ABB ACS800 Drives & Modules

- ACS800-01 Wall-Mounted Single Drives

- ACS800-02 Free-Standing Drives

- ACS800-04 Single Drive Modules

- ACS800-07 Cabinet-built Single Drives

- ACS800-104 | ACS800-107 Inverter Modules

- ACS800-17 | ACS800-14 Regenerative Drives

- ACS800-204 | ACS800-207 Supply Modules

- ACS800-37 | ACS800-31 | 38 Low Harmonic Drives

- ACS800-U Drives (US)

- ACS800 Аccessories

PREVENTIVE MAINTENANCE KIT

IN STOCK!!!

40/085/56 4700 μF -10 n +30% 400VDC

EL. CAP. ALS30C1023NP 64624920

IN STOCK!!!

40/085/56 3300 μF -10 n +30% 400VDC

IN STOCK!!!

CDP 312R Control panel for ACS800

IN STOCK!!!

230VAC, 345W, 50 Hz, 0,88 A, 2050 rpm

Cooling fan IP54

- High performance

- High reliability

- Wide operating temperature range:

- Easy installation

Fan unitA BB W2E200

- Power - 200 W

- EFFICIENCY - 65 %.

- Protection class IP54

- Simple design

- Wide operating temperature range

- Durability

D4E225-CC01-56; LONG-LIFE FAN, CENTRIFUGAL

| Type | FAN, AXIAL |

| Weight | 0.1 kg |

| Type | FF450R12KE4 IGBT-MODULE 3 PCS |

| Weight | 1.14 kg |

| Type | SPAREPART KIT MAIN CIRCUIT BOAR |

| Weight | 0.4 kg |

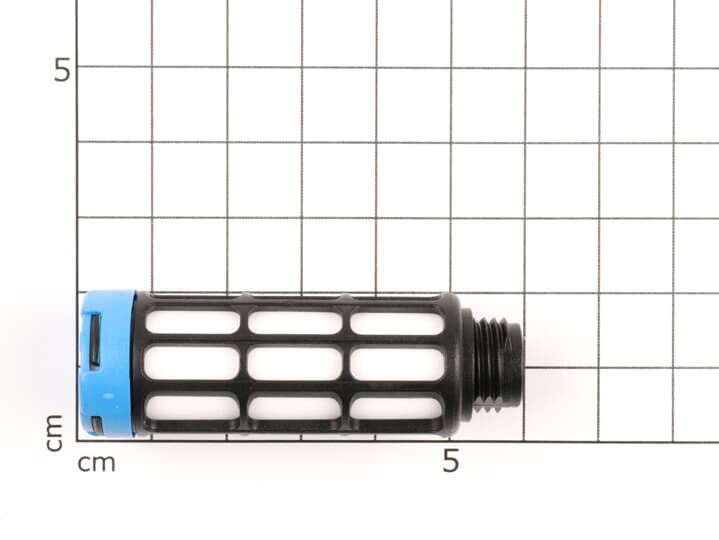

Air filter, G1/4 in.

- 24 V

- 19 W

- 24VDC

- 19W

- IP20

| Type | Inverter |

| Weight | 38 kg |

| Type | Inverter |

| Weight | 130 kg |

ACS800-14-0260-3-0320-5 (ALCL capac PM6Y814ALCL135)

Type: PREV.MAINT. KIT, 6 YEARSv

Weight: 0.11 kg

| Type | PREV.MAINT. KIT, 6 YEARS |

| Weight | 2.1 kg |

ACS800-17-0320-3-0400-5 (ALCL capac PM6Y837ALCL145)

Type: PREV.MAINT. KIT, 6 YEARSv

Weight: 0.11 kg

ACS800-17-0770-3-1140-5 ALCL capac PM6Y817ALCL255

Type: PREV.MAINT. KIT, 6 YEARSv

Weight:0.11 kg

ACS800-17-2780-3310-7 (ALCL capacit PM6Y837ALCL3X257)

Type: PREV.MAINT. KIT, 6 YEARSv

Weight: 49.95 kg

ABB ACS800-207-2490-3-2960-5 ALCL capa PM6Y800ISULCL3X255

Type: PREV.MAINT. KIT, 6 YEARSv

Weight: 51.6 kg

| Type | PREV.MAINT. KIT, 6 YEARS |

| Weight | 7 kg |

ACS800-37-0060-3-0540-7 IF OPTION+D PM3Y837FAN2BCR6R8

Type: PREV.MAINT. KIT, 6 YEARSv

Weight: 1 kg

| Type | FILTER (AIR) |

| Weight | 0.4 kg |

| Type | ACS800-104LC R8I |

| Weight | 0.56 kg |

| Type | PROTECTION BOARD |

| Weight | 0.18 kg |

| Type | ASTO-kit |

| Weight | 0.811 kg |

| Type | CAPACITOR |

| Weight | 1.89 kg |

| Type | QUICK CONNECTOR |

| Weight | 0.016 kg |

| Type | Installation accessories |

| Weight | 0.216 kg |

Modern automation of technological processes is based on the use of a frequency-controlled electric drive. The scope of ABB's interests includes the creation of frequency converters for solving problems associated with the use of asynchronous electric motors. ABB frequency drives are distinguished by a number of advantages that combine an affordable price, high quality, and great functionality.

ABB ACS800 Drive models provide new advanced methods for controlling inverters using semiconductor elements: IGBT, GTO, IGCT, and various types of PWM. An example can be industrial drives in the design, which use an active rectifier on IGBT transistors, it serves to regenerate electrical energy necessary in the work of converting the voltage of a 3-phase network into voltage.

The main trend in the development of ABB inverter is to create equipment that can successfully suppress higher harmonics - software PWM or PWM with tracking, or PWM combined with pulse amplitude modulation. When creating ABB frequency converters, attention is paid to improving the output control.

ACS800 series frequency converters are designed for industrial use. They are produced both in the form of housing drives with a complete set of necessary functional devices in their design and in the form of modules. They are versatile, flexible AC drives that can be configured exactly to meet the requirements of specific industrial applications.

Distinctive features:

- Intuitive control panel and software tools.

- Advanced motor torque direct control algorithm for precise control in closed and open-loop control systems.

- Simplified parameterization due to integrated safety functions.

- Ability to connect to automation networks using the main data transfer protocols.

- Easy configuration and commissioning thanks to the removable memory block.

- Power consumption optimization functions and the ability to monitor it.

- Built-in PID process controllers.

ABB ACS800 frequency converters are used in situations where several drives have to work within a single technological process, controlling a group of motors. The common rectifier in multi-component drives provides common safety and control functions. The shafts of individual motors may be rigidly coupled (for example, in a paper machine) or not connected to each other (for example, in centrifuges for sugar production). This sets a separate speed control algorithm for each drive module to reduce overall power consumption. Scope: paper machines, rolling mills, drilling rigs, press-forging equipment, quarry equipment.

Industrial drives (frequency converters) ABB ACS800 drive are designed for industrial use in industries such as metallurgy and metalworking, mining and cement industry, power industry, chemical and oil and gas industry, pulp and paper production. Industrial frequency converters ACS800 are produced by ABB both in the form of case drives, which have in their design a complete set of necessary functional devices (line chokes, EMC filters, brake choppers, motor filters, etc.) and in the form of modules designed for embedding in manufacturing and machine tools by OEMs and system integrators.

Fully featured ABB frequency converters and modules - cover a wide power range from 0.55 to 5600 kW and voltages from 220 to 690 V.

ACS800 drives are designed for operating currents and operating conditions specific to heavy-duty industrial equipment requiring high overload capacity and increased reliability. The "heart" of this series of drives is a motor control algorithm called DTC (Direct Torque Control) - direct torque control, which provides high performance and provides significant advantages over traditional vector control: accurate static and dynamic control of speed and torque, large starting torque, eliminating the possibility of false alarms of the built-in protection of the drive and the motor, a significantly larger allowable length of the motor cable without the use of additional protective motor filters.

Another feature of this series of ABB frequency converters is the ability to use additional software in the drive, designed to solve a number of applied tasks, for example, control programs for a crane, centrifuge, pump group, winding equipment, etc. There is a total of 16 such application programs to choose from. An additional opportunity to flexibly configure the drive for the current task is provided by the presence of a programmable logic controller for 15 functional blocks in its composition.

Possibilities for embedding - frequency converters ABB series ACS800 - in any automation systems and process control systems are provided by a wide range of optional modules for communication, sensor connection, and I/O expansion. ABB ACS800 frequency converters support PROFIBUS, DeviceNet, CANopen, ControlNet, Modbus-RTU, Ethernet, LonWorks, etc. communication protocols.

Types of frequency converters ABB

ABB frequency converters are divided into three main large groups

- Drives used in mechanical engineering - a series of components ACS55 and ACS150; ACS355; ACSM Recommended for equipment with a continuously variable speed control of the entire process.

- Frequency converters of standard type for various industries ACS310, ACS550, ACH The devices are most popular for controlling the speed of pumps, conveyors, or fans, for equipment that needs constant torque.

- Industrial drives - ACS800 (multidrive), ACS850, and universally compatible single ACS series of industrial multi-function frequency converters Typically used in mining, oil and gas, electric power, metallurgy, metalworking, and other critical industries.

If you want to find more information about ABB ACS 800 industrial drives you should read ABB ACS800 user manual.