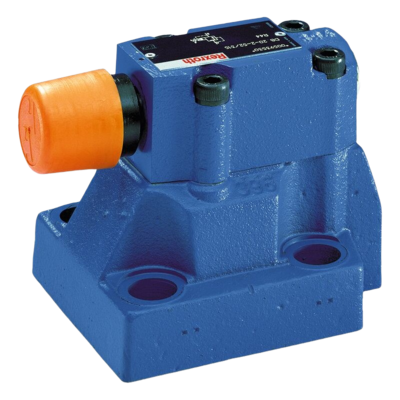

Bosch Rexroth Pressure valves

IN STOCK!

Code: VSO-SE 055279109701000

Operating pressure: up to 210 bar

Maximum. flow rate: 30 l/min.

bosch 0821002003

- Control type: Direct action

- Reset type: Quick reset

- Air viscosity: 20 cSt at 20°C (0.002 Pa·s at 68°F)

- Protection class: IP65

- Standard: DIN ISO 15558

- Certificates: CE, RoHS

db20k rexroth

- Viscosity of the working fluid: From 15 to 350 cSt (mm²/s)

- Noise level: < 70 dB(A)

- Certification: CE, ATEX

rexroth dbw20

- Working fluid temperature: From -20°C to +100°C

- Viscosity of working fluid: Up to 350 cSt at 40°C

- Accuracy class: 0.5 pagal ISO 5128-1

- Thread for connecting the manometer: G 1/4

rexroth dr10

- Operating temperature: From -20°C to +80°C

- Oil viscosity: From 10 to 1000 cSt

- Standards: ISO 6149, DIN 24353

rexroth r901

- Working fluid temperature: From -20°C to +100°C

- Viscosity of working fluid: From 10 to 1000 cSt at 40°C

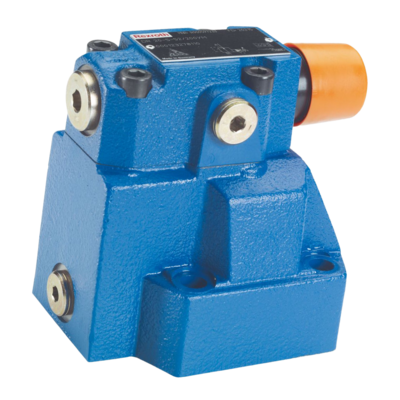

The DBAW25BH2 2X 350 6EG24K4 is a hydraulic overload protection unit from Bosch Rexroth. It is used to protect hydraulic systems from damage caused by excessive pressure. The unit consists of two independent safety valves that are manually adjustable.

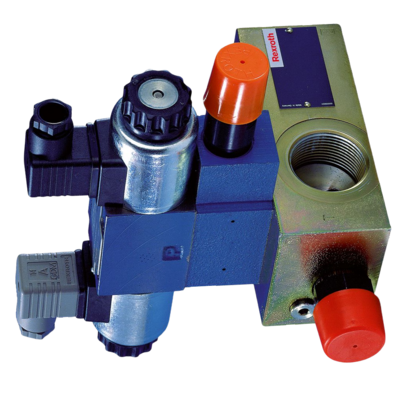

The DR6DP2-5X/25Y is a pressure reducing valve from Bosch Rexroth designed to reduce pressure in hydraulic systems. It is used in a wide range of applications, including industrial machinery, mobile machinery and construction equipment.

PRESSURE RED.VALVE INTERMEDIATE PLATE ZDR6DP2-4X/210YMV

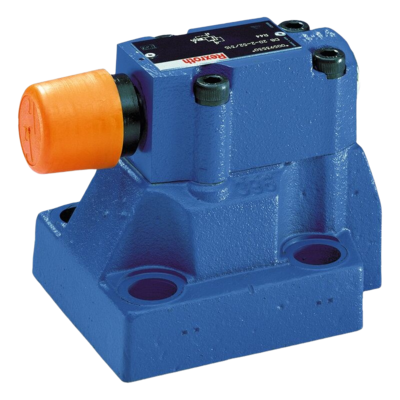

Bosch Rexroth Pressure Control Valve

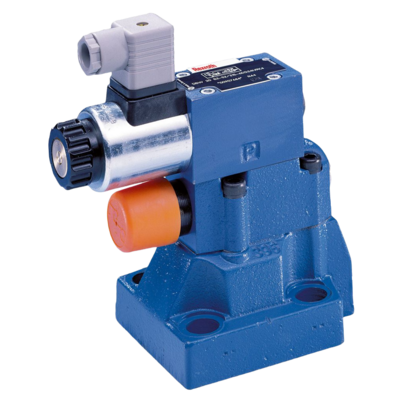

Pressure relief valve, direct operated

DBDS 6 K1X/315

The ZDR10VP5 3X 315YMV is a high-performance industrial hydraulic valve designed to reliably reduce pressure to a specified value. This pilot operated spool valve has a mechanical actuation mechanism.

The ZDR6DP7 4X 75YM is a direct-operated pressure reducing valve in a sandwich plate design with secondary circuit pressure limitation. It is used to reduce system pressure in hydraulic drives.

db 20 rexroth

- Number of pressure levels: 5

- Materials: Steel, Aluminum

rexroth db20

- Operating temperature: From -20°C to +120°C

- Viscosity of the working fluid: From 10 to 1000 cSt

rexroth dbdh

- Compliance with standards: ISO 6149, DIN 24340

- IP protection class: IP67

- Certification information: CE, ATEX

r900726604

- Operating temperature: from -20°C to +80°C

- Storage temperature: from -40°C to +80°C

- Protection class: IP67

- Body: aluminum

- Sealing: EPDM

r900727801

- Operating temperature: from -20°C to +80°C

- Maximum drain pressure: 10 bar

- It is recommended to use hydraulic oil with a viscosity of 15 to 350 cSt (mm²/s) at 40°C.

Code: VU-N-38 043119009901000

Maximum. working pressure: 350 bar

Maximum. flow: 30 l/min

Pressure relief valve, direct operated

DBDS 6 K1X/100

DBDS 6 K1X/200

DBDS 6 K1X/400

DBDS 10 K1X/100

DBDS 10 K1X/200

DBDS 10 K1X/315

DBDS 10 K1X/315V

DBDS 10 K1X/400

DBDS 10 K1X/50

DBDH 6 K1X/200

Pressure valves from the Bosch Rexroth manufacturer are key components in hydraulic systems. They provide control and regulation of fluid pressure to maintain safe and efficient system operation. Bosch Rexroth pressure valves are designed to prevent overpressure levels, protect system components from damage and ensure stable operating pressure.

The principle of operation of such devices is that initially, you set the maximum pressure, above which the valve begins to open. This set pressure can be adjusted using an adjusting screw or a special mechanism on the valve. When system pressure exceeds a set limit, hydraulic fluid begins to force against the piston or diaphragm inside the valve. This pressure creates a force that overcomes the force of the spring that holds the valve closed.

Once the force from fluid pressure exceeds the force of the spring, the valve opens, allowing some of the fluid to flow into the relief line or back into the reservoir, thereby reducing the system pressure to the set level. When the system pressure drops below a preset limit, the spring returns the piston or diaphragm to its original position, closing the valve and stopping fluid discharge.

Types of Bosch Rexroth Pressure Valve

Bosch Rexroth offers a wide range of pressure valves that provide reliable and precise pressure control in hydraulic systems. These valves are designed for system protection, maintaining stable pressure, and ensuring safe operation. Let's look at the main types of Bosch Rexroth pressure valves.

Mechanical pressure relief valves

Mechanical relief valves relieve excess system pressure, preventing damage and ensuring safe operation. They automatically open when a preset pressure is reached and return to the closed position when the pressure drops to a safe level.

Proportional pressure relief valves

Rexroth proportional relief valve provide more precise and smooth pressure control. They are controlled by an electrical signal, which allows you to flexibly change the set pressure values depending on operating conditions.

Mechanical pressure reduction valves

Mechanical pressure reducing valves reduce fluid pressure to a certain level necessary for the operation of individual system components. They maintain a stable outlet pressure regardless of changes in inlet pressure.

Proportional pressure reducing valves

Proportional pressure reducing valves provide precise and smooth pressure reduction using an electrical signal. This allows for more flexible pressure adjustment depending on system requirements.

Pressure reducing and relieving valves

Pressure reduction and relief valves perform two functions: they do pressure limiting to a predetermined level and relieve excess pressure, preventing overload of the system. These valves ensure stable system operation under changing conditions.

Pressure sequence valves

Sequential pressure valves control the sequence of operations in a hydraulic system, opening when a certain pressure is reached. They ensure the correct order of operation of the various components of the system.

Pressure cut off valves

Pressure cut off valves automatically stop fluid flow when a set pressure is reached. This protects the system from overloads and prevents equipment damage.

Pressure compensators

Pressure compensators maintain constant system pressure to compensate for load changes. They ensure the stable operation of the system and prevent pressure spikes.

Pump safety blocks

Pump safety units include safety valves and other devices to protect pumps from overpressure and overload. They ensure the safe and reliable operation of pumping stations.

Applications of Bosch Rexroth Pressure Valves

Bosch Rexroth hydraulic components have a wide range of industrial applications. Below we will take a closer look at the areas in which you can use pressure valves.

Construction equipment

Pressure valves monitor and regulate the pressure in the hydraulic systems found on excavators, loaders, and cranes, thereby ensuring their safe and efficient operation.

Production lines

Such devices ensure stable pressure in the hydraulic systems of automated production lines, preventing overload and equipment damage.

Machines and presses

Bosch Rexroth pressure valves are needed to protect the hydraulic systems of machines and presses from excess pressure, which is important for processing accuracy and equipment durability.

Oil and gas industry

In oil and gas production, transportation, and processing systems, pressure valves are used to maintain stable pressure and prevent emergencies.

Automotive industry

Pressure valves ensure the stable operation of hydraulic systems on assembly lines, protecting equipment from overload and ensuring accurate operations.

Shipbuilding

Pressure valves control the pressure in a boat's hydraulic systems, such as anchor lifting and rudder systems, to ensure they operate reliably.

Agricultural machinery

Pressure valves are used to protect the hydraulic systems of agricultural machinery attachments. Thus, these devices ensure their reliable operation under changing operating conditions.

Hydroelectric power plants

Bosch Rexroth pressure valves control water flows and protect turbine hydraulic systems from overpressure to ensure safe and efficient operation.

Aircraft hydraulic systems

Pressure valves monitor and regulate the pressure in hydraulic flight control systems and landing gear of aircraft, ensuring they operate safely.

Robotic systems

Pressure valves provide precise control of pressure in robot hydraulic actuators, essential for precise and complex operations.

Automated production lines

Used to maintain stable pressure in hydraulic systems of automated lines, preventing interruptions and ensuring uninterrupted operation.

Submersibles

To control the pressure in the hydraulic systems of underwater vehicles, which is important for their operation in difficult underwater conditions, pressure valves from Bosch Rexroth are used.

How to Choose the Right Bosch Rexroth Pressure Valve

Selecting the correct pressure valve is an important step in ensuring reliable and efficient hydraulic system operation. So let's look at the criteria that you should consider to buy Bosch Rexroth pressure valves that meet your needs.

- Determine the operating pressure of the system. Ensure that the valve's maximum operating pressure exceeds or meets your hydraulic system requirements to ensure safe operation.

- Consider the type of control. Depending on your system needs, choose a mechanical, electro-hydraulic, or bosch proportional valve to provide precise and reliable pressure control.

- Evaluate flow characteristics. Select a valve with suitable flow characteristics to avoid excessive resistance and ensure optimal system performance.

- Check compatibility with your production environment. Ensure that valve materials are resistant to fluid and operating conditions such as temperature and chemical attack.

- Consider the size and installation parameters. Select a valve that physically fits your equipment and is easy to install in the given space.

- Please note additional features. Some Bosch Rexroth valve models have additional features such as damping and check valves that can improve system performance.

- Check compliance with standards. Ensure that the valve meets the required standards and regulations to ensure safety and durability.

- Consult technical experts. If in doubt, contact Bosch Rexroth or your dealer who can help you make the right choice based on the specific requirements of your system.

Installation and Maintenance Tips

Correct installation and regular maintenance of valves guarantee their reliable and durable operation, minimizing the risk of malfunctions and downtime. Below we will provide you with some valve installation tips that you should know before you add equipment into the hydraulic circuits.

- Ensure that the valve is installed according to the manufacturer's instructions, including the correct position and orientation, to ensure optimal operation.

- Use the correct tools and equipment to connect the valve to the system, avoiding over-tightening the fasteners, which could damage the seals.

- Check valves regularly for leaks, damage, or signs of wear to help identify and correct potential problems early.

- Clean valves and replace filters in your system regularly to prevent clogging and ensure smooth hydraulic system performance.

Rexroth solenoid or Rexroth sensor Visit our website today to explore our valve offerings and place your order!