Burkert Sensors

PH/REDOX-electrode for many different types of installations and applications.

Pressure measuring device with an extra-large display.

IN STOCK!!!

Vibrating level switch with tuning fork.

PH/REDOX-electrode for many different types of installations and applications.

Burkert 178716 (00178716) Mass flow controller

- Type of regulator: Mass flow rate

- Mass flow rate range: 0.001 to 10 kg/h

- Hole diameter: 1/8 inch (3.175 mm)

- Body material: AISI 316L stainless steel

Burkert 318040 SideControl NAMUR

- Flow control: The 318040 can control liquid or gas flow with an accuracy of 0.1%.

- Level control: The controller can be used to control the level of a liquid in a tank.

- Temperature control: The controller can be used to control the temperature of a liquid or gas.

- Pressure control: The regulator can be used to control the pressure of a liquid or gas.

Bürkert 416637 Insertion fitting for flow

- Flow rate range: 1666.00 l/min - 51,000 l/min

- Medium temperature: -15.00 °C - 160.00 °C

- Nominal pressure: PN 16

- Roughness of the inner part of the pipe: 1.6 microns

Burkert 418116 Insertion fitting for flow

- Material: stainless steel AISI 316L

- Outer diameter: 1/4 inch (6.35 mm)

- Inner diameter: 1/8 inch (3,175 mm)

- Maximum working pressure: 40 bar

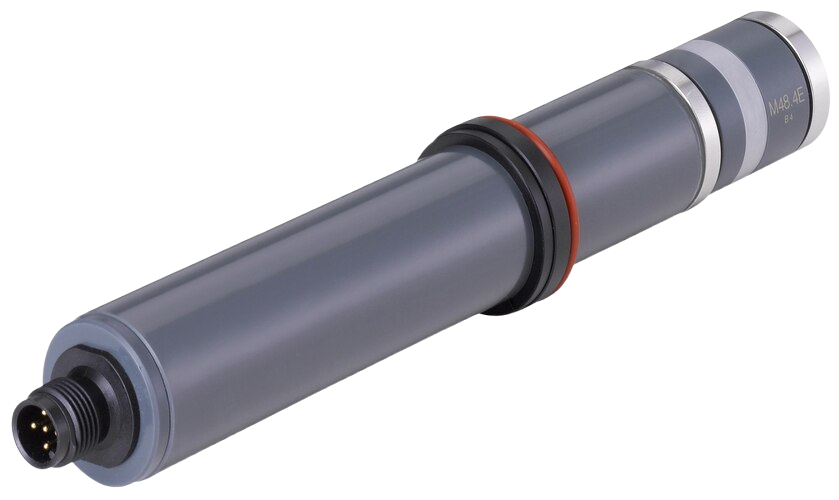

Burkert 418778 Insertion flow sensor

- Sensor type: insertion type

- Flow range: 0.02-50.0 m³/h

- Output: 4-20 mA

- Supply voltage: 24 V DC

- Body: stainless steel

Burkert 418779 Digital flow meter

- Measuring method: turbine

- Measurement range: 0.01-100 l/h

- Measurement accuracy: ±1%

- Operating temperature: -10 to +60 °C

Burkert 427114 electric pH probe

- Measurement Range: pH 0-14,

- ORP -1000 to +1000 mV,

- Temperature Range: -10°C to 60°C,

- Materials: Glass, FKM (fluororubber),

- Connection Type: DN 15-400 mm,

- Integrated Display and Keys for Parameter Programming.

Burkert conductivity transmitter

- High accuracy and stability of measurement results

- Wide measuring range

- Made of high quality materials that ensure durability and reliability

Burkert 567223 Inline flow fitting oval wheel

- High measurement accuracy

- Durability

- Insensitivity to contamination

- Wide temperature range

Burkert 561686 pH/ORP transmitter

- Type: 8202

- Sensor type: pH or ORP

- Temperature range: 0.00°C - 50.00°C

- Output signal: 4-20 mA

- stainless steel, PVC, EPDM, food quality, PVDF

Burkert 561025 pH sensor

- Flow rate measurement,

- 4-20 mA output,

- magnetic paddle wheel.

Advantages: High sensitivity, easy integration, reliable performance.

561670 Burkert Conductivity transmitter

- Flow rate measurement,

- 12-36V,

- 0-100°C,

- paddle wheel/oval gear

Burkert conductivity meter

- Compact size

- Sensitivity: 10 mS/cm

- Operating temperature range: -20 to 80 °C

568523 Burkert Chlorine sensor

- Durable construction: The detector is made of high-quality materials that ensure its durability and reliability.

- Easy to maintain: the detector is easy to install and maintain.

- Cost-effective: the detector has a low operating cost.

Burkert 560547 Integrated flow switch with display

- Flow rate measurement,

- 12-36V,

- 0-100°C,

- paddle wheel/oval gear.

Burkert 566059 Electrolyte for chlorine electrode

- Safety: non-toxic and safe for use in water treatment systems.

- Stability: It is highly resistant to decomposition, so it can be used for a long time.

- Cost-effectiveness: It is economical to use, as it only needs to be changed once every few years.

Burkert flow 5030 pvdf wheel

- Suitable media: Neutral, mildly aggressive, particle-free liquids

- Construction: Inline quarter-turn technology for leak-free operation

Burkert Type 8008 of flow meters is designed for measuring particularly high flow rates and uses the colorimetric measuring principle.

Burkert paddle wheel flow meter

- Linearity: ±0.5% of full scale

- Repeatability: ±0.4% of the measured value

- 4-20 mA output uncertainty: ±0.16 mA

Burkert flow meter 8025

- Pressure range: Up to PN 10

- Measurement tube size: DN 06 to DN 400

Insertion Flow Transmitter

Burkert Sensors: Precision Instrumentation for Industry

Burkert is a German company specializing in fluid control systems and instrumentation. In particular, it produces various industrial sensor solutions for measuring and monitoring liquids. Below, we will discuss these devices in more detail.

The Technology Behind Burkert Sensors

Burkert sensors incorporate various technologies depending on the type of sensor and its intended application. Here are some key technologies commonly found in Burkert sensors.

Flow sensors

Burkert flow sensors measure the flow rate of liquids and gases. Burkert offers a variety of flow sensors suitable for different applications.

Level sensors

Burkert produces sensors that monitor and control liquid levels in tanks or other containers. These sensors can be crucial in industries where precise level control is essential.

Pressure sensors

Burkert pressure sensors are designed to measure the pressure of liquids or gases. Pressure sensors are widely used in industrial processes to ensure optimal operating conditions.

Temperature sensors

Temperature sensors by Burkert are useful for measuring the temperature of fluids in various applications, helping to maintain specific temperature ranges.

Conductivity sensors

These sensors are used to measure the conductivity of a liquid, which can be an important parameter in industries like water treatment or chemical processing.

pH sensors

Burkert manufactures sensors for measuring the pH level of liquids. These are commonly used in industries where a specific pH range is critical.

Applications Across Industries

Burkert sensors for industrial automation find applications across various areas due to their reliability, precision, and adaptability. Here are some common niches where Burkert sensors are often employed.

Automotive manufacturing

- Pressure sensors: Monitor hydraulic systems and other fluid-based processes.

- Flow sensors: Control the flow of coolant and other fluids in manufacturing processes.

- Temperature sensors: Ensure optimal temperatures in various parts of the manufacturing line.

Oil and gas

- Flow sensors: Monitor and control the flow of liquids or gases in pipelines.

- Pressure sensors: Measure and regulate pressure in various oil and gas processing stages.

- Temperature sensors: Ensure proper temperature conditions in refining and processing facilities.

HVAC

- Flow sensors: Monitor fluid flow in heating and cooling systems.

- Temperature sensors: Control and regulate temperatures in HVAC systems.

- Pressure sensors: Monitor pressure conditions in HVAC equipment.

Food and beverage

- Flow sensors: Control the flow of liquids in food processing and beverage production.

- Temperature sensors: Maintain precise temperature conditions during cooking, cooling, and storage processes.

- Pressure sensors: Monitor pressure levels in various stages of production.

Pharmaceuticals and biotechnology

- Flow sensors: Control the flow of liquids in pharmaceutical manufacturing processes.

- Pressure sensors: Ensure optimal pressure conditions in bioreactors and other equipment.

- Temperature sensors: Maintain precise temperature control in pharmaceutical production.

Chemical processing

- pH sensors: Measure and control the acidity or alkalinity of chemical solutions.

- Pressure sensors: Monitor pressure levels in chemical reactors and pipelines.

- Level sensors: Control the levels of liquids in chemical storage tanks.

Water and wastewater treatment

- Level sensors: Used for monitoring and controlling water levels in tanks and reservoirs.

- Flow sensors: Ensure accurate measurement of water flow rates in treatment processes.

- Conductivity sensors: Monitor the conductivity of water to assess its purity.

Selecting the Right Burkert Sensor

Selecting the right Burkert sensor technology involves considering many different aspects that we will discuss below.

- Identify the parameters you need to measure, such as flow, level, pressure, temperature, pH, or conductivity. Choose a sensor specifically designed for the type of measurement required in your application.

- Consider the specific conditions of your application, including the type of fluid, pressure ranges, temperature ranges, and the desired measurement accuracy. Ensure that the sensor specifications align with the requirements of your industrial process.

- Check whether the sensor complies with relevant industry standards and certifications. This is especially important in industries with strict regulatory requirements, such as pharmaceuticals or food and beverage.

- Ensure that the sensor materials are compatible with the measured fluid or substance to avoid corrosion or contamination. Consider the compatibility of the sensor with the overall system and other components.

- Evaluate the environmental conditions where the sensor will be installed. Some sensors are designed for harsh environments, while others may be more suitable for standard conditions.

- Determine the type of output signal required for your control system (e.g., analog, digital, or Fieldbus communication). Check if the sensor is compatible with the communication protocols used in your facility.

Maintenance and Optimization

Maintenance and optimization of Burkert sensors for process control are crucial to ensure their longevity, accuracy, and reliability. Here are some general guidelines you should check.

Maintenance

- Conduct routine visual inspections to check for any physical damage, corrosion, or wear on the sensor housing and components.

- Calibrate sensors periodically to ensure accurate measurements. The calibration frequency depends on the sensor type and the industry/application.

- Keep sensors clean from contaminants that might affect their performance. Use recommended cleaning solutions and methods to avoid damage.

- Check the seals and gaskets regularly to ensure they are intact and functioning properly, especially in applications with aggressive or corrosive media.

- Inspect electrical connections for signs of corrosion or loose wires. Secure any loose connections and clean terminals as needed.

Optimization

- Ensure sensors are installed in optimal locations to capture accurate readings. Consider factors such as fluid dynamics and flow patterns.

- Integrate sensors with control systems for real-time monitoring and automation. Ensure proper communication protocols are used for seamless integration.

- Consider upgrading to newer sensor models or technologies with improved features, precision, or communication capabilities.

- Ensure personnel responsible for sensor maintenance are adequately trained. Knowledgeable staff can identify issues early and perform effective troubleshooting.

- Implement remote monitoring solutions when applicable. This allows you to conduct real-time tracking of sensor performance and facilitates timely intervention in case of issues.