Bosch Rexroth Transfer system

r044221201

- Maximum speed Without lubrication: 0.5 m/s

- Maximum speed With lubrication: 2 m/s

- Maximum acceleration: 10 m/s²

bosch 3842999716

- Torque: 100 Nm

- Speed: up to 3000 rpm

- Connection dimensions: 8 mm x 12 mm

- Degree of protection: IP65

- Certificates: CE, RoHS

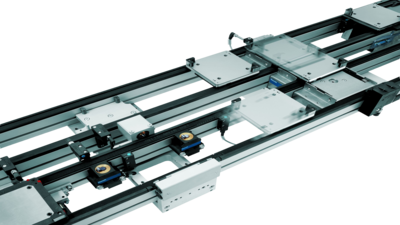

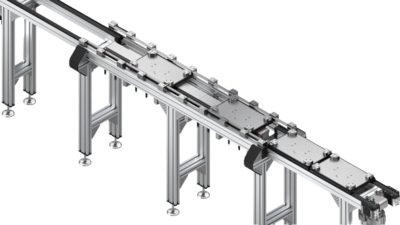

rexroth ts1

- Operating temperature range: from -10°C to +50°C

- Protection level: IP65

- Compatible with clean rooms and dry rooms

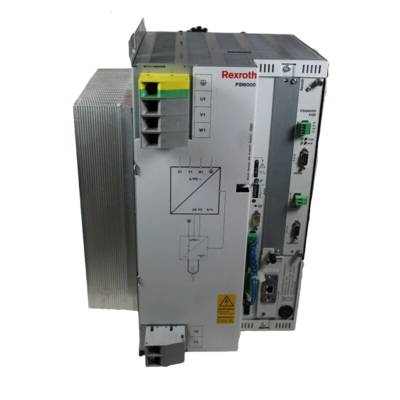

rexroth psi 6000

- Power factor: 0,95

- Input voltage: 380-480 V AC, 3 phases

- Input current: Max. 1.5 kA

- Switching frequency: 10 kHz

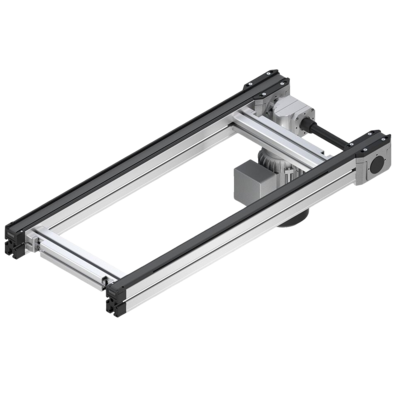

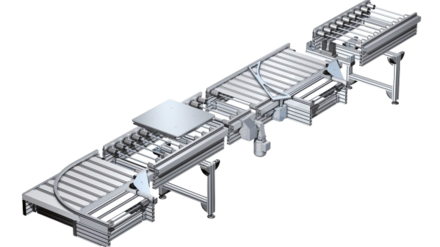

bosch ts5

- Aluminum construction

- Modular construction

- Protection IP65

- A wide range of drives

- Various options for surface treatment

- A wide range of accessories

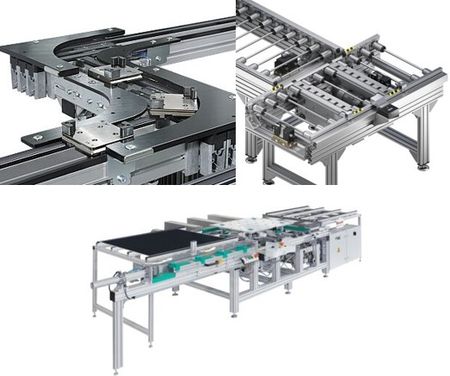

ts2 bosch

- Conveyor width: 400 mm, 600 mm, 800 mm

- Conveyor height: 200 mm, 300 mm, 400 mm

- Minimum turning radius: 1.5 m, 2 m, 2.5 m

PROXIMITY SWITCH M12-M12 SN=4MM L=70

Bosch Rexroth is one of the leading specialists who specializes in the development and production of hydraulic and pneumatic control systems, as well as other drive technology. They also produce Rexroth conveyor solutions such as transfer systems. They are complex solutions for mechanical energy transmission and can be used by you in various industries. These systems include components and technologies for transmitting rotational motion and force from one component to another. Let's take a closer look at rex Rexroth transfer units.

Types of Transfer Systems

Bosch Rexroth cares about its customers, so it provides a wide range of transfer systems that you can use in completely different industrial sectors. Below, we will consider the main types of Rexroth transfer systems.

Belt drives

These systems use belts and pulleys to transmit torque between shafts. They are popular among buyers because they can effectively mitigate shock and vibration. Belt drives are widely used in equipment with high rotation speeds and relatively low torque.

Chain drives

Such systems include chains and sprockets that transmit motion mechanically. They are characterized by high strength and the ability to work under challenging conditions, such as high loads and aggressive environments. They are also often used in conveyor systems and heavy equipment.

Gearboxes and geared motors

These devices are designed to reduce rotation speed and increase torque. They are used in various drive systems, providing precise motion control and efficient power transmission in industrial applications.

Clutches and brakes

Clutches connect and disconnect shafts, transmitting torque, while brakes stop or slow down shaft rotation. These components are essential for motion control and can provide safety and control in mechanical systems.

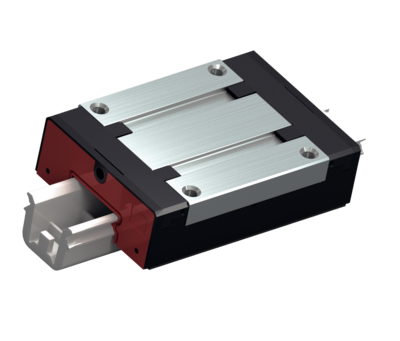

Linear actuators and linear motion systems

These systems convert rotary motion into linear motion. Linear actuators include ball screws and linear guides that provide precise and smooth movement in one direction. You can use them in CNC machines, robotics, and automated systems.

Motion control systems

These transfer systems include electronics, sensors, and software that provide precise control and coordination of motion in industrial and automated systems. They allow you to optimize productivity and improve operational accuracy, which is especially important in complex manufacturing processes.

Key Benefits of Rexroth Transfer Systems

If you decide to order products from Bosch Rexroth, you can be sure of their highest quality. Each Bosch Rexroth transfer system has several advantages that we will discuss below.

- Reliability and durability. Rexroth transfer system components are made of high-quality materials, which ensures their durability and ability to withstand high loads and extreme operating conditions.

- High efficiency. Transfer systems are designed to minimize energy losses, which allows for high power transfer efficiency. This is important for reducing energy costs and increasing productivity.

- Ease of maintenance and installation. Rexroth transfer system components are designed for easy installation and maintenance, reducing installation, repair time, and maintenance costs.

- Accuracy and control. Motion control systems and linear drives provide high positioning accuracy and motion control. This is critical in areas such as factory automation and robotics.

- Adaptability. Bosch Rexroth's solutions are highly flexibility, so you can quickly adapt and expand them to meet changing production requirements or specific operating conditions.

Applications for Bosch Rexroth Transfer Systems

Bosch Rexroth transfer systems are widely used in various industries due to their reliability, efficiency, and precision. Let's find out which ones.

Automotive industry

Assembly lines use robotic stations, test equipment, and transfer systems. These ensure precise positioning and coordination of the various stages of the assembly process.

Food and packaging industry

This industry uses transfer systems in production lines, packaging machines, and liquid-filling equipment. At the same time, it is essential for you that the systems are hygienic, reliable, and comply with safety standards.

Power and renewable energy

Wind turbines, solar panels, and other installations require precise motion control and efficient power transmission. Rexroth transfer systems play a crucial role in these applications.

Metal and mining industry

Such harsh operating conditions require reliable and robust transfer systems that withstand heavy loads and operate in aggressive environments. These systems include conveyors, crushing plants, and metal processing equipment.

Logistics and warehouse systems

Rexroth transfer systems are used in automated storage, retrieval, conveyor, and sorting systems. They allow you to ensure the fast and precise movement of goods and materials.

Robotics and automation

Motion control systems and linear drives from Bosch Rexroth play an essential role in robotic systems and automated workstations, ensuring the precision and coordination of robot movements.

Aerospace and defense

High precision and reliability of transfer systems are essential in the production and testing of aerospace equipment, as well as in defense systems and military equipment.

How to Choose the Right Rexroth Transfer System for Your Needs

Want to choose the right transfer system for your specific needs? Consider the tips below to make it easy.

- Determine what loads and torques need to be transmitted. This includes calculating the maximum and rated torque that the application will require.

- Know what speed the system must support. This will help you choose the right gearbox and motor combination.

- Environmental factors such as temperature, humidity, dust, or aggressive chemicals can significantly impact the choice of materials and protective coatings. It's crucial to consider these when selecting a transfer system.

- Considering the duration and frequency of operation is crucial, as it can determine the level of reliability required for the components. Heavy-duty use may necessitate components with increased reliability.

- If high-precision control is required, choose highly-resolution systems with minimal backlash.

- Highly dynamic applications (e.g., robotics) require systems with high response speed.

- Consider the possibility of future expansions and upgrades. Choosing a system that allows you to easily add or improve new components may be worth it.

Eltra Trade is a certified Rexroth transfer system supplier. This guarantees you the highest quality equipment, competitive prices, and fast delivery.