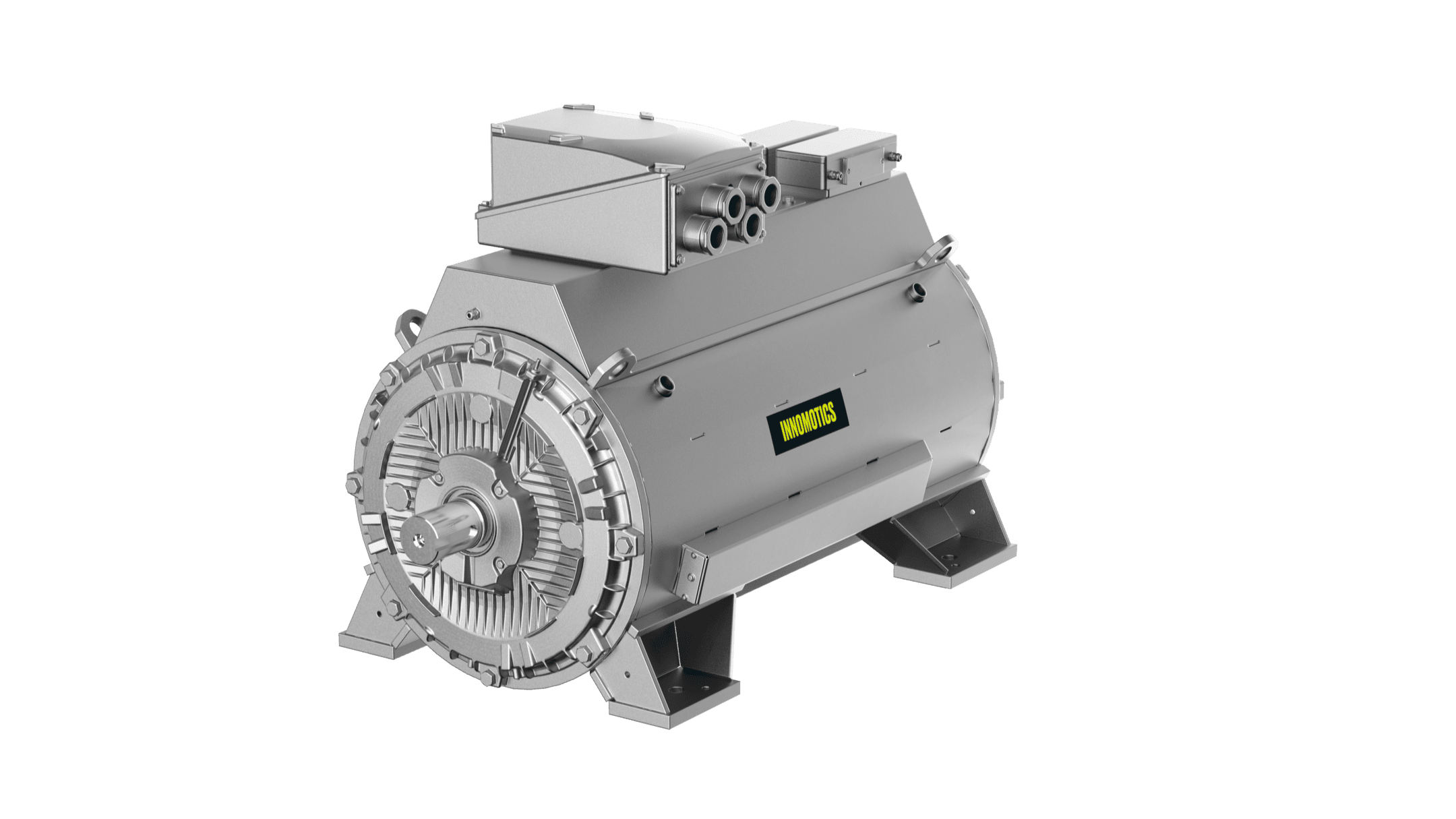

1.1 Compact Motors (IEC)

Compact motors (IEC) are designed to offer high performance in a small footprint. These motors are ideal for applications where space is limited but high efficiency and reliability are essential. They are typically used in industries such as manufacturing, automotive, and processing, where compact design and high power density are critical.

- Innomotics HV C air-cooled

- Innomotics HV C water-jacket-cooled

- Innomotics HV C flameproof

1.2 Modular Motors (IEC)

Modular motors (IEC) are built with a flexible design that allows for easy customization and scalability. They can be adapted to a wide range of applications, from industrial machinery to power generation. The modular nature of these motors simplifies maintenance and upgrades, making them a cost-effective solution for businesses looking to optimize their operations.

- Innomotics HV M

- Innomotics HV M slipring

- Innomotics HV Series A-compact-PLUS

1.3 High Power Motors (IEC)

In demanding applications, high power motors (IEC) are designed to provide outstanding performance. Because of their huge load capacity, these motors are frequently found in heavy industries including steel production, mining, and oil & gas. Even in the most trying circumstances, their dependable performance is guaranteed by their sturdy design and great efficiency.

- Innomotics HV HP

1.4 Specialized Motors (IEC)

IECs, or specialized motors, are made for certain industrial uses that call for particular performance traits. These motors are frequently utilized in specialized sectors where ordinary motors are unable to satisfy the necessary requirements. Motors used in high-speed applications, dangerous situations, and precision control systems are a few examples.

- Innomotics HV Series HS-modyn

- Innomotics HV HS

- Innomotics HV Series Metals

- Innomotics HV Series Mining – Ring Motor

- Innomotics HV Series Mining Conveyor

- Innomotics HV Series Mining Mine Winder

- Innomotics HV Series Energy

1.5 AboveNEMA Motors

AboveNEMA motors are made for uses that go above the National Electrical Manufacturers Association's (NEMA) conventional frame sizes and power ratings. Large industrial applications including power plants, water treatment facilities, and extensive manufacturing processes use these motors because of their tremendous power output. They are appropriate for the most severe operating settings because of their exceptional performance and longevity.

- Innomotics HV AboveNEMA

Innomotics Medium Voltage Drives

1.1 Innomotics Perfect Harmony GH150

The Innomotics Perfect Harmony GH150 is a versatile medium voltage drive designed for applications ranging from 4 to 13.8 kV. It offers high performance, reliability, and efficiency, with options for different cooling methods and cell redundancy to ensure maximum availability.

1.2 Innomotics Perfect Harmony GH180

The Innomotics Perfect Harmony GH180 features a cell-based design that provides high efficiency and availability. It is suitable for a wide range of voltage and output power configurations, making it a flexible solution for various industrial applications.

1.3 Innomotics SH150

The Innomotics SH150 is a vector control variable frequency drive designed for complex applications. It offers a wide range of functions and system versions, making it ideal for marine and other demanding environments.

1.4 Innomotics GM150

The Innomotics GM150 is a universal drive converter for single-motor applications with variable and constant torque characteristics. It is designed for robust and efficient operation without regenerative feedback.

1.5 Innomotics SM150

The Innomotics SM150 is a special-purpose drive ideal for applications with low and high speeds, single and multi-motor systems. It offers high dynamic performance and regenerative capabilities, making it suitable for a wide range of medium voltage applications.

1.6 Innomotics GL150

A medium voltage drive called the Innomotics GL150 was created to provide dependable and effective motion solutions for a range of industries. It is appropriate for severe industrial applications and offers reliable performance.

1.7 Innomotics SL150

The Innomotics SL150 cycloconverter with thyristor stacks is an optimal solution for controlling low-speed, high-torque induction, and synchronous motors. It is designed for extreme environments and is ideal for rolling mills, conveyors, and other heavy-duty applications.

Conclusion

Modern technical techniques and high-quality materials are used in the construction of Innomotics motors to guarantee unparalleled lifetime, performance, and dependability.

By incorporating Innomotics High-Voltage Motors into their systems, industries can improve performance, dependability, and operational efficiency. These motors are more than simply parts; they are essential components that propel innovation and productivity, advancing industrial processes and ensuring their entire success. By selecting Innomotics, you are making an investment in high-quality, dependable, and state-of-the-art technology that will sustain and improve industrial operations for many years to come.