Rotary Encoder vs Linear Encoder: What’s the Difference?

29.09.2025

When people ask me what the main difference is between a rotary encoder vs a linear encoder, I always start with the simple: they are both position sensing encoders, but the former measures angular movement of a shaft, while the latter measures linear movement along an axis. In production, this choice determines the operation accuracy, how you mount the system, as well as how long it will last, and how expensive the project will be.

In this article, I will analyse the difference between rotary and linear encoder as it looks in practice, not in theory. I will tell you what mistakes I encountered during installation, and also why, sometimes, it’s cheaper to take a rotary sensor, and in other cases, you can’t do without a linear one.

Briefly about what you will learn:

- What do encoders do, and why is feedback needed in motion systems at all?

- What is the difference between the rotary encoder and the linear encoder working principle?

- How to choose between them based on real experience.

- Installation details: from shaft alignment to compensation for thermal expansion.

- Practical advice and FAQ to avoid confusion in choosing.

What’s the Basic Function of an Encoder in Motion Control?

Any precision motion system must be built on the principle of feedback. Without an encoder for motion control, we cannot determine the position of the axis or shaft, and the system begins to operate blindly.

An encoder is a sensor that generates a signal when moving. This signal goes to the controller, which compares the actual position with the command. It turns out to be a closed loop: controller – motor – movement – sensor – signal – controller.

In industry, we can use two main types of output signals:

- Incremental – give pulses when moving, the controller counts them and determines the offset.

- Absolute – immediately report the current position, even after the power is turned off.

In practice, I often encounter incremental models: they are cheaper and simpler, but where safety is important or position reset is impossible, for example, in robots, you cannot do without absolute options.

What Is a Rotary Encoder?

A rotary encoder measures the rotation of the shaft. In essence, it is a disk with marks and a reading device.

When the shaft rotates, the system records the angular displacement.

I have installed them on CNC spindles, servomotors, and conveyor drives. Their strong point is compactness and ease of integration. Even in retrofitting old machines, it’s easier to install a shaft encoder than to try to pull a linear scale.

Typical outputs:

- TTL and HTL – digital pulses.

- Analog – used less often, but sometimes convenient for a smooth signal.

If we talk about rotary encoder applications, these are: engines, actuators, gearboxes, where accounting for revolutions and angular position is important.

What Is a Linear Encoder?

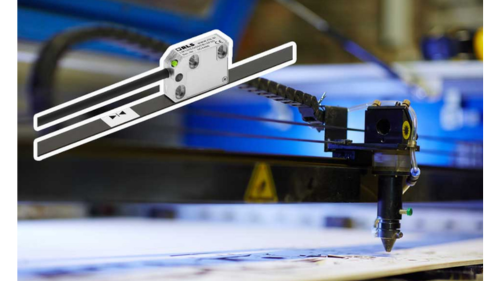

Now, about another type – a linear encoder. Its task is to measure linear movement. Usually, it consists of a scale (glass or magnetic) and a reading head.

Here, it is important for us to understand the linear encoder working principle: the head reads the change in position relative to the scale and produces a signal. Due to this, we can achieve micrometre accuracy.

Types:

● Optical – the most accurate, but afraid of dust.

● Magnetic – more resistant to dirt, but inferior in resolution.

● Capacitive – used in specific conditions.

Where are they used? In axial CNC systems, coordinate tables and measuring devices.

Rotary Encoder vs Linear Encoder: Key Differences Compared

If we compare rotary and linear encoders, we need to understand that these are not just different form factors, but different approaches to measurement.

Feature | Rotary Encoder | Linear Encoder |

Motion Type | Angular | Linear |

Mounting | Shaft or hub | Scale + read head |

Accuracy Range | Medium to high | High |

Use Case | Motors, shafts | Axes, gantries, tools |

Cost (general) | Lower | Higher |

Environmental sealing | Easier to protect | More vulnerable |

When to Use a Rotary Encoder (And Why)

In most of my projects, rotary encoders cover 80% of the tasks. On motors, in actuators, in systems with frequency converters - this is a fast, inexpensive, and reliable option.

Pros:

Compact housing, easy to install on the shaft.

Low price compared to linear ones.

Easy retrofit – especially on old equipment.

Fewer problems with alignment and temperature deformations.

My personal advice: if you are working with a servo drive, pump, fan, or any rotating unit, then a rotary encoder is the first choice. I usually tell customers, "Don't complicate the system where you can put a simple solution."

When to Use a Linear Encoder (And Why)

If I have a task to achieve high accuracy of table or axis movement, I can't do without a linear encoder. In CNC, this means correct coordinate control, and in measuring devices, reliable data.

Why exactly is it?

Eliminates screw transmission errors (backlash).

Provides direct position measurement, not indirectly through the shaft.

Copes well with thermal expansion or deflection of the structure.

In my practice, I installed linear ones where approximately 1 micrometre is needed: granite measuring tables, laser machines, or microscopes. Here, encoders work in tandem: rotary for the motor, linear for the axis.

Installation Considerations: Rotary vs Linear

Mounting an encoder is a separate topic, and this is where you can most often encounter problems. I always take an indicator and a micrometer with me on site – without them, you cannot properly align a linear encoder.

For rotary:

Ensure the alignment of the shaft and the encoder. Any beating will reduce the service life.

Monitor vibrations – use dampers.

Lay the cable to avoid kinks and tension.

For linear:

The most critical part is the alignment of the scale. Even tenths of a millimeter will give an error.

Maintain a constant gap between the head and the scale.

Consider thermal expansion: long scales can “walk” when heated.

Final Recommendation: How to Choose Based on Application

So, how to approach the choice in practice? If you are a beginner, focus on a simple rule: the motor is a rotary encoder, the machine axis is a linear encoder.

Check everything else according to the technical specifications:

Determine the type of movement: rotary or linear.

Set the requirements for accuracy and resolution.

Check the operating conditions: dust, moisture, vibration.

Deciding whether you need absolute or incremental output.

Check compatibility with the controller and interfaces.

FAQs About Encoder Selection

1. Can I use a rotary encoder instead of a linear one?

In some projects, it is indeed possible to replace a rotary encoder with a linear one if the accuracy requirements are low and only the shaft rotation is controlled. But when moving along a straight axis, such a replacement will give errors due to backlash and temperature deformations.

2. What’s more accurate – rotary or linear encoder?

Traditionally, a linear encoder provides higher accuracy, since it measures rectilinear movement without the influence of mechanical clearances.

3. Which is easier to install?

Of course, a rotary encoder is easier to install – it is enough to fix it on the shaft or through a coupling, and it is immediately ready for work.

4. Do I need an encoder with a servo motor?

Yes, an encoder is always needed for the correct operation of the servo; otherwise, the system will not be able to close the feedback loop.

5. Can I use both types in one system?

Yes, a combination is possible and is often found in modern machines and robots. This combination of different encoder types in automation will give the best result when we combine simplicity and accuracy.

Article by Caroline Karol,

Chief Sales Officer of Eltra Trade s.r.o.