Guide Siemens Sinamics Power Module 250 Error Codes for Smooth Production

18.04.2024

In the intricate ecosystem of industrial automation, the Siemens Sinamics Power Module 250 stands as a pinnacle of efficiency and reliability. However, even the most advanced technology can encounter errors and faults. By deciphering the nuances of trouble codes, operators and maintenance personnel can swiftly diagnose issues, apply corrective measures, and implement preventive strategies to mitigate future occurrences. This proactive approach not only enhances operational efficiency but also protects valuable assets and investments. We will delve into the importance of comprehending Power Module 250 fault codes, the methods for correcting them, and the preventive measures to ensure uninterrupted production.

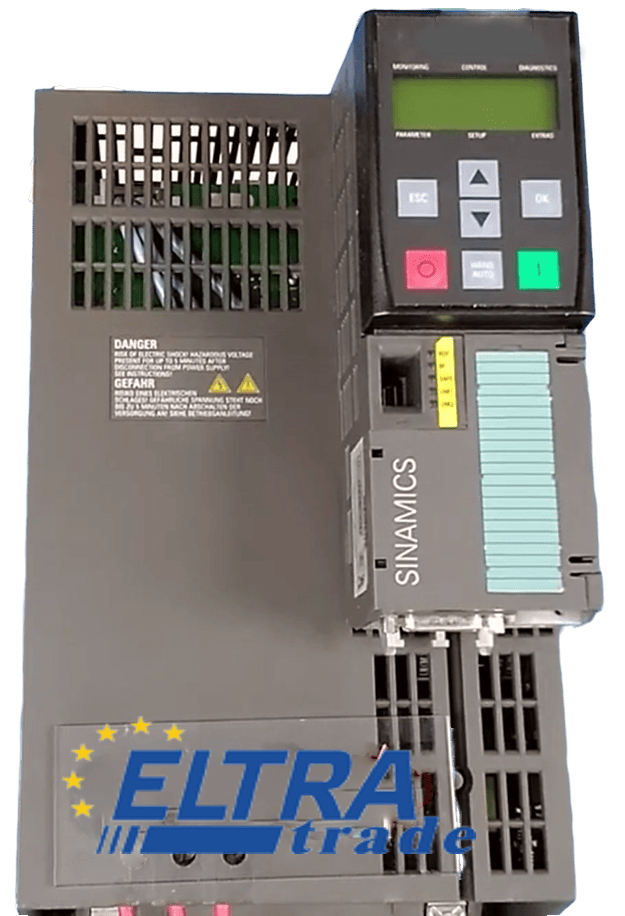

Siemens Sinamics Power Module 250

Sinamics Power Module 250 is a robust, state-of-the-art power converter designed to meet the demanding needs of industrial automation. It serves as the powerhouse behind various motion control applications, ranging from simple conveyor belts to complex robotic systems.

How Does it Work?

At the heart of the Power Module 250 lies advanced semiconductor technology, meticulously engineered to deliver unparalleled performance and reliability. Through sophisticated algorithms and feedback mechanisms, it regulates voltage and frequency with remarkable accuracy, ensuring smooth and efficient operation of connected machinery. Its modular design allows for scalability and flexibility, accommodating diverse applications and configurations with ease.

Importance in Production

The significance of sinamics pm250 in production cannot be overstated. It serves as the backbone of automation systems, driving productivity, and efficiency to new heights. By providing precise control over motor operations, it optimizes energy usage, reduces waste, and enhances overall equipment effectiveness (OEE). Its seamless integration with industrial networks enables real-time monitoring and diagnostics, empowering operators to preemptively address issues and minimize downtime.

In essence, pm250 siemens is not just a component; it's a catalyst for innovation and progress in the manufacturing sector. Its reliability, efficiency, and versatility make it indispensable for businesses striving to stay ahead in today's competitive landscape.

Understanding Fault Codes

Sinamics Power Module 250 fault codes are alphanumeric indicators generated by the system to signal abnormal conditions or malfunctions. These diagnostic trouble codes list, providing invaluable insights into the nature and root causes of errors affecting the module's performance. Each fault code corresponds to a specific issue, enabling maintenance personnel to swiftly pinpoint and address problems with precision.

How Do Fault Codes Occur?

Fault codes typically manifest in response to deviations from normal operating parameters or the detection of system anomalies. These deviations can arise from various factors, including electrical irregularities, mechanical failures, or environmental influences. When the system detects such deviations, it triggers the corresponding fault code to alert operators or maintenance personnel to the issue at hand.

Where are Fault Codes Displayed?

Sinamics Power Module 250 fault codes are prominently displayed on the module's control panel or interface. Depending on the severity of the error and the configuration of the system, fault codes may be accompanied by audible alarms or visual indicators to ensure timely recognition and response. Additionally, some advanced monitoring systems may transmit fault code information to centralized control systems or remote monitoring platforms for real-time analysis and intervention.

Importance of Prompt Recognition and Response

Prompt recognition and response to fault codes are critical for minimizing downtime, preventing potential damage to equipment, and ensuring the continuity of production processes. By promptly addressing fault codes and implementing appropriate corrective actions, operators and maintenance personnel can swiftly restore normalcy to operations and maintain peak efficiency.

Fault codes Siemens Sinamics 250 and their elimination

sinamics pm250 fault codes are diagnostic indicators generated by the system to flag abnormal conditions or malfunctions. These codes provide valuable insights into the nature and root causes of errors affecting the module's operation. Each fault code corresponds to a specific issue, enabling maintenance personnel to pinpoint and rectify problems with precision.

Fault codes list, names and reasons for Siemens Sinamics Power Module 250

| Error Code | Error Name | Cause |

| F001 | Input voltage error | The supply voltage is too high or too low. |

| F002 | Overload | The drive is drawing more current than the power module can supply. |

| F003 | Short circuit | There is a short circuit in the output circuit of the power module. |

| F004 | Overheating | The power module is overheating. |

| F005 | Fan error | The power module fan is not working. |

| F006 | Temperature sensor error | The power module temperature sensor is not working. |

| F007 | Communication error | The power module cannot communicate with the drive. |

Fixing trouble codes Sinamics Power Module 250

Correction of error F001

Error F001 on the Sinamics Power Module 250 indicates that the supply voltage applied to the module is outside the permissible range. This can be caused by a voltage that is too high or too low.

Follow these steps to resolve this error

1. Check the input voltage

- Measure the voltage at the module power terminals.

- Compare the measured voltage to the allowable range specified in the module user guide.

- The acceptable voltage range is typically 380 VAC to 500 VAC.

2. Eliminate the cause of the voltage discrepancy

The voltage is too high:

- If the voltage is too high, try to locate the source of the overvoltage.

- This could be a fault in the power supply or a fault in the module itself.

- If the source of the surge cannot be found, contact a qualified electrician.

The voltage is too low:

- If the voltage is too low, check to see if the power supply is overloaded.

- If the power supply is not overloaded, try to find the source of the voltage drop. This could be a fault in the power supply or a fault in the module itself.

- If the source of the voltage drop cannot be found, contact a qualified electrician.

3. Reset the error

Once the cause of the voltage mismatch has been resolved, reset the F001 error.

The method of resetting the error may vary depending on the module model. Typically, the reset button or a special key combination on the module control panel is used to reset the error.

Refer to the module user manual for instructions on how to reset the error.

4. Check the module operation

- After resetting the error, verify that the module is working correctly.

- If the error reappears, contact a qualified service technician.

Troubleshooting Error F002

Error F002 on the pm250 siemens indicates that the drive is using more current than the power module can supply. This can cause damage to the power module and the drive.

Follow these steps to resolve this error

1. Reduce the load on the drive

- Make sure the load on the drive does not exceed its rated capacity.

- Reduce the drive speed or torque, if possible.

- Check that the drive parameters, such as acceleration and deceleration times, are set correctly.

2. Check the input voltage

- Verify that the power supply input voltage of the power supply module is within its rated values.

- Check for voltage fluctuations in the power supply.

- Use a voltage regulator if necessary.

3. Check the power supply module

- Make sure the power supply module is properly connected to the drive.

- Check for damage to the power supply module.

- Replace the power supply module if it is damaged.

4. Check the drive

- Make sure the drive is properly connected to the power module.

- Check for damage to the drive.

- Send the drive for repair if it is damaged.

Troubleshooting error F003

Error F003: Short circuit error on Sinamics Power Module 250 indicates that a short circuit has been detected in the output circuit of the power module. This can be caused by a variety of factors such as a damaged cable, a faulty motor, or the power module itself is faulty.

Troubleshooting steps

- Turn off the power: Before starting any troubleshooting work, it is important to turn off the power to the drive and the power module. Make sure all capacitors are discharged before touching any components.

- Check the cables: Inspect all cables connected to the power supply module for damage. Make sure all connections are tight and not damaged. Replace any damaged cables.

- Check the motor: If a motor is used, disconnect it from the power supply. Turn on the power to the drive and the power module. If the F003 error disappears, the problem is with the motor. You may need to replace the motor or have it repaired.

- Check the power supply module: If the F003 error persists, the problem is probably with the power module itself. You may need to replace the power module.

Additional tips:

- You can use a multimeter to check for a short circuit in the power supply module output circuit.

- If you are unsure how to troubleshoot, contact a qualified service technician.

Troubleshooting F004

Error F004 on the Siemens Sinamics Power Module 250 indicates that the module is overheating. This can lead to serious damage to the module, so it is important to take action to resolve the problem immediately.

Steps to take to resolve F004

1. Check the ventilation

- Ensure that the power supply module vents are not blocked by dust or other objects.

- Ensure that there is sufficient free space around the power supply module for air to circulate.

- Check that the power supply fan is working. If the fan is not working, replace it.

2. Check the ambient temperature

- Make sure the ambient temperature is within the allowable range for the power supply module. The allowable temperature range is usually specified in the power supply module user manual.

- If the ambient temperature is too high, try lowering it with an air conditioner or fan.

3. Check the load on the power supply module

- Make sure the load on the power supply module does not exceed its rated capacity.

- If the load on the power supply module is too heavy, try to reduce it by disconnecting some of the loads.

4. Check the condition of the cables

- Check the cables that connect to the power supply for damage.

- Damaged cables can cause the power supply to overheat.

- Replace any damaged cables.

5. Inspect the power supply module for damage

- If you follow all of the above steps and the F004 error still appears, the power supply module might be damaged.

- In this case, you must contact a qualified service technician to repair or replace the power module.

Resolving the F005 error

Error F005 on the pm250 siemens indicates a fan failure. This can lead to overheating of the power module and other problems.

Steps you can take to resolve the F005 fault

1. Check the fan

- Turn off the power to the drive and the power module.

- Open the cover of the power supply module.

- Locate the fan.

- Check that the fan is spinning freely.

- Check for dust or other contaminants on the fan.

- If the fan is dirty, clean it.

- If the fan does not spin freely, replace it.

2. Check the power supply to the fan

- Check the voltage at the output of the fan power supply.

- If there is no voltage, replace the power supply.

3. Check the cables

- Check the cables that connect the fan to the power supply and the power module.

- Ensure that the cables are not damaged and are tightly connected.

- Replace any damaged cables.

4. Check the power supply module

- If you have completed all of the above steps and the F005 error still occurs, the power supply module itself may be defective.

- Contact a qualified service technician to repair or replace the power supply module.

Fixing error F006

Error F006 on the Siemens Sinamics Power Module 250 indicates a temperature sensor failure. This can be caused by damage to the sensor, an interrupted connection, or a fault in the sensor circuit.

Follow these steps to resolve this error

1. Check the temperature sensor

- Inspect the sensor for damage such as cracks, burns, or corrosion.

- Measure the resistance of the sensor with a multimeter. The correct resistance value should be listed in the power supply module user manual.

- If the sensor is damaged or its resistance is not within the normal range, it must be replaced with a new one.

2. Check the connection

- Check that the temperature sensor connector is tightly connected to the power supply module.

- Make sure the sensor wires are not damaged or pinched.

- Clean the connector pins if necessary.

3. Check the temperature sensor circuit on the power supply module

- This step requires detailed knowledge of electronics and experience with Siemens Sinamics power modules.

- If you do not have such knowledge and experience, it is recommended that you contact a qualified service technician.

Resolving the F007 error

Error F007 on the Sinamics Power Module 250 indicates that the power module cannot communicate with the drive. This can be caused by a variety of factors such as communication cable issues, a power module failure, or a drive failure.

Steps you can take to troubleshoot the issue

1. Check the communication cable

- Ensure that the communication cable is properly connected to the power supply and the drive.

- Inspect the cable for damage.

- Try using a different communication cable if available.

2. Check the settings

- Verify that the address of the power supply module matches the address set in the drive.

- Check the communication settings in the drive.

3. Restart the power supply and drive

- Turn off the power supply and drive.

- Wait 30 seconds.

- Turn the power supply and drive back on.

4. Reset the power supply to factory defaults

- Refer to the power module user guide to learn how to reset the power module to factory defaults.

5. Check the power supply module

- If you have completed all of the above steps and the error still occurs, there may be a fault with the power supply module.

- Contact a qualified service professional to inspect and repair the power module.

6. Check the drive

- If you have replaced the power supply module and the error still occurs, the drive may have malfunctioned.

- Contact a qualified service technician to check and repair the drive.

Preventive Maintenance

For Siemens Sinamics Power Module 250, proactive care and maintenance are paramount to ensure seamless operations and prevent costly downtime.

Measures Included in Preventive Maintenance

- Regular Inspections: Conduct routine visual inspections of the module and associated components to detect signs of wear, damage, or degradation. Pay close attention to connectors, wiring, cooling systems, and ventilation openings.

- Cleaning and Lubrication: Keep the module and surrounding areas clean and free of debris to prevent obstruction of ventilation openings and cooling systems. Lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

- Functional Testing: Perform periodic functional tests to verify the module's performance and identify any deviations from expected behavior. Test critical functions such as voltage regulation, frequency control, and overload protection.

- Software Updates: Regularly update the module's firmware and software to ensure compatibility with the latest standards and protocols. Firmware updates may include bug fixes, performance enhancements, and security patches.

- Documentation and Record-Keeping: Maintain comprehensive documentation of maintenance activities, including inspection reports, test results, and software updates. Keep detailed records of any repairs or replacements performed on the module.

Frequency of Preventive Maintenance

The frequency of preventive maintenance activities for Siemens Sinamics Power Module 250 may vary depending on factors such as operating conditions, environmental factors, and manufacturer recommendations.

Conclusion

Thorough understanding of Siemens Sinamics Power Module 250 trouble codes is indispensable for maintaining operational continuity in industrial automation settings. By promptly recognizing and addressing errors, operators and maintenance personnel can minimize downtime, optimize productivity, and protect valuable assets. Additionally, implementing preventive maintenance measures ensures long-term reliability and efficiency. As technology continues to evolve, staying vigilant and proactive in error detection and correction remains paramount. With proactive maintenance and a keen understanding of fault codes, businesses can ensure seamless operations and stay ahead in the ever-changing landscape of industrial automation.