Rotary potentiometer wih fixing flange screw holes (diam. 30mm). Resistive value 10k ohm/1 turn.

Rotary potentiometer wih fixing flange screw holes (diam. 30mm). Resistive value 10k ohm/1 turn.

Rotary potentiometer wih fixing flange screw holes (diam. 30mm). Resistive value 10k ohm/1 turn.

Rotary potentiometer wih fixing flange screw holes (diam. 30mm). Resistive value 10k ohm/3 turn.

Rotary potentiometer wih fixing flange screw holes (diam. 30mm). Resistive value 5k ohm/10 turn.

Rotary potentiometer wih fixing flange screw holes (diam. 30mm). Resistive value 5k ohm/1 turn.

Rotary potentiometer wih fixing flange screw holes (diam. 30mm). Resistive value 5k ohm/3 turn.

Rotary potentiometer with fixing flange screw holes

Rotary potentiometer wih fixing flange screw holes (diam. 30mm) with cogged shaft. Resistive value 1k ohm/1 turn.

Rotary potentiometer wih fixing flange screw holes (diam. 30mm) with cogged shaft. Resistive value 10k ohm/1 turn.

Rotary potentiometer wih fixing flange screw holes (diam. 30mm) with cogged shaft.

Rotary potentiometer wih fixing flange screw holes (diam. 30mm) with cogged shaft. Resistive value 5k ohm/3 turn.

1 lt, 360 bar

360 Bar, 10 lt

Absolute linear potentiometer without internal rod.

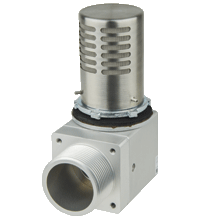

- Maximum enclosure size 450 ft3 (12.7 m3)

- Pressure relief vent with flow and pressure monitoring at the exhaust

- Universal mounting in any orientation

- 6000 Control Unit supports 2 vents

- Different vents for different applications

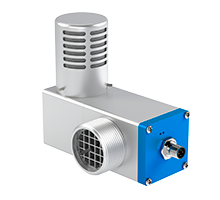

Purge&Pressurization

Purge&Pressurization

- One design, three flow rate variants to support your design requirements

- Anodized aluminum with an optional stainless steel cap

- Universal mounting

Purge&Pressurization

Purge&Pressurization

- A selection of vents for specific applications

- Intrinsically safe operation

- Continuous flow vents for precise flow rates for dilution applications

- Continuous flow outputs for dilution, purging, and pressurization

- Low leakage rate vents for air or inert gas conversation

- High flow rate vents for fast, large enclosure systems

- Universal mounting in any orientation including most of the unit inside the enclosure

- Maximum enclosure size 12.75 cu.meters (450 cu.ft.)

- ATEX/IECEx, Zone 1/21 certified for ""pyb"" and ""pxb""

- Up to SIL 2 acc. to IEC 61508

- A selection of vents for specific applications

- Intrinsically safe operation

- Continuous flow vents for precise flow rates for dilution applications

- Continuous flow outputs for dilution, purging, and pressurization

- Low leakage rate vents for air or inert gas conversation

- High flow rate vents for fast, large enclosure systems

- Universal mounting in any orientation including most of the unit inside the enclosure

- Low cost, universal mounting, easy to use

- Not gravity dependent

- Various enclosure protection vents for different applications

- Rugged, corrosion-resistant housing

- Mechanical with no cables

- Global third-party approvals for Class I, II, Div. 2 and Zone 2/22

- Must be used in conjunction with a 7500-01-AA* or 7500-MTD-* purge and pressurization control unit

- Low cost, universal mounting, easy to use

- Not gravity dependent

- Various enclosure protection vents for different applications

- Rugged, corrosion-resistant housing

- Mechanical with no cables

- Global third-party approvals for Class I, II, Div. 2 and Zone 2/22

- Must be used in conjunction with a 7500-01-AA* or 7500-MTD-* purge and pressurization control unit

- Low cost, universal mounting, easy to use

- Not gravity dependent

- Various enclosure protection vents for different applications

- Rugged, corrosion-resistant housing

- Mechanical with no cables

- Global third-party approvals for Class I, II, Div. 2 and Zone 2/22

- Must be used in conjunction with a 7500-01-AA* or 7500-MTD-* purge and pressurization control unit

- Low cost, universal mounting, easy to use

- Not gravity dependent

- Various enclosure protection vents for different applications

- Rugged, corrosion-resistant housing

- Mechanical with no cables

- Global third-party approvals for Class I, II, Div. 2 and Zone 2/22