Burkert 2-2 Way Valves

IN STOCK!

6213-EV-A10,0AAMSGM83-6-024/DC-10

In Stock!!!

A-normally closed, inlet port 1 (P/NC), 1,20 mm (3/64 inch)

IN STOCK!!!

00164579 2000-B-2-20,0-EE-VA-SA93-C-D *AF93+NK51

IN STOCK!!!

6213-EV-A13,0BBMSGM84-5-024/50-08

IN STOCK!!!

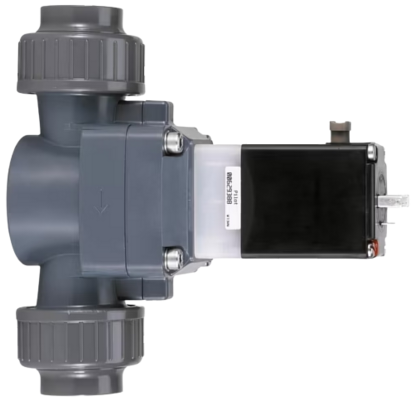

Actuator for 2/2-way angle seat valve, 25mm (1")

Burkert type 6223 is 2/2-way proportional solenoid valves

Burkert 120680 2-way solenoid valve

- Type: 2/2-way

- Size: 1.5 mm

- Working pressure: 0-2 bar

- Type: usually closed

Bürkert 120721 2/2-position solenoid valve

- Type: 2/2-position

- Action: direct

- State in the absence of voltage: closed

Burkert 125317 Solenoid valve

- Valve type: 2/2

- Mode: normally closed

- Body: AISI 316L stainless steel

- Actuator: electromagnet

Bürkert 136307 2/2-way solenoid valve

- Valve type: 2/2-way

- Thread: G1/4''

- Coil: 24V DC

- Body material: PP

Burkert 160737 Rotary angle valve

- Type of valve: Rotary angle

- Number of positions: 2

- Hole diameter: 1 inch (25 mm)

- Body material: AISI 316L stainless steel

Burkert angle seat valve

2/2 - A - normally closed

Burkert 178859 Valve

- Valve type: 2/2-position angle valve

- Control signal: pneumatic

- Body material: brass (gun metal)

- Sealing material: PTFE

Bürkert 187072 2/2-way butterfly valve

- Suitable for use with steam

- Has a high throughput

- Has a long service life

- Easily integrates with Bürkert's ELEMENT automation units

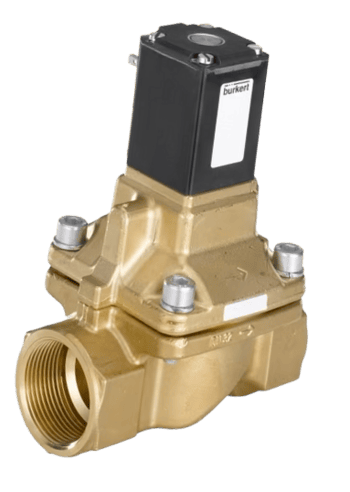

Burkert 189860 Valve

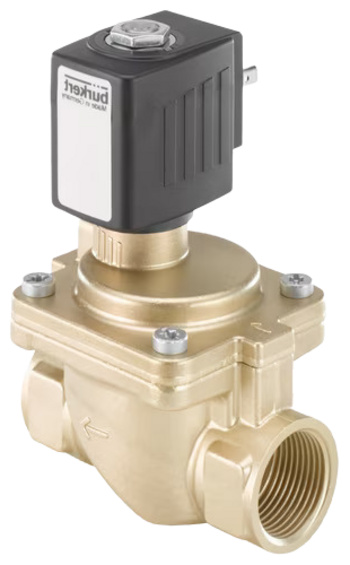

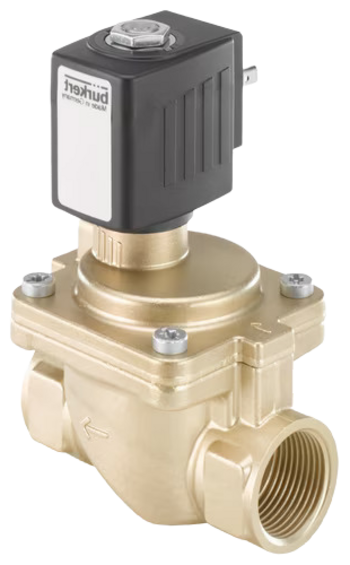

- Valve type: 2/2-way, servo-driven

- Nominal diameter: 25 mm (1 inch)

- Maximum working pressure: 25 bar

- Body material: brass

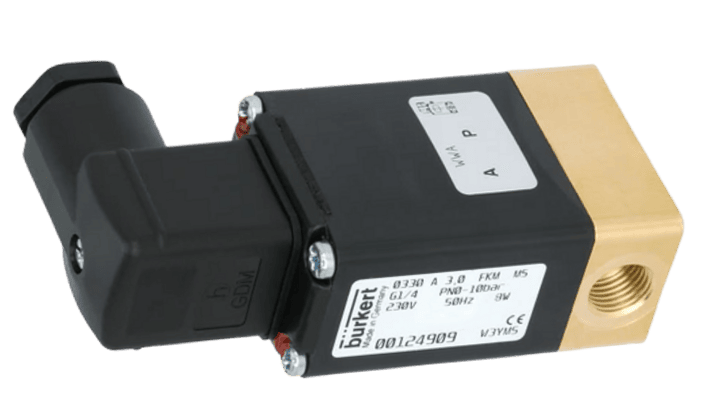

Bürkert 20293 Solenoid valve 2/2-way

- Body material: brass.

- Connection type: internal thread G1/4.

- Power supply voltage: 24 V DC.

- Sealing material: FKM (fluoroplastic).

- Operating temperature range: 0-90 °C.

Burkert 210892 2/2-way solenoid valve

- The valve body is made of brass and the diaphragm is made of NBR (nitrile rubber).

- The valve has 1/2" NPT fittings. NPT, which allows it to be connected to standard pipelines.

- The valve has an operating pressure of up to 10 bar and an operating temperature of -10 to 80 degrees Celsius.

Burkert 221889 Valve

- Valve type: 2/2-position, normally closed

- Fitting diameter: 40 mm (1 1/2 inches)

- Operating pressure: 0.2-16 bar

- Power supply voltage: 24 В

Burkert 239396 Valve

- Type: 3-port rotary valve

- Material: AISI 316L stainless steel

- Threaded connection: 1/4" NPT

- Maximum working pressure: 16 bar

Bürkert 246287 Valve

- Valve type: 2/2-way diaphragm valve

- Construction: normally closed

- Outlet diameter: 10 mm (3/8 inch)

- Operating pressure: 0 to 10 bar

Burkert 295610 2/2-way solenoid valve

- High quality workmanship: the valve is made of high quality materials and meets the highest quality standards.

- Durability: the valve has a robust design and can operate in harsh environments.

- Wide range of operating parameters: the valve has a wide range of operating parameters, which allows it to be used in various industrial applications.

- Easy to install and maintain: the valve has a simple design that ensures easy installation and maintenance

Burkert 299246 Solenoid valve

- Valve type: Two-position, normally closed (NC)

- Body material: PEEK

- Diaphragm material: FFKM

- Operating pressure: -1 to 5 bar (-15 to 73 psi)

Burkert 355089 Valve

- Valve type: 2/2-position, normally closed

- Body material: stainless steel AISI 316L

- Operating pressure: 0.2-10 bar

- Supply voltage: 24 V DC

Burkert 42050 two-position solenoid valve

- Hole size: 20 mm

- Kv-value: 6 m3/h

- Maximum pressure difference: 6 bar

- Maximum temperature: 50 °C

- Protection class: IP65

- Type of electromagnet: 24 V DC

- Weight 0.2 kg

Burkert-463616 2/2-way angle seat valve

- valve type: 2/2-way

- Rotation angle: 90°

- Body: brass

- Working pressure: up to 16 bar

Burkert 463626 2/2-way angle seat valve

- Valve type: 2/2-way

- Valve design: angular

- Body material: stainless steel AISI 316L

- Maximum working pressure: 16 bar

Bürkert 49229 2-way solenoid valve with servo

- Type: 2-way

- Class: А

- Normally closed

- Working pressure: 0-16 bar

- Operating temperature: 0-90 °C

Burkert 55423 Solenoid valve

- Diameter of the connection: G 1/2

- Material of the working element: FKM

- Copper body with threaded connection

- Can be used for various media

Servo-assisted 2/2-way diaphragm valve

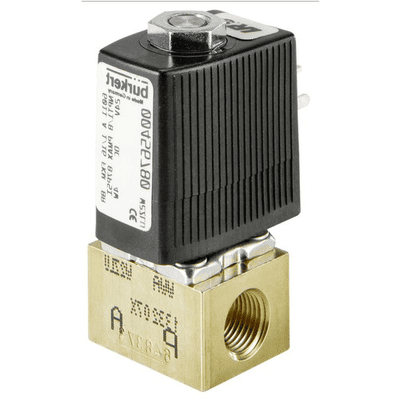

burkert 0330 c is a compact, direct-acting solenoid valve designed for precise control of fluids.

Direct-acting 3/2 or 2/2 -way pivoted armature valve, Burkert 0330 Type

Burkert 2/2 Way Valves

Burkert is a German company specializing in developing and manufacturing fluid control systems and components. Burkert's product range includes solenoid valve technology, sensors, transmitters, controllers, and other devices for controlling fluids such as liquids and gases. In particular, today we will talk about Burkert 2 2 solenoid valves, which we will discuss below.

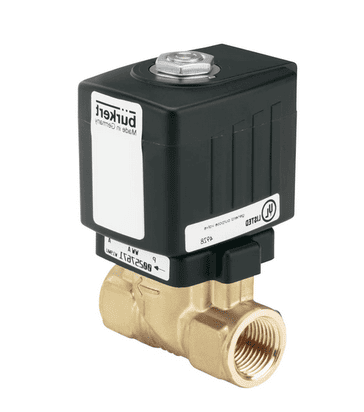

What Are Burkert 2/2 Way Valves?

Burkert 2/2 way valves refer to a type of solenoid valve. The "2/2" designation indicates the valve's configuration, specifically that it has two ports and two positions. In a 2/2 valve, there are two ports - one for the inlet of fluid and one for the outlet. Also, there are two possible positions: open or closed. These valves are commonly used in fluid control applications to regulate the flow of liquids or gases.

Key Features and Benefits

Burkert valve selection includes a wide range of devices, including 2 way valves. The company is considered one of the best manufacturers of solenoid valves in the world, therefore these products have many useful features and benefits, which we will discuss below.

Features

- 2/2 way valves have two ports: one inlet and one outlet. This design allows you to control the flow of fluid by opening or closing the valve.

- These devices can be designed as normally open (NO) or normally closed (NC). In the normally open state, the valve allows fluid to flow when not actuated, and in the normally closed state, the valve prevents flow until actuated.

- Such valves can be actuated manually, pneumatically, electrically, or through other means depending on the application requirements.

- These valves are versatile and find applications in various industries, including water treatment, chemical processing, pharmaceuticals, and more.

- Burkert 2/2 way valves are designed to be compact, making them suitable for installations where space is limited.

Benefits

- Efficient control of fluid flow allows you for precise regulation and on/off functionality.

- These valves are designed for reliability, ensuring consistent performance over time.

- Depending on the model and application, 2/2 way valves can offer a cost-effective solution for fluid control needs.

- Many valves are designed for easy maintenance, with features such as replaceable seals and straightforward disassembly.

- In automated systems, these valves can contribute to energy efficiency by allowing precise control and minimizing waste.

Applications of Burkert 2/2 Way Valves

Burkert 2/2 way valves, like other similar valves, find applications in a wide range of industries where precise control of fluid flow is essential. The versatility of these valves makes them suitable for various processes. Let’s discuss some common 2-2 way valve applications.

Water treatment

Burkert 2/2 way valves are used in water treatment systems for controlling the flow of water, chemicals, or other fluids. They can be employed in processes such as filtration, purification, and chemical dosing.

Chemical processing

In chemical plants, these valves are used to control the flow of chemicals through different stages of production. The valves can be selected based on the chemical compatibility of their materials.

HVAC systems

Heating, ventilation, and air conditioning (HVAC) systems use 2/2 way valves to control the flow of fluids such as water or refrigerants, helping regulate temperature and maintain efficiency.

Automotive industry

In automotive manufacturing, these valves can be used for controlling fluids in processes such as cooling systems, lubrication, and hydraulic systems.

Pneumatic systems

Burkert 2/2 way valves are commonly used in pneumatic systems for controlling the flow of compressed air. They play a crucial role in automation and control applications.

Medical equipment

In medical devices and equipment, these valves are utilized for controlling the flow of gases and liquids in applications such as anesthesia machines and diagnostic equipment.

Textile industry

Textile manufacturing processes often involve the precise control of fluids for dyeing, finishing, and other operations. 2/2 way valves can be employed in these applications.

Oil and gas

In the oil and gas industry, these valves are used for controlling the flow of fluids in various stages of extraction, refining, and transportation processes.

Laboratory equipment

Laboratories often use 2/2 way valves for controlling the flow of fluids in analytical instruments, chromatography systems, and other laboratory equipment.

Burkert 2/2 Way Valves in the Pharmaceutical Industry

In the pharmaceutical industry, Burkert 2/2 way valves play a crucial role in ensuring precise control of fluids and gases throughout various processes. For example, these valves are used for precise dosing and dispensing of pharmaceutical ingredients. This is critical when accurate control of the flow of liquids or gases is essential to maintain the quality of the final product.

Also, pharmaceutical processes often involve the use of filtration systems to remove impurities. Burkert 2/2 solenoid valve can be used in these systems to control the flow of fluids through filters, ensuring efficient and controlled filtration. Moreover, in the production of biopharmaceuticals and vaccines, bioreactors and fermentation processes require precise control over nutrient addition, aeration, and other parameters. Such devices are used to regulate the flow of media and gases in these systems.

As for hygiene, pharmaceutical manufacturing facilities implement strict standards. Burkert 2/2 way valves are utilized in CIP systems to control the flow of cleaning solutions and sanitizing agents during the cleaning process, ensuring the equipment is thoroughly cleaned.

During the lyophilization process, where pharmaceutical products are freeze-dried, Burkert 2/2 way valves can be used to control the flow of refrigerants and other fluids critical to the drying process and contribute to the controlled application of coatings and formulations during tablet manufacturing processes, ensuring uniformity and quality.

Burkert 2/2 Way Valves in Food and Beverage

In the food and beverage industry, Burkert 2/2 way valves are widely utilized for controlling the flow of liquids and gases in various processes. These valves play a critical role in maintaining the quality, safety, and efficiency of production. These devices are used in liquid filling and dispensing applications for beverages, sauces, and other liquid food products. The precise control of flow ensures accurate filling volumes and maintains product consistency. By the way, these valves are employed to control the mixing and blending of ingredients, which helps achieve uniformity in taste and texture. Just like in pharmaceuticals, hygiene is paramount in the food and beverage industry that's why Burkert 2/2 way valves are also used in CIP systems.

As for the processes of pasteurization and sterilization, these devices help to carry it out by controlling the flow of heat exchange media. This is critical to ensuring the safety and shelf life of food and beverage products. 2/2 valves are used to control the transfer of liquids between different stages of the production process, such as from mixing tanks to filling lines or from storage tanks to bottling and packaging lines to control the flow of liquids during the filling and sealing of containers.

In the transportation of powdered or granular food ingredients, Burkert valves can be used in pneumatic conveying systems to control the flow of air or other gases. Such valves also play a role in adding flavors and colors to food and beverage products, ensuring precise control over the quantity and distribution of these additives.

Selecting the Right Burkert 2/2 Way Valve

Selecting the right Burkert 2/2 way valve involves considering several factors to ensure that the device meets the specific requirements of your application. Here are some key considerations when choosing the right one for you.

- Consider the type of fluid (liquid or gas) that will be flowing through the valve. Ensure that the materials used in the valve are compatible with the characteristics of the fluid to prevent corrosion or contamination.

- Check the temperature and pressure ratings of the valve. Ensure that the valve can handle the operating conditions of your application without compromising its performance or integrity.

- Determine the required flow rate for your application and choose a valve size that can accommodate that flow. Consider factors such as pipe size and the desired flow control precision.

- Burkert offers valves in various materials, including stainless steel, brass, and plastic. Select the material that is suitable for the specific application and that complies with industry standards, especially if the valve will be in contact with food or pharmaceutical substances.

- Decide on the preferred actuation method for the valve. Burkert valves can be actuated manually, pneumatically, electrically, or through other means. Choose the method that aligns with your control system and application requirements.

- Ensure that the selected Burkert 2/2 way valve complies with relevant industry standards and regulations. This is especially important in industries like pharmaceuticals and food, where strict hygiene and safety standards apply.

- Consider the maintenance requirements of the valve. Some valves are designed for easy maintenance, with features like replaceable seals or easy disassembly. Also, consider the expected lifecycle of the valve.

- Evaluate the environmental conditions in which the valve will be installed. Factors such as ambient temperature, humidity, and exposure to corrosive substances should be taken into account.

- If your application involves automated control systems, ensure that the Burkert 2/2 way valve can seamlessly integrate with your existing control infrastructure.

While ensuring that the selected valve meets all technical requirements, consider the budget constraints of your project. Burkert offers a range of valves with different features and price points.