Balluff Inductive sensors

IN STOCK!!!

Balluff BES 516-110D (BES02MJ) Inductive sensor

- Operating principle: inductive

- Type: non-contact

- Operates at a distance of 1.5-6.0 mm

IN STOCK!

BES038L

High-temperature (100°C) inductive proximity sensor in a 7.9mm stainless steel housing with PNP NO output and M12 connector.

IN STOCK!!!

- Order Code: BHS002Y

- Operating distance 1.2 mm

- Housing: D7,9

IN STOCK!!!

- Cylindrical Inductive Sensors

- Sensing distance: up to 2 mm

- Order Code: BHS001L

IN STOCK!!!

- BES 516-300-S249-S4-D

- Order Code: BHS002Y

- Operating distance Sn 1.5 mm

IN STOCK!!!

Baluff Inductive Sensor BES series

- Dimensions: Ø 8 x 50 mm

- Action range: 4 mm

- Switching frequency: 1500 Hz

2.2 mm range, PA 12 material, IP67

Switching point - 1000 Hz

Balluff is one of the leading manufacturers of inductive sensors. The company offers you a wide range of industry automation and control solutions. Their solutions are known for their high accuracy and reliability, which makes them suitable for a variety of applications in various industries.

The Balluff inductive sensor is a parametric converter. Its operating principle is based on changing the inductance (mutual inductance) of the core with the winding. The change in inductance, in turn, occurs due to a change in resistance in the magnetic circuit of the sensor, which includes the core.

Simply put, an inductive sensor is a contactless switch. They got their name from the operating principle of non-contact metal sensing. The sensor has a sensitive element (inductance coil) with a magnetic circuit open towards the working surface of the sensor.

How Balluff Inductive Sensors Work

Balluff sensor technology is based on the principle of electromagnetic induction. Inside the sensor is a coil through which an alternating electric current passes, creating an alternating magnetic field. This magnetic field spreads around the sensor and interacts with metal objects in its action area. When a metal object enters the location of this magnetic field, an electric current is induced in it, which leads to a change in the characteristics of the sensor's magnetic field.

This process causes a change in the amplitude or phase of the signal in the sensor circuit, which is recorded by the built-in electronics. When the system detects this change, it generates a signal that can be used to control other devices or inform the operator of the presence of an object. The sensors can differentiate objects by their material type and distance to them, which allows for precise process control.

Balluff industrial inductive sensors have many applications in automation, including position control, rotational speed measurement, and detection of the presence of objects. Their main advantage is contactless operation, which ensures a long service life of the device since there is no mechanical wear. In addition, these sensors are resistant to dirt, vibration, and extreme environmental conditions, making them ideal for industrial applications.

Types of Balluff Inductive Sensors

Balluff manufactures a wide range of inductive sensors that you can use to detect metal objects without making direct contact with them. Balluff inductive sensors are known for their high reliability and accuracy. They can operate in a variety of conditions, including high temperatures, vibrations, and aggressive environments. The company offers a variety of models, including compact options for tight spaces and sensors with advanced functionality, such as a long detection range.

Standard inductive sensors

These sensors are designed for non-contact detection of metal objects within a specified range. They provide high accuracy and reliability in various industrial environments and are resistant to dirt and mechanical impacts.

Long-range inductive sensors

Such devices have an increased detection range, which allows them to be used in applications that require a greater distance between the sensor and the object. These inductive position sensors are especially useful in environments where physical contact with the object must be avoided.

Cylindrical inductive sensors

Sensors in a cylindrical housing are one of the most popular and versatile types. They are available in different sizes and can be integrated into various devices for control and automation tasks.

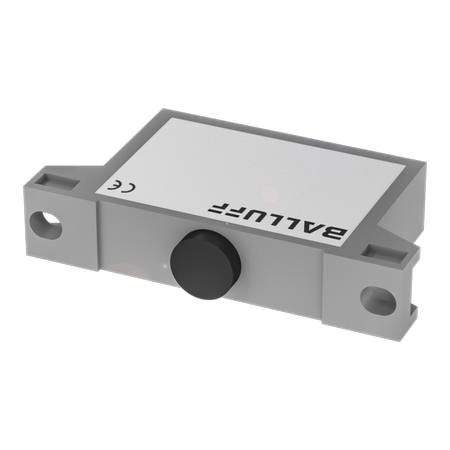

Rectangular inductive proximity sensors

These sensors have a rectangular housing and are often used in situations where installation in a limited space is required. Such inductive proximity sensors provide stable operation and reliability, especially in difficult operating conditions.

Special inductive sensors

This type includes sensors for specialized applications, such as high-temperature environments, aggressive chemical environments, or sensors with enhanced protection against external influences. They are designed to operate in extreme conditions where standard sensors cannot function.

Installation and Configuration

Installing Balluff inductive sensors requires you to select a suitable mounting location, keeping in mind that the sensors must be installed at a sufficient distance from other metal objects to avoid false alarms. The sensor housing must be securely fastened using fasteners that are appropriate for the sensor type and operating conditions. You should also consider environmental conditions such as temperature and pollution levels to select the optimal installation location and minimize possible interference. You should also consider the recommended operating distance of the sensor to the object to ensure accurate operation.

Once you have installed the sensor, it is important to connect it correctly to the control system. Balluff sensors are usually equipped with standard M12 connectors or terminal blocks that ensure a reliable electrical connection. When connecting, pay attention to the polarity and compliance with the rated supply voltage to avoid damaging the sensor. It is also important to ensure that the signal wires are correctly connected to the controller or display device for the correct operation of the sensor.

As for tuning, this includes adjusting the sensitivity and operating parameters to achieve optimal performance. Typically, you can do this with adjustment elements such as potentiometers that allow you to adjust the sensor's response distance. Some models may support digital adjustment via software interfaces or control panels. After adjustment, it is recommended to test the sensor in a duty cycle to ensure that it operates stably and does not generate false alarms. This also helps to tune the sensor to work in specific operating conditions.

Once the installation and adjustment are complete, you need to test the operation of the inductive sensor. This includes checking the sensor's response to approaching metal objects, checking the correct operation of the output signals, and checking for interference and possible false alarms. It is also recommended to test in conditions as close as possible to working conditions to ensure that the sensor operates correctly in real operating conditions.

Why Choose Balluff for Inductive Sensing?

If you choose Balluff inductive sensing technology, you can be sure that the company provides high reliability and durability of equipment, which is especially important in difficult industrial conditions. Balluff inductive sensors are popular among consumers for their resistance to wear, vibration, chemical influences, and extreme temperatures. Thanks to the use of high-quality materials and advanced technologies, sensors of this brand withstand harsh operating conditions, which ensures a long service life and minimal downtime of your equipment. This is the ideal choice for you if your industrial enterprise strives to increase productivity and reduce operating costs.

Another reason to choose Balluff metal detection sensors is the high accuracy and stability of measurements, which are guaranteed even in difficult conditions. Balluff inductive sensors provide accurate positioning of metal objects with minimal delay and high repeatability of results. This is especially important in automated processes where an instant and reliable response to changing conditions is required. Balluff also offers a wide range of sensors, including models with different operating ranges, shapes, and sizes, allowing you to find the optimal solution for any task, from standard to specialized.

In addition, Balluff offers excellent technical support and advice at all stages of working with their products. Regardless of the complexity of the task, Balluff specialists are ready to help with the selection, installation, and configuration of sensors, providing a high level of service. The availability of detailed documentation and training materials also facilitates the process of integrating sensors into production processes. Thus, by choosing Balluff, you get not only high-quality equipment but also professional support, which contributes to the successful implementation of projects and increased efficiency.