Bosch Rexroth Valves

IN STOCK!

Code: VSO-SE 055279109701000

Operating pressure: up to 210 bar

Maximum. flow rate: 30 l/min.

4we 10 d5x eg24n9k4 m Rexroth proportional valve

- Operating temperature: from -20°C to +80°C

- Fluid: HLP mineral oil or equivalent

- Filtration: 10 μm

- Noise level: < 70 dB(A)

4we6d6x

- Pressure drop: max. 50 bar

- Trigger time: 20-40 ms

- Capacity: 0.4 cm³

- Power consumption: max. 10 W

- Degree of protection: IP65

4weh rexroth

- Supply voltage: 12 V or 24 V DC

- Current consumption: Up to 2 A

- Connection type: DIN EN 175301-803

- Degree of protection: IP65

4wree 10 e75 22 g24k31 a1v

- Operating temperature range: from -20°C to +80°C

- Fluid type: HLP mineral oil according to DIN 51524

- Liquid viscosity: from 15 to 100 cSt (at operating temperature)

- Liquid filtration: at least 10 microns

- Connection type: threaded G 1/2

4wrpeh 6 c3 b12l 20 g24k0 a1m

- Stem symbol: C3

- Viscosity: 10-800 sq. mm/s

- Pressure: 250 - 315 bar

- Ambient temperature: -20°C to +50°C

- Liquid temperature: -20°C to +70°C

bosch 0821002003

- Control type: Direct action

- Reset type: Quick reset

- Air viscosity: 20 cSt at 20°C (0.002 Pa·s at 68°F)

- Protection class: IP65

- Standard: DIN ISO 15558

- Certificates: CE, RoHS

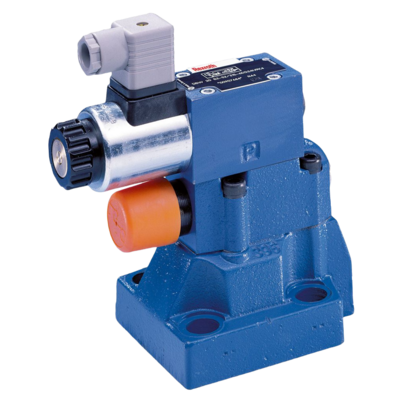

db20k rexroth

- Viscosity of the working fluid: From 15 to 350 cSt (mm²/s)

- Noise level: < 70 dB(A)

- Certification: CE, ATEX

rexroth dbw20

- Working fluid temperature: From -20°C to +100°C

- Viscosity of working fluid: Up to 350 cSt at 40°C

- Accuracy class: 0.5 pagal ISO 5128-1

- Thread for connecting the manometer: G 1/4

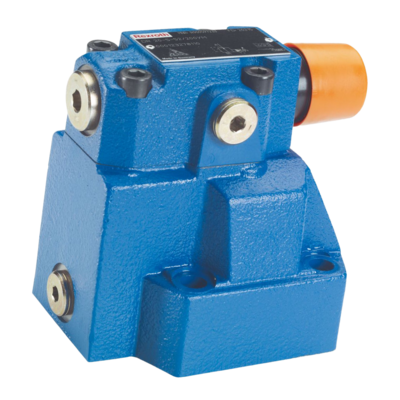

rexroth dr10

- Operating temperature: From -20°C to +80°C

- Oil viscosity: From 10 to 1000 cSt

- Standards: ISO 6149, DIN 24353

hed8

- Maximum current: 5 A

- Maximum power: 25 VA

- Supply voltage: 12 V to 24 V DC

- Trigger time: less than 20 ms

- Reset time: less than 10ms

lfa 32

- Supply voltage: 24 V DC

- Current consumption: max. 2 A

- Control type: manual, hydraulic or electric

rexroth od15

- Type: mineral oil, synthetic oil

- Purity class: ISO 4406 19/16

- Working viscosity: 32-100 cSt (at 40°C)

rexroth r900052621

- Entrance: G1/2

- Output: G1/2

- Connector: DIN 43650

- Noise level: 70 dB (A)

rexroth r900517812

- Noise level: 65 dB (A) at maximum flow

- Protection class: IP67

- Mineral oils HLP, HLP-D, HLP-M according to DIN 51524

- Synthetic oils according to DIN 51524

- Fire-resistant liquids according to DIN 51524

rexroth r900561286

- Power consumption: 25 W

- Current: 1.04 A

- Degree of protection: IP65

- Connector: 3-pin connector according to DIN 175301-803

rexroth r901

- Working fluid temperature: From -20°C to +100°C

- Viscosity of working fluid: From 10 to 1000 cSt at 40°C

rexroth vspa2

- Supply voltage: 24 V DC

- Operating voltage range: 18 ... 30 V DC

- Current consumption: ≤1 A

- Storage temperature: from -40°C to +80°C

- Body material: aluminum

z1s6 rexroth

- Cost factor: 0.65

- Pressure relief: 0.5 bar

- Trigger time: 20 ms

- Noise level: < 70 dB(A)

SEAL KIT LR 25.1X/

The Z2FRM6TB2-2X/32QRV from Bosch Rexroth is a high-performance industrial hydraulic sandwich valve designed to reliably regulate oil flow to a set value. This check valve with spool has the symbol T T and is capable of withstanding the maximum pressure indicated by its product group ID.

2frm 6b rexroth

- Viscosity of the working fluid: From 10 to 800 mm²/s

- Working fluid temperature: From -20°C to +80°C

- Connection ports: G1/2 for case size 6

3we6a6x eg24n9k4

- Supply voltage: 24 V DC

- Current consumption: 2.4 A

- Trigger time: 25 ms

- Pressure relief: Internal

- Piston position in neutral state: Closed

- Connection: DIN 24340 A, ISO 4401-03-02-0-05, NFPA T3.5.1 R2-2002 D03

- Fluid type: Hydraulic oil H, ISO VG 32 - 46

- Liquid temperature: From -20°C to +80°C

- Filtration: 10 μm

4we 10 j5x eg24n9k4 m

- Liquid viscosity: 15 - 350 cSt at 40°C

- Body material: Aluminum

- Coil material: Class F

- Degree of protection: IP65

4we10d5x eg24n9k4 m

- Nominal current: 2.5 A

- Coil power: 60 W

- Trigger time: 25 ms

- Release time: 25 ms

4we6c6x eg24n9k4

- Pressure drop: 3 bar

- Internal leakage: 0.1 cm³/min

- External leakage: 0 drops/min

4we6j62

- Viscosity of the working fluid: 10-400 Pa·s

- Working fluid temperature: From -20°C to +80°C

- Filtration of the working fluid: Purity class ISO 6/4.5

4weh22 rexroth

- Type: Directional hydraulic distributor

- Working fluid temperature: -20°C to +80°C (-4°F to 176°F)

- Body material: aluminum

rexroth 4wrae

- Overlap: Internal

- Maximum hysteresis: ≤ 0.1%

- Maximum uncertainty zone: ≤ 0.05%

- Threshold sensitivity: ≤ 0.05%

4wree 6 rexroth

- Nominal voltage: 24 V DC

- Current consumption: max. 2.5 A

- Operating temperature range: from -20°C to +80°C

- Protection class: IP65

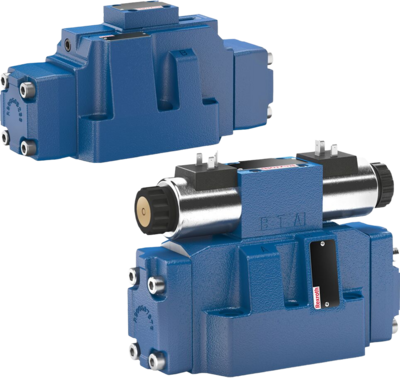

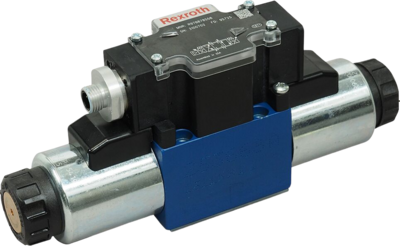

Leading the way in industrial automation worldwide, Bosch Rexroth offers a variety of goods and services for industrial, engineering, and manufacturing operations. The company's valves are a top option for industrial automation because of their reputation for precision, dependability, and integration skills.

A wide range of valves from bosch rothrex are available, each tailored to fulfill specific needs in pneumatic and hydraulic systems. In automated operations, these valves are essential for managing the pressure, flow, and direction of liquids or gases.

The Role of Valves in Industrial Automation

Valves are fundamental components in industrial automation systems, responsible for controlling the movement of fluids and gases within machinery and equipment. In automated systems, precise control over these elements is crucial for efficient and reliable operation. Valves help manage various aspects of industrial processes, including:

- Flow Control: Valves determine the rate at which fluids or gases move through a system. This control is essential for maintaining consistent production and avoiding disruptions.

- Pressure Regulation: Valves maintain safe pressure levels within a system, preventing damage to equipment and ensuring optimal performance. This is especially important in hydraulic and pneumatic applications.

- Directional Control: Valves dictate the direction in which fluids or gases flow. This functionality is vital for controlling the movement of machinery and enabling complex automated processes.

Valves are employed in a broad variety of industrial automation applications, ranging from straightforward on/off actions to intricate multi-directional systems. They are utilized in sectors including manufacturing, automotive, aerospace, energy, and others where dependability and accuracy are crucial.

Bosch Rexroth valves types

1. Cartridge valves

Compact and modular in design, cartridge valves are simple to install and maintain. They can be used in various hydraulic systems to perform various functions such as flow direction, pressure, speed and flow control.

Advantages:

- Compactness: Valves are small in size, making them ideal for use in hydraulic systems with limited space.

- Modularity: Cartridge valves can be easily assembled and disassembled, making them convenient for maintenance and repair.

- Versatility: Valves can be utilized in a variety of hydraulic systems since they are available in so many different forms and combinations.

- Cost-effectiveness: Cartridge valves are a cost-effective solution for hydraulic systems because they are easy to install and maintain.

- High performance: Valves from Bosch Rexroth offer excellent performance and dependability and are constructed from premium materials.

2. Check valves

Only one direction of fluid flow is permitted with non-return valves. They are used to prevent backflow of fluid in hydraulic systems.

Advantages:

- Prevent backflow: In hydraulic systems, Bosch Rexroth check valves stop backflow and undesired pressure variations by allowing fluid to flow only in one direction.

- Simple design: Check valves have a simple design that makes them reliable and durable.

- Easy installation: Valves made by Bosch Rexroth are simple to install and maintain.

- Wide range of applications: Valves made by Bosch Rexroth are suitable for a variety of hydraulic systems, such as those found in mobile, industrial, and agricultural equipment.

- High performance: High-quality materials are used to create Bosch Rexroth check valves, which also offer excellent performance and dependability.

3. Directional control valves

Directional valves control the flow direction of fluid in hydraulic systems. There are numerous varieties to choose from, such as electric, pneumatic, and manual valves.

Advantages:

- Flow Direction Control: In hydraulic systems, Bosch Rexroth directional valves are used to regulate the direction of fluid flow. This makes it possible to precisely position and operate hydraulic actuators, like motors and cylinders.

- Wide range of types: Valves are available in a wide range of types including manual, pneumatic, electric and proportional valves. This makes them suitable for use in various hydraulic systems.

- Simple design: Directional valves have a simple design that makes them reliable and durable.

- Easy installation: Bosch Rexroth directional valves are easy to install and maintain.

- High performance: Valves are made of high quality materials and provide high performance and reliability.

4. Flow control valves

Flow regulators control the fluid flow rate in hydraulic systems.

Advantages:

- Flow control: Flow control valves are used in hydraulic systems to control the fluid flow rate. This enables the exact control of hydraulic actuator speed, such as that of motors and cylinders.

- Wide range of types: There is a large variety of Bosch Rexroth flow controllers to choose from, such as fixed value and pressure compensated models.

- Simple design: Bosch Rexroth flow controllers have a simple design that makes them reliable and durable.

- Easy installation: Bosch Rexroth flow controllers are easy to install and maintain.

- High performance: High-quality materials are used to create Bosch Rexroth flow controllers, which also offer excellent performance and dependability.

5. Pressure valves

Pressure regulators are used to control fluid pressure in hydraulic systems.

Advantages:

- Pressure control: Pressure valves are used to control fluid pressure in hydraulic systems. This allows you to protect hydraulic components from damage caused by pressure overload and ensure smooth and precise operation of hydraulic actuators.

- Wide range of types: Valves are available in a wide range of types, including proportional pressure regulators, fixed value pressure regulators and relief valves.

- Simple design: Pressure regulators have a simple design that makes them reliable and durable.

- Easy installation: Pressure valves are easy to install and maintain.

- High performance: Bosch Rexroth pressure regulators are made of high quality materials and provide high performance and reliability.

Choosing the right Bosch valve

When choosing a Bosch Rexroth valve, it is important to consider a number of parameters to ensure it working properly and meeting your needs. Here are some of the key factors that which should be taken into account:

1. Valve type

- Cartridge Valves: Compact, modular valves that are easy to install and maintain.

- Check Valves: Allows fluid flow in one direction only.

- Directional valves: Control the direction of fluid flow.

- Flow regulators: Control the liquid flow rate.

- Pressure regulators: Control fluid pressure.

2. Pressure

- The maximum operating pressure of the valve must be higher than the maximum pressure in your system.

- Some valves are available with different pressure ratings.

3. Spending

- The maximum flow rating of the valve must be higher than the maximum flow in your system.

- Some valves are available with different flow rates.

4. Joining

- The type of valve connection must match the type of connection in your system.

- Threaded, flanged and modular connections are commonly available.

5. Material

- The valve material must be resistant to the fluid used in your system.

- Steel, brass and stainless steel are commonly used.

6. Functional capabilities

- Some valves have additional features such as manual control, pneumatic or electric control, proportional control, etc.

- Choose a valve with features that meet your needs.

7. Size

- Make sure you have enough space to install the valve.

- Valve sizes may vary depending on type and model.

Selecting the right Bosch Rexroth valve is essential for efficient and reliable industrial automation. The correct choice depends on several factors, including flow rate, pressure rating, and durability. Eltra Trade offers a comprehensive catalog of Bosch Rexroth valves to fit a variety of needs.

If you are not sure which valve to choose, a rexroth pilot valve or rexroth pressure control valve, or you need additional information about their characteristics, Eltra Trade's expert managers are ready to offer you advice and support.