Bosch Rexroth Ball transfer units

rexroth r165111420

- Number of rails: 4

- Ball diameter: 16 mm

- Ball material: steel

- Ball hardness: 60 HRC

- Separator material: polyamide

r166581420

- Friction coefficient: 0.002 - 0.005

- Noise level: < 50 dB(A)

- Degree of protection IP: IP65

rexroth tr

- Rails: aluminum, steel, stainless steel

- Carriages: aluminum, steel, high-tech plastics

The miniature tolerance ring AN90X23 from Bosch Rexroth is a compact component designed to ensure precise and reliable positioning in pneumatic systems.

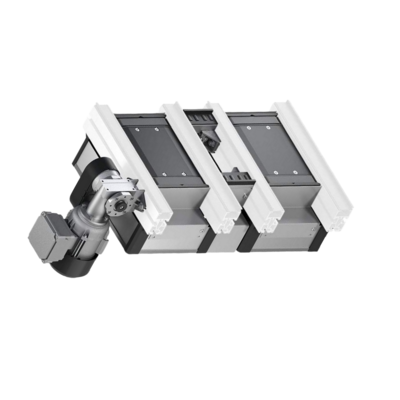

Ball rail systems Acessories LWA 032 SKS FN E 0 from Bosch Rexroth are high-quality single-axis roller bearings designed for the needs of handling and automation technology.

The miniature tolerance ring BN30X15 from Bosch Rexroth is a compact component used to support and center shafts in applications with limited space.

rexroth hmv01

- Type: Power supply unit

- Series: IndraDrive M

- Application: Servo drives

- Efficiency: Up to 95% (with energy recovery)

- Cooling: Internal air

The Ball Transfer Unit KU N22 P MFK from Bosch Rexroth is a compact, modular component designed for moving loads over smooth surfaces. It consists of a housing, a set of steel balls, a sealant and a plastic backing plate.

kwd 025 fns c1 n 1

- Maximum dynamic load: 7,000 N

- Maximum speed: 5 m/s

- Acceleration: 20 m/s²

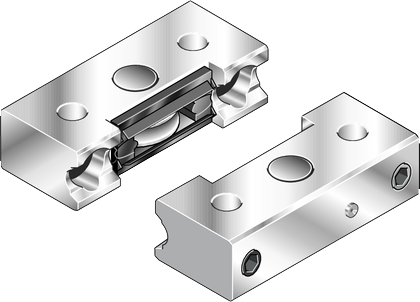

The Miniature Guide Rail Resist NRII MSA 012 BNS H MA AB is a miniature guide rail with high corrosion resistance manufactured by Bosch Rexroth. This rail is designed for use in compact linear guide systems where high precision, rigidity and wear resistance are required.

r036050000

- Screw type: ball bearing

- Nut type: preloaded

- Body material: aluminum

- Protection: IP65

- Operating temperature: from -20°C to +80°C

r044229401

- Bearing type: Ball bearing

- Number of bearings: 4

- Bearing material: steel

- Lubricant type: Lithium-based lubricant

- Maximum load: 200 N

- Static load: 400 N

- Friction moment: 0.15 Nm

Ball transfer units without felt seal – Size 8

KU-B8-OFK

Steel Ball Transfer

Ball transfer units without felt seal – Size 15

KU-B15-OFK

rexroth r053xx15xx

- Dynamic load capacity C [N]: 500

- Maximum permissible linear speed vmax [m/s]: 2

Ball Transfer

rexroth r053xx22xx

- Material: Steel

- Sealing: Rubber

- Temperature range: from -20°C to +100°C

bosch rexroth r1622

- Speed: up to 5 m/s

- Accuracy: up to ±2 μm

- Operating temperature: from -20°C to +80°C

r162282420

Lubrication: Dynalub 510 (recommended)

Material: Steel

r162311420

- Number of videos: 4

- Maximum load: 14.4 kN

- Static load: 8.64 kN

- Dynamic load: 10.08 kN

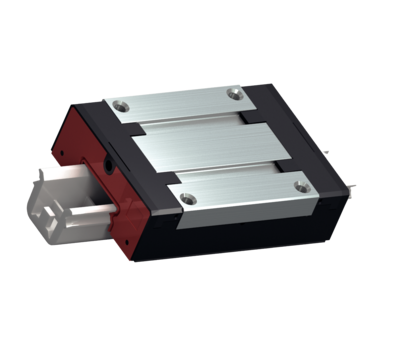

r165122320

- Type: Ball linear carriage

- Series: B.RUNNER BLOCK CS

- Nominal load: 10,000 N

- Static load: 15000 N

- Maximum acceleration: 500 m/s²

- Maximum permissible speed: 5 m/s

r165132320

- Series: R16

- Weight: 1,600 kg

- Bearing type: Ball bearing

- Number of bearings: 4

r165171320

- Maximum permissible speed: 5 m/s

- Maximum acceleration: 500 m/s²

- Load capacity at dynamic torque: 630 Nm

- Static torque load capacity: 830 Nm

r165331320

- Type: Linear carriage

- Series: BALL RUNNER BLOCK

- Permissible speed: 5 m/s

- Acceleration: 20 m/s²

- Weight: 0.75 kg

- Moment of inertia: 0.0003 kgm²

- Temperature range: -20°C to +80°C

r165341420

- Type: Linear carriage

- Series: BALL RUNNER BLOCK

r165381420

- Body: aluminum

- Trolley: carbon steel

- Bearings: ball bearings with separator

- Temperature range: From -20°C to +80°C

r166611420

- Sliding material: steel

- Sealing material: NBR

- Operating temperature: from -20°C to +80°C

- Degree of protection: IP20

r166621420

- type: Sliding trolley

- Series: BALL RUNNER BLOCK

- Case material: Unalloyed carbon steel CS

- Preload class: C1 (low preload)

r166681420

- Maximum static load: 14,400 N

- Maximum dynamic load: 10,800 N

- Gliding speed: up to 2 m/s

- Coefficient of friction: < 0.002

- Noise level: < 50 dB(A)

- Operating temperature: from -20°C to +80°C

r1622 194 20

- Ambient temperature: from -20°C to +80°C

- Humidity: up to 90% (non-condensing)

- Noise level: ≤60 dB(A)

- Degree of protection: IP65

r162221320

- Temperature range: From -20°C to +80°C

- Maximum speed: 5 m/s

- Acceleration Maximum: 10 m/s²

Bosch Rexroth is one of the world's leading manufacturers of motion control and automation equipment and technologies. In this article, we will answer the question “What are ball transfer units?”, and also consider the main characteristics and advantages of these devices, and their application in various industries.

What are Bosch Rexroth Ball Transfer Units?

Bosch Rexroth ball transfer units are components used in various material handling systems, especially conveyor systems. These units provide omnidirectional movement, transferring materials smoothly and accurately in multiple directions. They are typically used on assembly lines, shipping stations, and other industrial environments where the ability to easily move objects in multiple directions is critical.

These ball transfer devices consist of a large support ball surrounded by a smaller ball transfer bearing. This design provides friction reduction and allows heavy loads to be moved easily, reducing the effort required for manual handling and increasing the efficiency of logistics operations.

Key Features and Benefits

Bosch Rexroth ball transfer units are known for their precision engineering and robust construction, making them the preferred choice for a variety of industrial applications. Let's look at the key features and benefits of these devices.

High load capacity

Bosch Rexroth ball transfer units are designed to withstand heavy loads, making them suitable for harsh environments in production and logistics.

Smooth and multi-directional movement

The units provide smooth, easy movement in multiple directions, which is critical for handling materials that need to be maneuvered in tight spaces or rotated easily.

Robust design

Made from high-quality materials such as stainless steel, these devices can withstand harsh environmental conditions and long-term use without compromising performance.

Corrosion resistance

Bosch Rexroth ball drives have corrosion-resistant properties, making them ideal for use in environments where they are exposed to moisture or chemicals.

Versatility

Available in a variety of sizes and configurations, these devices can be integrated into a wide range of systems and applications, from conveyor systems to assembly lines.

Easy to install and maintain

These devices are designed for ease of installation and maintenance, reducing downtime and increasing operational efficiency.

Increased operational efficiency

Providing smooth, multi-directional motion, Bosch Rexroth ball drives significantly improve the efficiency of material handling processes by reducing the time and effort required to move heavy loads.

Cost savings

Rugged and durable, these devices reduce the need for frequent replacement and maintenance, resulting in cost savings for businesses in the long run.

Increased security

The ability to easily move heavy and bulky items reduces the risk of injuries and accidents in the workplace, creating a safer work environment for employees.

Types of Bosch Rexroth Ball Transfer Units

Bosch Rexroth offers a variety of ball transfer units designed to meet the diverse needs of different industries and applications. Here are some of the main types of ball transfer units.

Heavy-duty ball transfer devices

These devices can handle exceptionally high loads, these units are ideal for demanding applications in industries such as automotive and heavy manufacturing.

Miniature ball passing devices

Compact units are suitable for tasks requiring precise and smooth movement of small objects.

Flange-mounted ball transfer units

Such equipment can be mounted using a flange, providing secure mounting and stability.

Ball transfer blocks on studs

Equipped with stud mounting for installation flexibility and easy integration into a variety of installations.

Ball transfer inserts

Easily inserts into pre-drilled holes or fixtures, making them convenient for quick installation or replacement.

Spring-loaded ball transfer devices

Thanks to the spring-loaded mechanism, these devices adapt to the load, providing smooth movement and reducing the impact on the objects being transported.

Low-profile ball transfer units

Their low-profile design makes them ideal for applications where space is limited.

Stainless steel ball transfer units

Constructed from stainless steel, these devices offer excellent corrosion resistance and are suitable for harsh environments.

Applications of Bosch Rexroth Ball Transfer Units

Bosch Rexroth ball transfer units can be used in a wide range of industrial applications. In particular:

- Assembly lines.

- Material handling equipment.

- Conveyor technology.

- Sorting systems.

- Car assembly.

- Handling printed circuit boards.

- Food and beverage industry.

- Package.

- Pharmaceutical industry.

- Aerospace industry.

- Glass and ceramics.

Choosing the Right Ball Transfer Unit for Your Needs

Selecting the right Bosch Rexroth ball transfer unit for your specific application involves considering several key factors. Here's a guide to help you make an informed decision:

- Calculate the maximum weight of the items you need to move. Select a ball transfer unit that can comfortably support this weight.

- Select a unit with a higher than maximum lifting capacity to ensure durability and safety.

- Consider the material of the ball transfer unit. Stainless steel devices are ideal for environments exposed to moisture, and chemicals or where hygiene is critical (such as the food and pharmaceutical industries).

- For aggressive environments, stainless steel or specially coated products provide better resistance and durability.

- Choose between flanged, stud, or push-in units depending on your existing configuration and ease of installation.

- Make sure the device provides smooth, multi-directional motion to suit your application, whether simple conveyor systems or complex sorting and positioning applications.

- For fragile items such as glass, ceramics, or electronics, choose devices designed for delicate handling to minimize the risk of damage.

- For industrial applications involving heavy equipment or automotive parts, select heavy-duty units that can withstand high voltages and loads.

- Make sure the ball transfer unit can operate effectively within the temperature range of your application environment.

Bosch Rexroth Ball Transfer Units Installation and Maintenance

Proper installation and maintenance are critical to ensure optimal performance and longevity of Bosch Rexroth ball transfer units. Here is a detailed guide to installing and maintaining these devices:

- Determine the exact locations where the ball transfer units will be installed. Make sure these areas can support the load and are properly leveled.

- Ensure the mounting surface is clean, level, and free of debris to ensure a stable installation.

- Place the flange block in the designated area.

- Use appropriate bolts or screws to secure the device through the flange holes. Make sure the device is securely secured to prevent it from moving.

- Drill holes in the mounting surface to match the dimensions of the studs.

- Insert the ball transfer assembly studs into the holes.

- Attachment: Tighten the nuts on the studs to securely secure the unit in place.

- Make sure all blocks are aligned correctly to ensure smooth movement of items across the surface.

- After installation, test the ball transfer units by placing a weight on them to check for smoothness and stability.

- Monitor balls and housings for wear. Replace any worn or damaged components promptly to prevent further damage and ensure trouble-free operation.