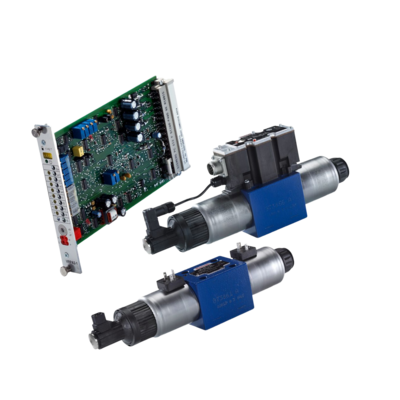

Bosch Rexroth Directional control valves

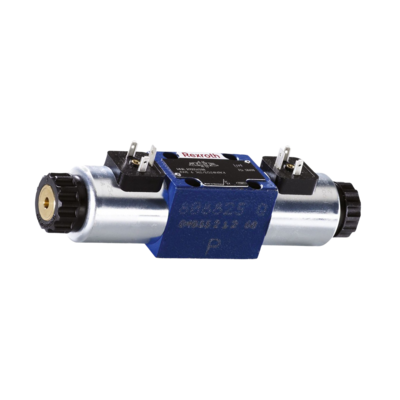

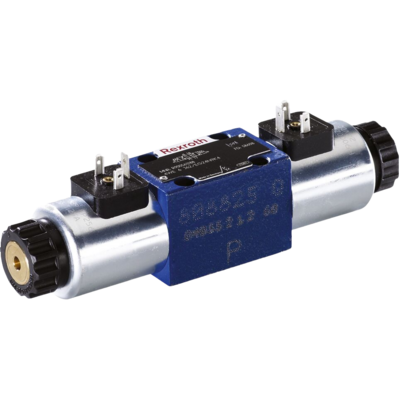

4we 10 d5x eg24n9k4 m Rexroth proportional valve

- Operating temperature: from -20°C to +80°C

- Fluid: HLP mineral oil or equivalent

- Filtration: 10 μm

- Noise level: < 70 dB(A)

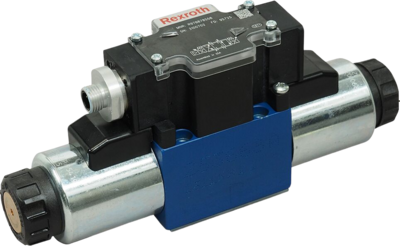

4we6d6x

- Pressure drop: max. 50 bar

- Trigger time: 20-40 ms

- Capacity: 0.4 cm³

- Power consumption: max. 10 W

- Degree of protection: IP65

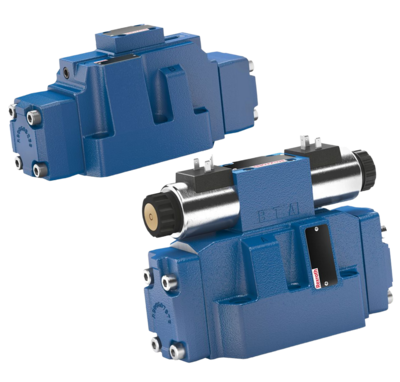

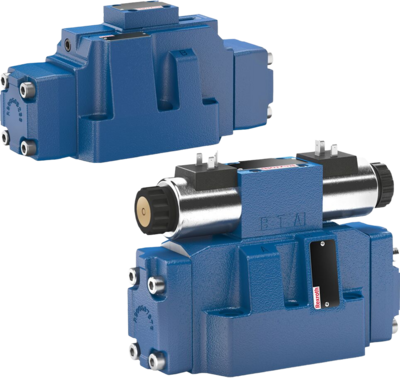

4weh rexroth

- Supply voltage: 12 V or 24 V DC

- Current consumption: Up to 2 A

- Connection type: DIN EN 175301-803

- Degree of protection: IP65

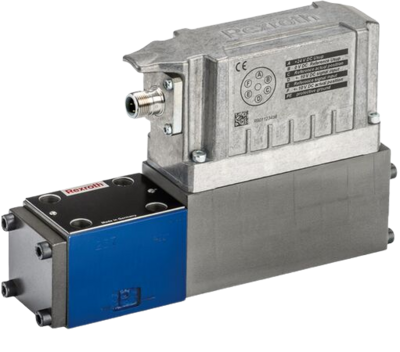

4wrpeh 6 c3 b12l 20 g24k0 a1m

- Stem symbol: C3

- Viscosity: 10-800 sq. mm/s

- Pressure: 250 - 315 bar

- Ambient temperature: -20°C to +50°C

- Liquid temperature: -20°C to +70°C

rexroth r900052621

- Entrance: G1/2

- Output: G1/2

- Connector: DIN 43650

- Noise level: 70 dB (A)

rexroth r900561286

- Power consumption: 25 W

- Current: 1.04 A

- Degree of protection: IP65

- Connector: 3-pin connector according to DIN 175301-803

3we6a6x eg24n9k4

- Supply voltage: 24 V DC

- Current consumption: 2.4 A

- Trigger time: 25 ms

- Pressure relief: Internal

- Piston position in neutral state: Closed

- Connection: DIN 24340 A, ISO 4401-03-02-0-05, NFPA T3.5.1 R2-2002 D03

- Fluid type: Hydraulic oil H, ISO VG 32 - 46

- Liquid temperature: From -20°C to +80°C

- Filtration: 10 μm

4we 10 j5x eg24n9k4 m

- Liquid viscosity: 15 - 350 cSt at 40°C

- Body material: Aluminum

- Coil material: Class F

- Degree of protection: IP65

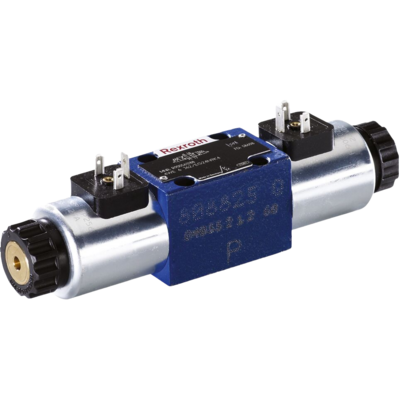

4we10d5x eg24n9k4 m

- Nominal current: 2.5 A

- Coil power: 60 W

- Trigger time: 25 ms

- Release time: 25 ms

4we6c6x eg24n9k4

- Pressure drop: 3 bar

- Internal leakage: 0.1 cm³/min

- External leakage: 0 drops/min

4we6j62

- Viscosity of the working fluid: 10-400 Pa·s

- Working fluid temperature: From -20°C to +80°C

- Filtration of the working fluid: Purity class ISO 6/4.5

4weh22 rexroth

- Type: Directional hydraulic distributor

- Working fluid temperature: -20°C to +80°C (-4°F to 176°F)

- Body material: aluminum

rexroth 4wrae

- Overlap: Internal

- Maximum hysteresis: ≤ 0.1%

- Maximum uncertainty zone: ≤ 0.05%

- Threshold sensitivity: ≤ 0.05%

4wree 6 rexroth

- Nominal voltage: 24 V DC

- Current consumption: max. 2.5 A

- Operating temperature range: from -20°C to +80°C

- Protection class: IP65

4wree 6 e16 2x g24k31 a1v

- Number of sections: 2

- Section type: 3/3 (two-way control)

- Valve position in neutral state: Closed

- Switching time: 25 ms

- Degree of accuracy: 2%

- Maximum switching frequency: 120 Hz

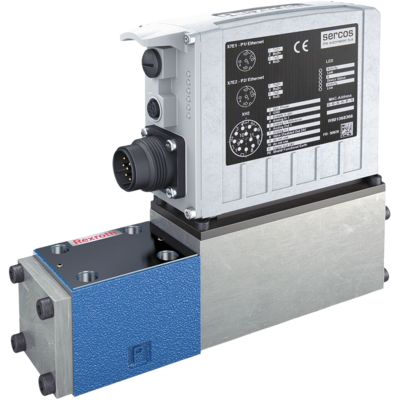

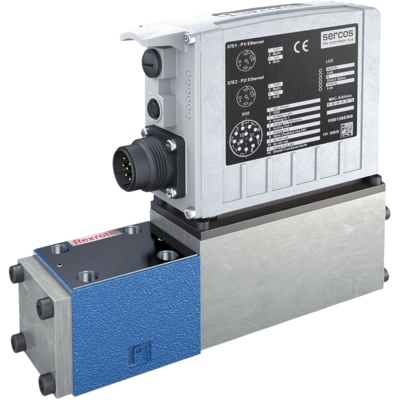

4wrpdh

- Type: Proportional hydraulic distributor with integrated digital axis controller (IAC)

- Series: 4WRPDH

- Sizes: 6, 10

- Maximum flow rate: 100 l/min (26.4 gal/min)

- Safety features: category 4/PL e according to EN 13849-1

4wrpeh 10 c4 b100l 2x g24k0 a1m

- Response time: < 20 ms

- Clearance: < 10 µm

- Feedback Type: LVDT (Linear Differential Alternating Current Transformer)

- Feedback range: ± 5 mm

4wrpeh 6 c3 b12l 2x g24k0 a1m

- Working fluid temperature: From -20°C to +80°C (-4°F to +176°F)

- Viscosity of working fluid: 10...100 mm²/s (32...320 cSt) at working temperature

- Maximum switching pressure: 210 bar (3045 psi)

- Trigger time: 20 ms

- Maximum switching frequency: 120 Hz

4wrpeh 6 c3 b24l 2x g24k0 a1m

- Maximum pressure: 400 bar

- Nominal consumption: 24 l/min

- Maximum consumption: 40 l/min

- Working fluid: Mineral oil HLP / DIN 51524

4wrse rexroth

- Response time: < 20 ms

- Hysteresis: < 1 %

- Body material: Aluminum

- Gasket material: FKM (for mineral oils) or FKM/FFKM (for phosphate esters)

- Degree of protection: IP67

4wrte rexroth

- Supply voltage: +24 V DC

- Current consumption: 250 mA

- Overcurrent protection: Yes

- Short circuit protection: Yes

4wrz rexroth

- Signal type: current or voltage

- Signal range: 4 - 20 mA or 0 - 10 V

- Response time: < 20 ms

- Switching frequency: up to 120 Hz

rexroth 4ws2em10

- Operating voltage range: 21-27 V DC

- Current consumption: 2 A

- Control signal frequency: 0-1000 Hz

- Control signal/displacement ratio: 5 µm/V

- Resistance: 10 kΩ

bosch 0820023026

- Noise level: 65 dB

- Vibration resistance: 10 G

- Impact resistance: 50G

hm20 rexroth

- Nominal supply voltage: 12...35 V DC

- Current consumption: max. 20 mA

- Input resistance: max. 220 ohms

- Response time: < 2 ms

lfa 25 rexroth

- Working fluid temperature: -20°C to +80°C (-4°F to +176°F)

- Viscosity of working fluid: 10 - 350 cSt (at 40°C)

- Filtration of the working fluid: 10 μm

rexroth od15061

- Working fluid temperature: From -20 °C to 80 °C

- Viscosity of the working fluid: From 15 to 380 mm²/s (cSt)

- Degree of protection: IP65

r900561272

- Working fluid temperature: From -20°C to +80°C

- Protection class: IP65

- Weight: 1.2 kg

- Standard mounting brackets: CETOP 5 (F03)

- Electrical connections: 3-pin DIN connector

r900950342

- Spool type: With positive and negative overlap

- Spool stroke: 12 mm

- Response time: 20 ms

- Coil power: 13 W

- Resolution: 12 bits

- Refresh rate: 1 kHz

rexroth vspa2 1

- Nominal current input signal: 4-20 mA

- Current input signal range: 0 ... 20 mA

- Input resistance: 22 kΩ

Directional control valves from Bosch Rexroth play an important role in flow control in hydraulic systems. They are necessary to control the flow direction and amount, allowing you to control the movement and force applied to actuation devices (for example, cylinders or hydraulic motors).

The operating principle of the Bosch Rexroth directional control valve is based on the use of special valves (balls, plungers, or other elements) that move under the pressure of the working fluid and close or open the holes in the distribution plate. This allows the direction and volume of fluid flow to be changed following control signals from the operator or an automatic control system.

Key Features and Benefits

Each device produced by Bosch Rexroth boasts the highest build quality and reliability. Let's find out what features and benefits hydraulic valves provide.

- Precise flow control. Bosch Rexroth guide valves provide high precision in regulating the flow of hydraulic fluid, which is especially important for complex and high-precision hydraulic systems.

- Reliability in operation. Thanks to the use of high-quality materials and advanced production technologies, the valves are highly reliable and durable.

- Variety of models. Bosch Rexroth offers a wide range of valve guides, including spool, ball, and plunger valves, allowing you to choose the optimal solution for your specific application.

- Installation flexibility. The valves are available in a variety of sizes and connection types to allow easy integration into a variety of hydraulic systems.

- Variety of control methods. The valves can be operated manually, electrically, hydraulically, or pneumatically, allowing the most suitable method to be selected for a particular application.

- Compatible with modern control systems. Electrically controlled valves by Bosch Rexroth are easily integrated into automated control systems.

- High-quality materials. Wear-resistant materials guarantee the long service life of the valves even under severe operating conditions.

- Anti-pollution. Some models are equipped with additional protective elements that prevent the entry of contaminants and ensure stable operation.

- Fast and precise control. High speed and precision switching of the valve guides can significantly improve the efficiency of the hydraulic system.

- Reduced losses. Optimized valve design minimizes pressure loss and fluid leakage, improving overall system performance.

- Wide range of applications. Bosch Rexroth guide valves can be used in a wide variety of industries, from mechanical engineering to agriculture and aviation.

- Adaptability to conditions. The ability to select different types and control methods allows the valves to be adapted to specific operating conditions.

- Durability. High quality and durable materials ensure long service life, reducing the need for frequent maintenance and replacement.

- Reduced operating costs. Valve reliability and efficiency help reduce operating and maintenance costs for hydraulic systems.

Types of Rexroth directional valve

Bosch Rexroth offers a wide range of directional valves that provide precise and reliable control of hydraulic fluid flow in a variety of industrial and mobile applications. You can buy Bosch Rexroth check valves of various types. Let's find out which ones in more detail.

Directional poppet type valves

Poppet directional valves (or plug valves) are designed to control the direction of fluid flow. These valves are known for their high sealing properties and ability to prevent leaks when closed. They are ideal for applications where a reliable flow shutdown is required.

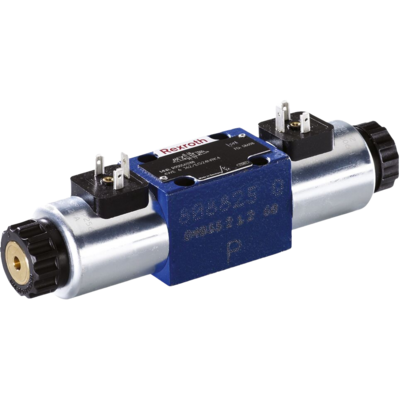

Directional solenoid valves

Bosch solenoid valve use a solenoid to control the direction of fluid flow. They can be configured in various patterns (2/2, 3/2, 4/2, 4/3), allowing efficient flow control in different directions and combinations.

Flow control valves

Control valves are designed to control the rate of fluid flow in a hydraulic system. They provide precise flow control, which allows you to optimize system operation and increase its efficiency.

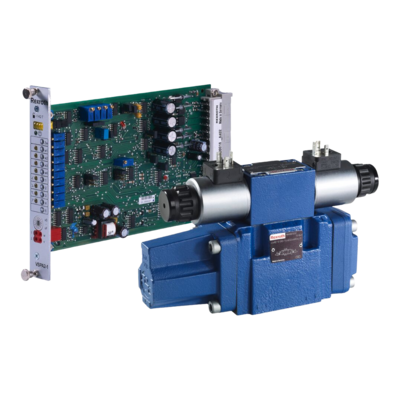

Proportional directional control valves

Bosch Rexroth proportional directional valves provide smooth and precise control of the direction and amount of fluid flow. These valves use proportional rexroth solenoid valve to precisely control flow depending on the input signal.

Applications of Bosch Rexroth Directional Control Valves

Bosch Rexroth guide valves are used in hydraulic circuits in various industries. Let's take a closer look at these areas.

- Machines and equipment. Control of the movement of working parts of machine tools, presses, and other machines.

- Metalworking. Controls the feed and return stroke of hydraulic cylinders, ensuring precise positioning and force.

- Agricultural machinery. Control of movement and functions of hydraulic systems of tractors, combines, seeders, and other machines.

- Irrigation systems. Control of water and working fluid flows in irrigation systems.

- Construction equipment. Control the movement of excavators, bulldozers, cranes, concrete mixers, and other heavy equipment.

- Hydraulic drives. Application in hydraulic hammers, concrete cutters, and other equipment.

- Airplanes and helicopters. Control of hydraulic systems of landing gear, flaps, control surfaces, and other actuators.

- Ground equipment. Use in-ground equipment for aircraft maintenance and repair.

- Production equipment. Control of hydraulic presses, assembly lines, and other machines.

- Vehicles. Use in suspension, braking, and steering systems of trucks, buses, and special equipment.

- Hydropower. Control of hydraulic systems of hydroelectric power plants, including turbines and valves.

- Oil and gas industry. Use in drilling rigs, lifting systems, and other hydraulic mechanisms.

- Robotics. Control motion and forces in robotic systems to ensure precise task execution.

- Conveyor systems. Control of hydraulic drives of conveyors, elevators, and other equipment.

- Forestry equipment. Control of movement and functions of hydraulic systems of harvesters, forwarders, and other machines.

- Woodworking machinery. Application in hydraulic systems of saws, presses, and other equipment.

- Mining equipment. Control of hydraulic systems of excavators, drilling rigs, crushers, and other machines used in the mining industry.

- Marine hydraulic systems. Control of rudders, mooring devices, cranes, and other hydraulic mechanisms on ships.

- Equipment for ports. Application in hydraulic systems of port cranes, container loaders, and other equipment.

Choosing the Right Directional Control Valve for Your Application

To choose the right Bosch Rexroth inline check valve, you should pay attention to certain factors that will help you not make a mistake. Below we will study them in more detail.

- Determine what type of hydraulic system and application you are selecting a valve for. For example, this could be mobile equipment, industrial equipment, mechanical engineering, etc.

- The choice depends on the type of valve you need. Bosch Rexroth offers various types of directional valves, such as proportional, control, unloader, check, safety, etc.

- Determine the maximum operating pressure and flow required for your application. This is important for selecting a valve that can operate under these conditions.

- Consider how the valve will be controlled (mechanical, electrical, proportional, etc.).

- Determine the mounting method (flanged, threaded, recessed) and connection types that suit your system.

- Consider operating conditions such as temperature, pollution, humidity, etc.

From Bosch Rexroth servo valve to Rexroth air valve, Eltra Trade offers a vast selection of valves to meet your every need. Whether you're looking for industrial, commercial, or residential applications, our extensive inventory has the perfect valve for you.