Bosch Rexroth Screw drives

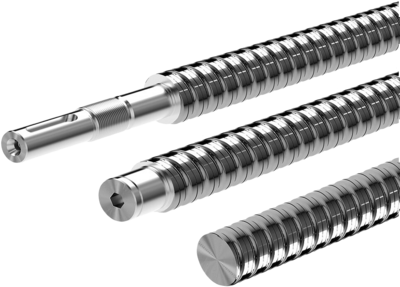

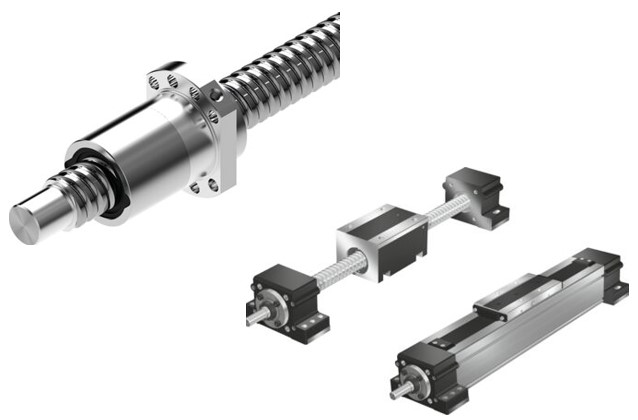

The BALL SCREW 50X5RX3.5 (T9) from Bosch Rexroth is a precision screw mechanism designed for linear movements requiring high precision and efficiency. It is used in a variety of industries.

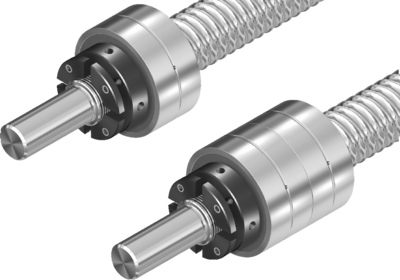

The ZEM-E-S 8X2.5RX1.588-3 from Bosch Rexroth is a high-precision ball screw designed for linear motion applications. This ZEM-ES cylindrical single nut block is a member of the Miniature series and is characterized by its nominal diameter and right-hand helix direction, which are integral to its performance.

The LAN-B-A 30 BG is a support bearing from Bosch Rexroth that is used to fix linear guides in industrial applications.

ms2n05

- Nominal voltage: 230/400 V AC

- Network frequency: 50/60 Hz

- Rated current: from 2.2 to 18.5 A

- Maximum current: up to 27.8 A

- Power factor: 0.85

- Efficiency class: IE2

Ball Nut

Single nut with flange FEM-E-B, size 20 x 10R x 3?-?4

FEM-E-B 20X10RX3-4

Single nut with flange FEM-E-S, size 20 x 20R x 3.5?-?2

FEM-E-S 20X20RX3.5-2

Single nut with flange FEM-E-S, size 25 x 10R x 3?-?4

FEM-E-S 25X10RX3-4

fem es R151234013

Single nut with flange FEM-E-S, size 32 x 10R x 3.969?-?5

FEM-E-S 32X10RX3.969-5

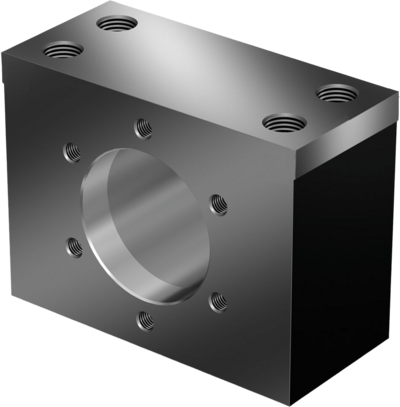

The HOUSING MGS 25X5/10/20X0 from Bosch Rexroth is a housing for ball screw drives used in precision motion control systems. It is a key component that ensures the integration and functionality of these systems.

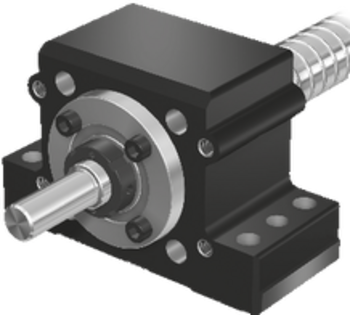

The SEC-F-Z 12 is a fixed bearing unit from Bosch Rexroth designed for use with stub screw drives.

bosch rexroth hcs02

- Supply voltage: 1/3 AC 200 - 500 V

- Power supply frequency: 47.5 - 66 Hz

- Ambient temperature: -10°C to +40°C

- Vibration duration: 0.35 mm peak-to-peak

FEM-E-B 20X5RX3-4

FEM-E-B 25X5RX3-4

FEM-E-B 25X10RX3-4

FEM-E-B 32X5RX3,5-4

FEM-E-B 40X5RX3,5-5

FEM-E-B 40X20RX6-3

FEM-E-B 40X40RX6-3

FEM-E-B 50X10RX6-6

ZEM-E-S 16X5RX3-4

FEM-E-S 16X5RX3-4

FEM-E-S 20X5RX3-4

FEM-E-S 25X5RX3-4

FEM-E-S 25X25RX3.5-2

FEM-E-S 32X5RX3.5-4

SEM-E-C 32X5RX3,5-4

FEM-E-S 32X20RX3.969-2

FEM-E-S 32X32RX3.969-2

FEM-E-S 40X5RX3.5-5

FEM-E-S 40X10RX6-4

Bosch Rexroth screw drives are mechanical devices that are part of linear actuators that convert rotational motion into linear motion. They are widely used in various industries to ensure accurate and reliable movement in automated systems. Bosch Rexroth offers several types of screw drives, each of which has its own features and advantages.

Key Features and Benefits

Bosch Rexroth screw drives are widely used in various industrial applications due to their high reliability, precision, and durability. They are used in automation, machine tool building, robotics, and other fields that require precise linear motion control. Below we outline the key features and benefits of Bosch Rexroth screw drives.

High accuracy

Bosch Rexroth screw drives provide precise positioning and repeatability through precision manufacturing and strict quality control.

Low coefficient of friction

Special coatings and high-quality materials reduce friction and wear, which increases the efficiency and durability of screw drives.

Wide range of sizes and configurations

Bosch Rexroth screw drives are available in a variety of sizes and configurations, allowing you to choose the optimal solution for your specific application. They can also be adapted to individual customer requirements.

High load capacity and load resistance

Such devices can withstand high dynamic and static loads thanks to durable structural materials and ensure reliable operation even under high loads.

Durability and reliability

The use of high-quality materials and advanced production technologies guarantees long service life and reliable operation of screw drives. And you don't need frequent maintenance thanks to durable components.

Cost efficiency

The high efficiency and low operating costs associated with Bosch Rexroth screw drives help reduce total cost of ownership. Long service life and low maintenance requirements reduce costs.

Types of Bosch Rexroth Screw Drives

Bosch Rexroth offers a wide range of high-performance screw drives designed for different applications and requirements. These screw drives provide precise linear motion, high load capacity, and efficiency in a variety of industrial applications. Each type has unique characteristics and benefits suitable for specific applications. Let's take a closer look at Rexroth screw drive models.

Ball Screw Assemblies

Bosch Rexroth ball screws are known for their high efficiency and precision. They use recirculating ball bearings to minimize friction and provide smooth, precise linear motion. These assemblies are ideal for applications that require high-speed operation, low noise, and high positioning accuracy, such as CNC machine tools, robotics, and semiconductor manufacturing equipment.

Roller Screw Assemblies

Roller screw units are designed for applications requiring high load capacity and long service life. Unlike ball screws, they use threaded rollers to transfer the load between the screw and the nut. This design provides higher load capacity and rigidity, making them suitable for heavy-duty applications such as injection molding machines, heavy lifting equipment, and aerospace applications.

Planetary Screw Assemblies

Planetary screw assemblies provide a unique solution that combines the advantages of ball and roller screws. They feature planetary rollers that provide high load capacity and efficiency with less play and wear. These assemblies are ideal for applications requiring high precision, reliability, and ruggedness, such as industrial automation, medical equipment, and high-performance drives.

Applications of Bosch Rexroth Screw Drives

Bosch Rexroth screw drives are widely used in various industries due to their high precision, reliability, and durability. Let's find out where they can be used.

Mechanical engineering and machine tools

In the mechanical and machine tool industry, Bosch Rexroth screw drives are used to provide precise positioning and high-speed motion. They are used in computer numerical control (CNC) machines, lathes and milling machines, as well as drilling and grinding machines. High precision and low noise make them ideal for such high-precision applications.

Robotics and automation

In robotics and automation, Bosch Rexroth screw drives provide the precise and smooth motion needed to operate robots and automated systems. They are used in assembly lines, automated warehouses, and other systems where high-speed and precision movement is required.

Automotive industry

In the automotive industry, where precision engineering is required, screw drives are used in a variety of manufacturing processes, including welding, assembly, and component testing. They help ensure high precision and reliability, which is especially important for the production of cars and components with high-quality requirements.

Aerospace industry

In the aerospace industry, Bosch Rexroth screw drives are used to create highly accurate and reliable motion systems used in the production and maintenance of aircraft and space equipment. They provide high load capacity and long service life, which is especially important for such mission-critical applications.

Medical equipment

In medical equipment, screw actuators are used to provide precise movement and positioning in devices such as surgical robots, CT scanners, and analyzers. Their high precision and reliability make them ideal for use in medical technology, where every detail matters.

Industrial automation

In industrial automation systems, screw drives are used to control various electromechanical systems and processes, providing high efficiency and accuracy. They are used in packaging lines, conveyor systems, and other automated processes.

Energy and heavy engineering

In the energy and heavy engineering industries, Bosch Rexroth screw drives are used in heavily loaded applications such as hydraulic presses, lifting devices, and mining equipment. Their high load capacity and durability make them ideal for use in extreme conditions.

Choosing the Right Screw Drive for Your Application

Selecting the right Rexroth screw drives for a specific application requires you to consider many factors to ensure optimal performance, reliability, and durability. Let's consider the main criteria that will help in choosing automation components:

- Determine the maximum load the drive must support. Consider dynamic and static loads. For severe operating conditions, roller or planetary screw drives are preferred.

- Determine the required positioning accuracy. For high-precision applications (such as CNC machines or medical equipment), ball screw drives are best suited.

- Determine the required travel speed and acceleration. Ball screw drives offer high speed and low noise, making them ideal for high-speed applications.

- Consider environmental conditions such as temperature, humidity, dust, and dirt. For severe and extreme operating conditions, choose drives with increased protection and durability.

- Estimate the expected life of the drive and maintenance requirements. Planetary and roller screw drives typically have high durability and require minimal maintenance.

- Consider the overall dimensions and design features of the drive. Ensure that the selected drive meets the mounting and installation requirements.