Sinamics Power Module 340 fault codes

19.09.2024

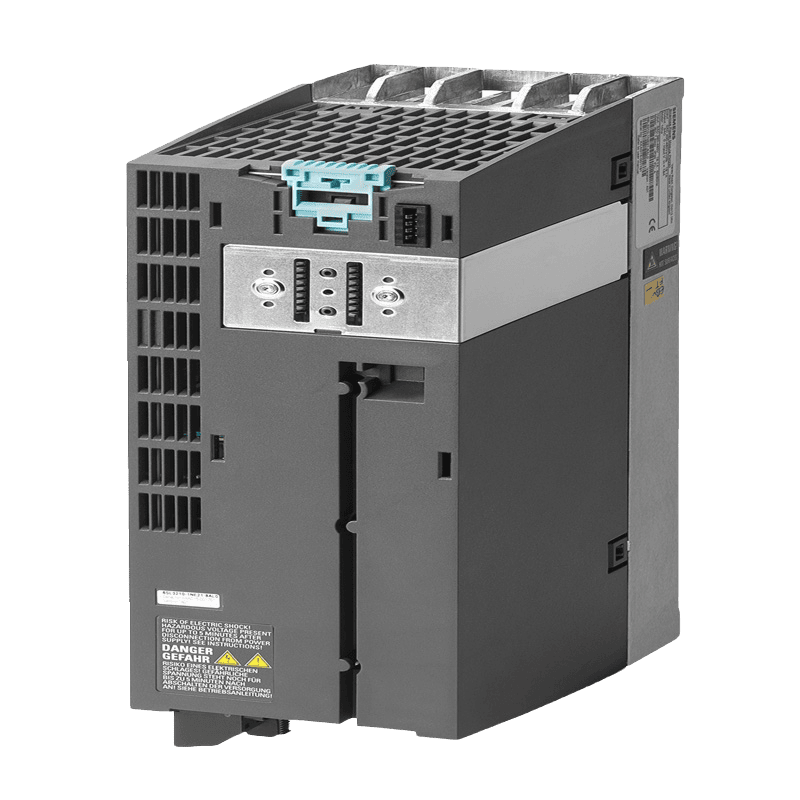

A crucial component of Siemens' Sinamics drive system, which is frequently utilized in industrial automation to deliver dependable power conversion and motor control, is the Siemens sinamics power module 340 (PM340). The PM340 is engineered to meet the needs of a diverse variety of demanding applications, such as fans, pumps, conveyor systems, and more. Its excellent performance guarantees seamless and effective operation even in the most demanding industrial settings.

This power module is known for its robust design and ability to handle complex motor control tasks. It manages high-power outputs while maintaining precise control over motor speed and torque. In addition, it integrates advanced diagnostics, which allow operators to monitor system performance and quickly address any issues that may arise. These diagnostic features, such as fault codes, play a critical role in identifying, troubleshooting, and preventing system malfunctions, making the siemens power module 340 a reliable choice for industrial operations.

Understanding the fault codes generated by the PM340 is crucial for maintaining uninterrupted operation, as these codes provide insight into potential issues, helping to minimize downtime and ensure the longevity of the equipment.

Why Fault Codes Matter in Sinamics Power Module 340

Fault codes in the Sinamics Power Module 340 are vital for maintaining operational efficiency and ensuring the reliability of the drive system. As an industrial automation expert, understanding these fault codes is crucial because they serve as the first line of defense against potential system failures. When the PM340 encounters an issue—whether it's related to power, motor overload, or an environmental condition like temperature—fault codes are automatically generated to notify operators of the specific problem.

These codes are more than just error messages; they provide detailed insights into the nature of the fault, enabling faster diagnostics and resolution. In industrial settings where downtime can be extremely costly, the ability to quickly identify and rectify issues through fault codes significantly reduces operational interruptions. Moreover, the fault codes in the siemens power module 340 often highlight underlying issues that may not be immediately apparent, allowing maintenance teams to proactively address problems before they escalate into more serious malfunctions.

Fault Codes in Sinamics PM340

When working with the Sinamics Power Module 340, it is important to understand the various fault codes that may occur during operation. These trouble codes help you diagnose and troubleshoot problems effectively. Below is a list of common fault codes for the PM340 along with their causes and recommended solutions:

| Fault Code | Cause | Solution |

| F30040 | 24V power supply failure. The 16V threshold has fallen below more than 3 ms. | Check the 24V power supply and ensure it is stable. Replace if necessary. |

| F30045 | Low supply voltage. | Verify the supply voltage and ensure it meets the required specifications. |

| F30885 | No communication with one of the system’s Drive-Cliq Power Modules, although it is configured. | Check the Drive-Cliq connections and ensure all modules are properly connected and configured. |

| F31115 | Signal amplitude error A or B. | Inspect the signal connections and ensure there are no loose or damaged wires. |

| F31116 | A + B signal monitoring amplitude error. | Verify the signal integrity and check for any interference or noise in the signal lines. |

| F30021 | Overtemperature in the power module. | Ensure adequate cooling and ventilation. Check for any obstructions in the airflow. |

| F30022 | Overcurrent in the power module. | Inspect the load and connections for any short circuits or overload conditions. |

| F30023 | Undervoltage in the DC link. | Check the DC link voltage and ensure it is within the specified range. |

| F30024 | Overvoltage in the DC link. | Verify the DC link voltage and ensure it does not exceed the specified limits. |

| F30025 | Ground fault detected. | Inspect the insulation and connections for any ground faults. |

| F30026 | Motor overtemperature. | Check the motor cooling system and ensure it is functioning properly. |

| F30027 | Encoder error. | Verify the encoder connections and ensure it is properly aligned and functioning. |

| F30028 | Brake chopper fault. | Inspect the brake chopper and ensure it is operating correctly. |

| F30029 | Power module hardware fault. | Perform a hardware diagnostic and replace any faulty components. |

| F30030 | Internal communication error. | Check the internal communication connections and ensure all modules are properly connected. |

Advanced Troubleshooting Techniques

- Systematic Fault Isolation: Begin by isolating the fault to a specific module or component. This can be achieved by systematically checking each part of the system, starting from the power supply and moving towards the motor.

- Signal Tracing: Use oscilloscopes and signal analyzers to trace and monitor signals within the system. This helps in identifying anomalies in signal patterns that could indicate faults.

- Thermal Imaging: Use thermal imaging cameras to identify parts that are overheating. Overheating is a common cause of faults and can be identified early with thermal imaging.

- Load Testing: Perform load tests to ensure the system can handle the required operational load without faults. This helps in identifying issues related to overcurrent or under voltage conditions.

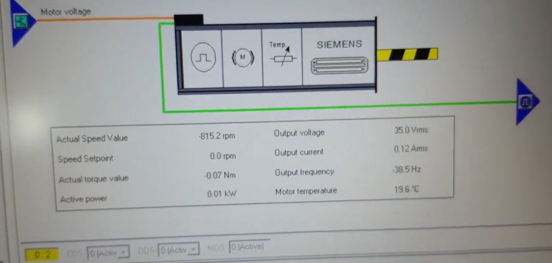

The Role of Software Tools in Fault Diagnosis

Software tools are essential for troubleshooting PM340 issues. These solutions increase the efficiency of defect diagnosis by offering real-time data and in-depth insights:

- Siemens Drive ES: This software allows for comprehensive monitoring and diagnostics of Siemens sinamics drive. It offers up-to-date information on operating parameters, fault codes, and drive status.

- TIA Portal: A unified engineering environment is created by integrating all automation devices through the Totally Integrated Automation (TIA) Portal. It offers advanced diagnostic tools and fault analysis features.

- Sinamics Startdrive: This tool is specifically designed for commissioning and diagnosing Sinamics drives. It offers intuitive interfaces and detailed fault logs to aid in troubleshooting.

Preventing Common Sinamics Power Module 340 Faults

Preventing common faults in the sinamics pm340 involves a combination of regular maintenance, proper installation, and careful monitoring.

1. Regular Maintenance

- Scheduled Inspections: Regularly inspect the power module for any signs of wear and tear. Look for loose connections, damaged cables, and signs of overheating.

- Cleaning: Ensure the module is free from dust and debris. Dust can cause overheating and short circuits. Use a dry, soft brush or compressed air to clean the module.

- Firmware Updates: Keep the firmware updated to the latest version. Firmware updates often include fixes for known issues and improvements in performance.

2. Proper Installation

- Correct Wiring: Ensure all wiring is done according to the manufacturer’s specifications. Incorrect wiring can lead to faults and even damage the module.

- Adequate Ventilation: Install the module in a well-ventilated area to prevent overheating. Ensure there is enough space around the module for air circulation.

- Environmental Conditions: Install the module in an environment that is within the specified temperature and humidity range. Extreme conditions can affect the performance and longevity of the module.

3. Monitoring and Diagnostics

- Use Diagnostic Tools: Utilize the diagnostic tools provided by Siemens to monitor the health of the power module. These tools can help you identify potential issues before they become serious problems.

- Error Codes: Familiarize yourself with common error codes and their meanings. This will help you quickly diagnose and address issues as they arise3.

- Load Monitoring: Monitor the load on the power module to ensure it is within the specified limits. Overloading can cause faults and reduce the lifespan of the module.

4. Preventive Measures

- Surge Protection: Use surge protectors to protect the module from voltage spikes. Voltage spikes can cause significant damage to electronic components.

- Regular Testing: Perform regular tests to ensure the module is functioning correctly. This includes checking the output voltage and current to ensure they are within the specified range.

- Training: Ensure that all personnel who operate or maintain the power module are properly trained. Proper training can prevent many common faults caused by human error.

How Regular Maintenance Helps Prevent Faults

Regular maintenance is essential for the longevity and reliability of the Siemens sinamics power module 340. Here’s how it helps:

- Early Fault Detection: Frequent maintenance enables the early identification of any problems before they develop into significant malfunctions. This includes inspecting worn-out parts, loose connections, and software updates.

- Optimized Performance: Maintenance ensures that the sinamics pm340 operates at optimal performance levels. This includes cleaning filters, checking cooling systems, and ensuring proper ventilation.

- Extended Lifespan: Consistent maintenance extends the lifespan of the pm340 siemens by preventing premature wear and tear. This reduces the likelihood of unexpected failures and costly downtime.

By understanding and implementing these advanced troubleshooting techniques, leveraging software tools, preventing common faults, and maintaining regular maintenance schedules, you can ensure the reliable operation of the Sinamics Power Module 340. This proactive approach not only minimizes downtime but also enhances the overall efficiency of your industrial automation systems.

Conclusion

Understanding and managing fault codes in the Sinamics Power Module 340 is crucial for maintaining the efficiency and reliability of industrial automation systems.You may drastically lower the likelihood of errors and guarantee fault-free operations by using sophisticated troubleshooting methods, utilizing strong software tools, and following precautionary steps. Regular maintenance plays a pivotal role in early fault detection and optimizing the performance of the pm340 siemens, ultimately extending its lifespan and minimizing downtime.

By adopting a proactive approach to fault management, industries can improve their operational efficiency, prevent costly breakdowns, and maintain uninterrupted performance from their Sinamics Power Module 340.

Selection of Siemens SINAMICS power modules at Eltra Trade! We offer competitive prices and ensure fast, worldwide delivery, so you receive your products quickly and efficiently. As your trusted partner, we are dedicated to helping you find the perfect power modules to suit your needs. Our knowledgeable team is always ready to provide expert advice and support. Visit our website today to explore our extensive range and see why we are the preferred choice for industrial control solutions.