Choose a subcategory:

Show all categories

PM571-ETH-V14x 64kB 24VDC

PROFIBUS, CI854AK01 DATA INTERFACE

Communication Module, 2x serial

Software License, AB, 1.x-2.x Standard DM201-TOOL-UPGR AB 2.x StdUpgr lic (1SAS010001R0102)

CPU V2, memory 512 kB, 24 V DC

CPU Terminal Base AC500, slots: 1

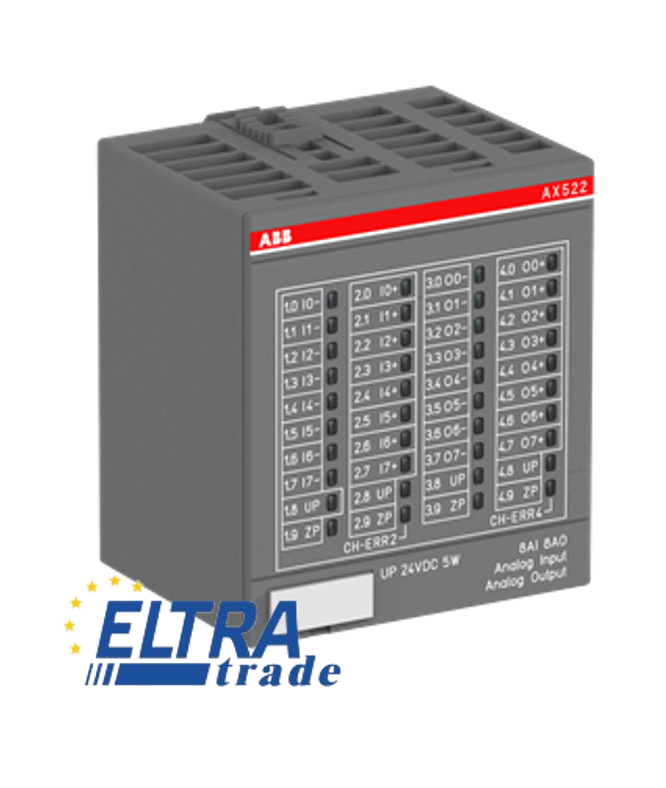

I/O Terminal Unit, 24 V DC, spring terminals

AC500 Key features

The ABB AC500 PLC (Programmable Logic Controller) system is a versatile and powerful control solution suitable for various applications in various industries. It offers a range of key features that make it a popular choice among engineers and automation professionals.

- One of the key features of the AC500 PLC system is its modular design. The PLC system consists of a range of modules that can be easily configured and customized to meet the specific needs of a particular application. This allows users to expand the system as their requirements change easily.

- Another key feature of the AC500 PLC system is its high-performance processor. The PLC system is equipped with a powerful processor that can handle large amounts of data and perform complex calculations quickly and efficiently. This makes it well-suited for use in high-speed and high-precision applications.

- The AC500 PLC system offers various communication options, including Ethernet, serial, and Fieldbus interfaces. This allows users to easily integrate the PLC into their existing automation system and communicate with other devices using a variety of industrial protocols.

- The AC500 PLC system also offers a wide range of safety features, such as built-in safety functions, safety-rated inputs and outputs, and safety-rated communication modules. This makes it well-suited for use in safety-critical applications.

AC500 Communication modules

The ABB AC500 PLC system offers a wide range of communication modules that provide connectivity between the PLC and other devices, such as HMI, SCADA, and other PLCs. These modules allow users to integrate the PLC into their automation system easily and to communicate with other devices using a variety of industrial protocols.

- One of the key communication modules offered by ABB is the AC500-eCo. This module provides an Ethernet-based communication interface for the PLC and supports a wide range of industrial protocols such as Modbus TCP/IP, EtherNet/IP, and Profinet. The eCo module also supports the OPC UA protocol, which allows for easy integration with other systems and devices.

- Another popular communication module offered by ABB is the AC500-S500. This module provides a serial communication interface for the PLC and supports a wide range of industrial protocols such as Modbus RTU, Profibus DP, and DF1. The S500 module also supports the Sercos III protocol, which is commonly used in motion control applications.

- ABB also offers a range of specialty communication modules, such as the AC500-XC100. This module is designed for use in extreme temperatures and harsh environments and supports a wide range of industrial protocols such as Modbus RTU, Profibus DP, and EtherCAT.

How to program ABB PLC AC500?

Programming an ABB PLC ac500 requires programming software like ABB's Freelance Control Builder or AC500 PLC programming software. These software tools provide a user-friendly interface for creating and editing PLC programs and allow users to communicate easily with the PLC via a USB or Ethernet connection.

Before starting to program the ABB PLC ac500, it is important to ensure that the PLC is properly connected to the computer and that the programming software is installed and configured correctly. Once this is done, the following steps can be followed to program the PLC:

- Start the programming software and create a new project by selecting the "New" option from the File menu.

- Create a new program by selecting the "New" option from the Program menu.

- Use the programming software's drag-and-drop interface to add instructions and functions to the program, such as timers, counters, and logic operations.

- Configure the PLC's inputs and outputs by assigning them to specific instructions and functions within the program.

- Test the program by simulating its operation using the programming software's built-in simulation tools.

- Once the program works correctly in simulation mode, download it to the PLC by selecting the "Download" option from the Program menu.

- After the program is downloaded, test the PLC's operation in real-time to ensure it works as expected.

Programming PLCs requires a certain level of knowledge about the device and its functions. If you're not familiar with it, it may be best to consult the manual or seek assistance from a trained professional.

The steps include:

- Creating a new project.

- Creating a new program.

- Adding instructions and functions.

- Configuring inputs and outputs.

- Testing the program in simulation mode and downloading it to the PLC.

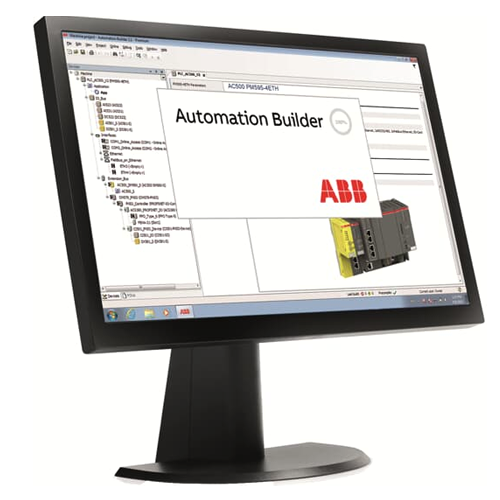

ABB PLC programming software

Programming an ABB Programmable Logic Controller requires a specialized software tool. ABB offers a range of programming software options that provide a user-friendly interface for creating and editing PLC programs and allow users to communicate easily with the PLC via a USB or Ethernet connection.

One of ABB's most popular programming software options is Freelance Control Builder. This software is a powerful, easy-to-use programming tool suitable for a wide range of control applications. It provides a comprehensive set of functions and features, including a graphical programming language, simulation tools, and support for a wide range of industrial protocols.

Another popular programming software option offered by ABB is AC500 PLC programming software. This software is designed specifically for ABB's AC500 PLC range and provides a user-friendly interface for creating and editing PLC programs. It also supports industrial protocols and includes simulation tools for testing and debugging PLC programs.

ABB also offers a range of other programming software options, such as the AC500-S Safety PLC programming software, designed for use in safety-critical applications, and the AC500-XC100 programming software, designed for use in extreme temperatures and harsh environments.

In summary, ABB offers a range of programming software options for its PLCs, such as Freelance Control Builder, AC500 PLC programming software, AC500-S Safety PLC programming software, and AC500-XC100 programming software. These software tools provide a user-friendly interface for creating and editing PLC programs and allow users to communicate easily with the PLC via a USB or Ethernet connection. They also support industrial protocols and include simulation tools for testing and debugging PLC programs. Some software options are designed for specific use cases, such as safety-critical applications or extreme environments.