Baumer Parts in Stock

IN STOCK!!!

- art. 11070721

- TDP 0,2 LT-4 B10 55

- Have high signal quality

IN STOCK!!!

Connector

- NAC 29H 10-pin Mil Spec Mating Connector

- necessary for electrical connection to the control system

- accessories for operation

IN STOCK!!!

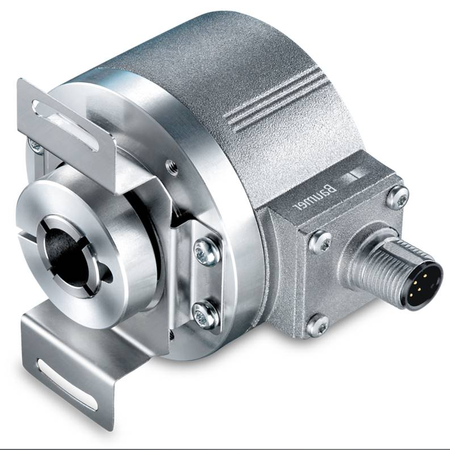

Incremental encoder

- Voltage supply: 4.75...30 VDC

- Operating temperature: -40...+100 °C

- Weight: 300 g

IN STOCK!!!

Incremental encoder

- Voltage supply: 4.75...30 VDC

- Operating temperature: -40...+100 °C

- Weight: 300 g

IN STOCK!!!

Incremental encoder

- Case Diameter: 58 mm

- Ambient temperature: -40...+ 100 С

- Maximum speed: 12,000 rpm

IN STOCK!!!

Handheld Programming Tool (for Programmable Encoders HS35P, EIL580P, ITD2P)

- Status: LED

- Backlit display

- Menu: based intuitive programming

IN STOCK!!!

Incremental optical encoder

- Diameter: 80 mm

- Increased accuracy

- Suitable for all standard industrial applications

IN STOCK!!!

Connection cable HS35P with connector MIL, 10-pin / connector D-SUB, 0.5 m

- Accessory for Baumer 11076547

- Designed for heavy duty operations

- Used as a feedback element for motor control via an inverter

IN STOCK!!!

Cover

- Protective covering

- for NEMA 56C (4.5) and fan cover

- accessory for Baumer 11076547

IN STOCK!!!

Tether arm T3

- Accessory for Baumer 11076547

- Prevents overload of the bearing force

- Flexible mounting point orientation

- Adjustable length

- For bolt 1/4”

The Baumer Group is one of the world's guiding producers of actuators, metering tools and components for automated machine vision processing. The family business currently employs over 2,000 people in 19 countries.

Baumer's history began in 1952 when Herbert Baumer, a alumnus mechanic from the ETH University in Zurich, founded Baumer Electric. The firm particularized in accuracy mechanics and originally produced microswitches. My-Com sensors are still produced to this day, and it was their production that ensured the company's success all over the world.

Already by the beginning of the 90s, the company, in addition to mechanical switches, produced non-contact sensors and encoders. The manufactured products were used in designing, aircraft andactually in the space branches.

From year to year, more and more new representative offices of the company were opened in Europe and the USA. In 1991, all divisions of the company were merged into Baumer Holding AG.

Throughout its history, the Baumer Group has been heavily involved in innovation. Engineers, technologists, designers work together every day, constantly improving Baumer products and solutions. The main focus has always been and remains on reducing the size, increasing the accuracy and strength of products, reducing the response time.

Baumer's developers and engineers, based in locations around the world, are constantly collaborating with leading universities and research centers to ensure that Baumer's well-deserved technological leadership goes into the future and that developed know-how is protected by patents. Baumer always tries to develop solutions that will be the best for the customer's conditions, even if the task is the most difficult from an engineering point of view. It is the solution of complex problems that helps Baumer to reach a new level of quality and reliability and to remain a leader in innovative solutions, staying forth of the needs of the industry and expanding the range of products offered.

The main range of Baumer products consists of the following categories:

- Length measurement actuators. These are devices whose output signal is information about the distance to some, in the general case, uncontrolled object.

- Encoders. Encoders are specialized devices that allow you to determine the angle of rotation of a rotating part (shaft) and fix the speed of its movement.

- Motion detectors. A motion transducer is a signaling device that detects the movement of objects and is used to control the environment or automatically trigger the required actions in response to the movement of objects.

- Presence sensors. Presence sensors are highly sensitive sensors that switch the circuit or generate a signal when an object is detected in the work area.

- Tacho generators. The devices are designed to convert the shaft rotation speed into an output voltage signal.

- Speed limiters. There are a specialized device used to control the speed of rotation of various mechanisms.

- Machine vision. Engine vision cameras are used to monitor the production process and control the quality of manufactured products.

- Filling/empty level measurement. Level sensors are devices used to determine the level of liquid and bulk substances in various containers, tanks, silos or bunkers.

- Various counters. Counters are used for accurate counting of such parameters as length, number of revolutions (tachometers), number of pulses, equipment operating hours, number of mechanism moves.

These products can be applied to a wide variety of fields and industries, such as food processing and packaging equipment, chemical industry, cranes and other lifting equipment, semiconductor and robotic industries, medical equipment and laboratory installation, wind turbines, elevators and trucks, and much more other.

We provide Baumer stock products with worldwide shipping. Contact our specialists to get more information about availability and price.