Burkert Parts for Sensors & Valves

IN STOCK!!!

2518-A-BCS/UC-00-3-N50-00-0-00000

250 V / 10A / -30,00 - 90,00 °C / IP65/67

IN STOCK!!!

Graphite seal, DN50

- Burkert easy fluid control SYS

- 641115

- Graphite seal

Process rotary valve

- High quality

- Reliability

- Easy to maintain

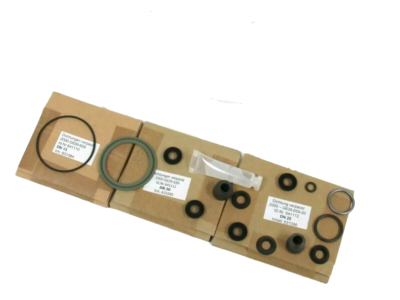

Burkert 233591 repair seal kit

- Stem seal

- Housing seal

- Plunger seal

- Siphon seal

Burkert 418598 Plastic fitting

- The fitting is made of high-quality polyethylene, which is resistant to aggressive environments and has a long service life.

- The connection is made by welding the sleeve, which ensures tightness and reliability.

- It has small dimensions and weight, which facilitates its installation and transportation.

burkert 2508

- Type: form A cable plug

- Protection: class IP 65

- Material: polyamide

- Maximum current: 10 А

Burkert-323217 SideControl

- High level of control accuracy

- Wide range of adjustment

- Stable operation in a wide temperature range

- Easy installation and maintenance

- Type 8611

- Item No. 210206

Positioner top 70 mm for actuator 230X

Type 8692

- Type 8793

- Item No. 317978

- Type 8792

- Item No. 318036

burkert solenoid valve repair kit contains all the necessary components to restore valve performance. It usually includes:

- Consolidation

- Membranes

- Springs

- Nuts

- washers

Burkert 1067

- Temperature range: From -10°C to 60°C.

- Power supply: 24 V DC.

Pneumatic rotary actuator

Rotary pneumatic actuator

Pneumatic Swivel Actuator

Pneumatic rotary actuator

Butterfly valve, bare shaft

Butterfly valve, bare shaft

Aluminium coated / polyamide

Electromotive 2 way globe prop. valve

Valve block 8644 11mm 12-bank

Communicator

Burkert Parts

Burkert is a leading global supplier of fluid control systems and solutions. The company offers various components and products designed for fluid handling, measurement, and control in multiple industries. Below, we will take a closer look at Burkert components.

Optimizing Sensor Performance with Burkert Parts

Optimizing sensor performance with Burkert parts leverages their expertise in precision engineering, quality materials, and advanced technology. Below, we will look at several ways to optimize work with Burkert parts for sensors.

High-quality materials

The selection of materials for Burkert sensor components ensures that the sensors can withstand harsh environmental conditions, resist corrosion, and maintain their performance over a long period.

Precision engineering

The company pays special attention to precision engineering in the design and production of Burkert spare parts for sensors. The result is sensors with tight tolerances, providing accurate and reliable measurements.

Intelligent touch technologies

Burkert offers intelligent sensor technologies that provide additional features such as real-time monitoring, diagnostics, and communication capabilities. Smart sensors provide predictive maintenance, allowing users to troubleshoot potential problems before they affect sensor performance or cause system failures.

Elevating Valve Reliability with Burkert Technology

The use of Burkert technology can make a significant contribution to improving valve reliability in a variety of applications. Here are some ways Burkert parts for valves can improve their reliability.

Robust design

Burkert valves are designed with durability and reliability in mind. High-quality solenoid valve accessories materials and precise manufacturing processes ensure valves withstand harsh operating conditions, resist wear, and maintain their performance over a long service life.

Modularity and flexibility

Burkert valves are often designed with modularity, allowing flexible configuration and easy integration into various systems. This modularity increases adaptability and simplifies maintenance processes. In the event of a component failure, the modular design allows valve accessories by Burkert to be replaced without disrupting the entire system, reducing downtime.

Application-specific solutions

Burkert technology often provides application-specific valve solutions. Burkert can tailor its valve designs to meet specific needs by understanding the unique requirements of different industries and applications. This approach ensures that the valves are optimized for their intended use, increasing reliability.

The Role of Precision Engineering in System Efficiency

Precision engineering plays a critical role in improving the efficiency of systems in various industries. Precision engineering involves designing, developing, and producing high-precision components and systems that meet specific performance criteria. Let's find out how precision engineering helps improve system efficiency.

Access control

Precision engineering ensures tight tolerances in the manufacturing process, minimizing variations in component dimensions. This level of precision is necessary for complex systems to function correctly.

Optimized performance

Precision components are designed to meet specific performance requirements. This optimization increases overall system efficiency as every part performs at its maximum with minimal waste.

Reduced energy consumption

Systems built with precision components often demonstrate higher energy efficiency. Well-designed parts experience less friction, wear, and heat, lowering energy consumption. This is especially important in industries where energy efficiency is a top priority, such as manufacturing or transportation.

Miniaturization and weight reduction

Precision engineering allows the development of smaller, lighter components without sacrificing performance. This is especially important in the electronics and medical devices industries, where miniaturization is critical. Lighter components also help improve energy efficiency in vehicles.

Increased reliability and durability

Precision engineering ensures that components are manufactured using high-quality materials and processes, increasing reliability and durability. This, in turn, reduces the likelihood of system failures, downtime, and the need for frequent maintenance.

Quality control

Precision engineering emphasizes strict quality control measures throughout the entire manufacturing process. This ensures that each component meets specified standards and operates within the required parameters.

Integration with advanced technologies

Burkert precision components are designed to integrate easily with advanced technologies such as sensors, actuators, and control systems. This integration enhances the overall intelligence and functionality of the system, resulting in increased efficiency and productivity.

Case Studies: Success Stories with Burkert Parts

Burkert has many successful stories of cooperation with other companies. Let's take a look at a few of them.

Revitalization of drinking water treatment in Brockstedt

Bürkert in Menden has tailored the design of oxidation plants to suit a specific application, and they are currently being effectively utilized in each of the three raw water lines. Despite the dynamic nature of water, these units consistently deliver precise aeration dosages under various filter conditions and, notably, at different primary raw water pressures, which may vary significantly based on the operation of the well pumps.

The incorporation of air as needed results in a reduction of compressor runtime, consequently cutting down on energy expenses. A purpose-designed control system prevents over-dosing, eliminates unnecessary resource wastage, and ensures consistent water quality without requiring manual adjustments.

Partnership to develop ALX-009 medical device for home use

Bürkert, specializing in fluid management systems, addressed the specific requirements of Creative Eurecom by creating a tailored solution to outfit the inaugural device capable of producing home remedies for combating lung infections in patients with cystic fibrosis – ALX-009.

One of the two components of ALX-009 possesses a unique high reactivity, thwarting conventional approaches to industrial production and distribution through pharmacies or hospitals. To resolve this challenge, the only viable alternative was to develop a device enabling the preparation of the solution for inhalation at home whenever necessary.

Choosing the Right Burkert Parts for Your System

Choosing the right Burkert parts for your system involves considering several factors to ensure compatibility, functionality, and optimal performance. Here are key considerations to help guide your selection.

System requirements

Determine the specific requirements for your fluid management system. Consider parameters such as fluid type, temperature, pressure, flow rate, and environmental conditions. Understanding your system's needs will help you select Burkert parts that meet those needs.

Application compatibility

Burkert offers a wide range of parts for various applications, including water treatment, pharmaceuticals, food and beverage, chemical processing, and more. Make sure the Burkert parts you select are suitable for your specific application.

Material selection

Evaluate the materials used in Burkert parts based on compatibility with fluid and environmental conditions. Burkert offers parts in materials such as stainless steel, brass, plastic, and special alloys. Select materials that resist corrosion and other forms of degradation that are suitable for your application.

Accuracy requirements

Determine the level of precision and accuracy required for your fluid control system. Burkert is known for its precision engineering, and its parts are designed to provide accurate and reliable measurements. Consider part tolerances, calibration, and accuracy specifications based on your system needs.

Integration with control systems

If your system involves automation and control, ensure Burkert parts can easily integrate with your existing or planned control systems. Burkert offers a range of intelligent technologies that enable connectivity and integration, improving overall system performance and efficiency.

Compliance and certifications

Make sure Burkert parts meet industry standards and regulations for your application. Burkert products often meet international standards and may be certified by ISO, FDA, ATEX, etc. Compliance guarantees the quality and reliability of the parts.

Service and support

Reliable technical support and a responsive service network can be crucial in addressing issues, obtaining information, and ensuring the long-term performance of your system. In addition, the company offers Burkert valve repair kits with spare parts necessary to fix breakdowns.

Budget considerations

While you're making sure the Burkert parts you select meet your system requirements, also consider your budget constraints. Burkert offers a range of solutions at different price points, allowing you to find components that combine performance and economy.