ISO Standards for Pneumatic Cylinders

17.05.2023

Since the transition to machine production, the use of standardized parts has made it possible to dramatically reduce the cost and speed up the production of any product. The pinnacle of unification is standardization. It is a standard product that is future-oriented technology that can work reliably 24 hours a day in any industry.

The greatest number of standard products is presented in the group of movement elements. This group includes pneumatic cylinders. They convert the energy of compressed air into useful mechanical work for moving, lifting, shearing, and clamping with a force proportional to the diameter of the pneumatic cylinder piston and the pressure of the supplied compressed air.

It is represented by a series of standard pneumatic cylinders that meet the requirements of international standards ISO 6432, ISO 15552, and ISO 21287. In this material, we will study in detail what ISO standards are, how such standards are related to pneumatic cylinders, and which specific ISO standards for pneumatic cylinders apply.

What is the ISO Standard for the Pneumatic Cylinder?

ISO standards are introduced to help businesses increase productivity, minimize errors and reduce waste. The purpose of the standards is to support companies in entering new markets and to promote the development of world trade on a fair basis. From the consumer's perspective, ISO standards protect end users by ensuring that certified products meet the minimum standards set internationally.

This approach inevitably involves trade-offs in specific features or performance characteristics but creates a good general-purpose product suitable for many standard applications. However, some industries and applications may have a greater need for certain features or functions, such as a reduced shell or lighter weight: features that give them performance or functionality advantages for a better end solution.

These types of applications can benefit from non-ISO pneumatic cylinder options. Here are some quick and easy guides to ISO Cylinder Standards to help you find and select the right products for your application with confidence to achieve maximum machine performance and a secure and reliable supply chain.

ISO Standards Definition

The abbreviation ISO stands for International Organization for Standardization. It is an organization that is a worldwide federation of national standards organizations.

International standards bring technological, economic, and social benefits. They help to harmonize the technical characteristics of goods and services, make the industry more efficient, and contribute to the removal of barriers to international trade. Compliance with international standards helps convince consumers that products are reliable, efficient, and environmentally friendly.

The benefits of ISO standards for pneumatic cylinders include:

- Cost savings. International standards optimize operations and thus improve the bottom line.

- Expanding customer satisfaction. Standards help improve quality, increase customer satisfaction, and increase sales.

- Access to new markets. ISO standards help overcome trade barriers and open access to global markets.

- Increasing market share. Standards help increase productivity and competitiveness.

- Environmental benefits. ISO standards help reduce environmental impact

Pneumatic Cylinder ISO Standards

Pneumatic cylinders based on ISO standards are the cornerstone for most manufacturers of pneumatic control technology and a popular choice for machine builders in a variety of industries. Let's take a closer look at pneumatic cylinder standards Guide.

ISO 15552 pneumatic cylinders

ISO 15552 profile cylinders are one of the most popular types of cylinders in the industry. The standard specifies the main parameters that manufacturers must follow. It indicates the main dimensions of the cylinder, as well as the dimensions of the hole: in this case, from 32 mm to 320 mm. The dimensions of the mounting interface and attachment accessories, as well as the nominal/recommended stroke, are given.

In addition, there are details on the types of mounting options (such as trunnion mounting), accessories (such as yoke bracket), and damping method. Due to the increased distance between the nose bearing and the piston, this design is overall strong and capable of handling some side loads. With more space in the front end cap, there are many options for scrapers, seals, and bearings to meet different requirements or performances.

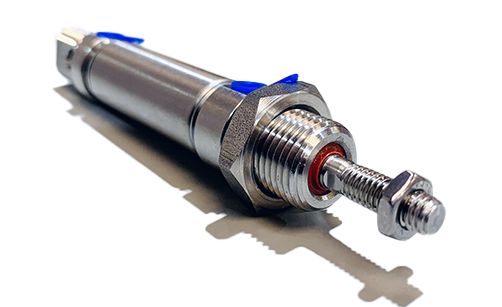

ISO 6432 pneumatic cylinders

ISO 6432 specifies dimensions for round cylinders from 8mm to 25mm, although manufacturers often offer higher diameter ranges up to 80mm or 100mm outside of a specific standard. With lighter weight and built-in mounting interfaces, round cylinders are used in many less demanding applications.

The ISO 6432 Cylinder is a versatile product typically used for simple handling, holding, and lifting. It uses wear-resistant materials for longer life and comes with a wide range of options to best suit the application. Multiple mounting options give it added flexibility making it one of the first choices for customers.

ISO 21287 pneumatic cylinders

ISO 21287 applies to so-called compact or short-stroke cylinders. When using short pistons and front-end caps, they are significantly shorter for the same stroke than in the examples above. Compact ISO cylinders are a great choice when space is tight.

However, this comes with a trade-off: they will not be as strong as standard ISO 15552 profile cylinders and generally should not be subjected to side loads. Guide and more secure options are available for applications such as stoppers on conveyor systems.

And now the most interesting. For pneumatic cylinders made according to ISO 15552 and ISO 21287, the same fasteners (rod ends, forks, hinges, etc.) are used during installation, which is very convenient for both equipment manufacturers and end users.