Burkert Solenoid control valves

Burkert 133150 Solenoid valve

- Type: 4/2-position

- Hole diameter: 4 mm

- Connection type: flanged

- Body material: polyamide (PA)

3/2 NC G1/4'' PVDF 230VAC Solenoid Valve

- Model: 0375

- Number of Ways: 3/2

- Voltage: 24V

- Typology: NORMALLY OPEN

burkert proportional solenoid valve

- Regulation Range: 1:200 (for DN 0.8 to 4 mm)

- Hole Diameters: 0.8 - 6 mm

- Seal Material: FKM (Viton)

- Medium: Neutral gases and liquids

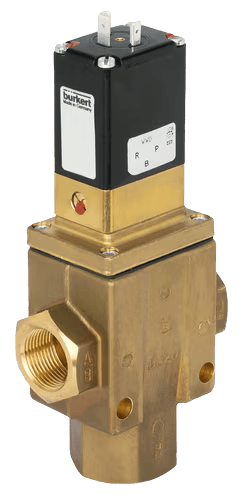

Burkert 2875: Direct-Acting Solenoid Control Valve

- Type 3285

- Item No. 278333

Type 5413 4/2 Way Solenoid Valve Servo-Assisted

Type 5420 4/2 Way Solenoid Valve For Pneumatic

4/2 solenoid valve

- 6519 Solenoid valve 24 VG

- 1/4 Nominal width (details) 8 mm

Solenoid valve with medium separation

Solenoid valve with medium separation

- 6013 Connection: 1/8"

- Number of Ways: 2/2

- Voltage: WITHOUT COIL

- Typology: NORMALLY CLOSED

154541 (00154541)

2836-A-03,0-FF-MS-GM84-024/DC-24

The 2871 Direct Acting Solenoid Valve is used as a control unit in control loops.

Burkert type 2873 is a direct acting 2/2 directional proportional (modulating) solenoid valve used as a regulator in control loops.

Electromotive 2-way globe control valve

Burkert Solenoid Control Valve for: ✓ Water ✓ Fluids ✓ Gas ✓ Steam ✈ Fast shipping ➦ Best Prices! Buy from €73.15 ✦ Check for discounts!

Burkert solenoid control valves are designed to be integrated into pneumatic and hydraulic drive systems and measure the flow of the working medium accurately and reliably. The plastic components offer maximum resistance to corrosion, and the sensitive electromagnetic elements are securely sealed against liquid or gas inside the pipe with seals — ideal for installation in systems transporting corrosive media.

Today we will look closely at the solenoid control valves from Burkert.

What is Burkert Solenoid Control Valves?

Burkert solenoid control valves are devices that provide automatic control of the flow of the working medium on command in the form of an electrical signal: either when it is applied or when it is removed. The principle of operation of a solenoid valve is based on the interaction of a coil, through which an electric current passes, with a metal core - on their relative movement. The shutter connected to the core, moves, opens or closes the direction of the working space.

Benefits of solenoid control valves

Now let's turn our attention to the high-quality solenoid control valves pros:

- Excellent corrosion protection. The solenoid components in the valves are hermetically isolated from the liquid or gaseous medium, thus being protected from corrosion and having a very long service life.

- Manual override with locking option. Each valve has a built-in manual override that may be needed when the pipeline is put into service or during a post-maintenance inspection.

- Wear resistant materials. These solenoid valves are made of wear-resistant plastic with increased resistance to caustic alkaline and acidic solutions.

- Many applications. Due to their corrosion resistance, these solenoid valves are suitable for use in chemical plants, painting and washing, and water treatment.

Burkert Solenoid Valve Types

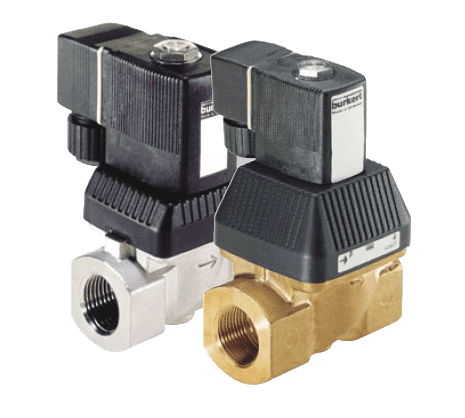

Burkert produces two main types of control valves:

- General-purpose valves control flow rates of both liquids and gases. Versions with large or small coil are available. The housing is made of brass or stainless steel and has an IP65 enclosure rating. Such devices have a ramp function, current control, and Zero point shut-off.

- Motor-driven valves category consists of two series: Type 3280 and 3285. Devices have an actuator that is fully isolated from the main stream. An integrated electric stepper motor acts as such actuator. Presented valves are available in three variants: standard, with positioner and process controller version. A high-pressure version up to 22 bar is also available.

There are also various types of control solenoid valves on the market which we will discuss below:

- The normally closed valve (2/2 NC) has an inlet and outlet in the body. When the solenoid is not energized, the flow is blocked by the main seal, which can be either a diaphragm or a piston. In this mode, the medium flows through a small hole in the diaphragm or piston and helps keep the valve closed. When the solenoid coil is energized, the pilot port opens allowing the medium to exit the cavity above the main seal and open the main valve.

- Normally open direct-acting valve (2/2 NO). With this option, the hole is open, and the working medium is directed from the inlet to the outlet. When voltage is applied, the hole closes. The operation in both cases depends only on the magnetic field generated by the solenoid coil.

- Normally closed valve (2/2 NC) with the positively raised diaphragm, has an inlet and outlet in the body. In these models, the plunger is mechanically attached to the orifice and controls the center pilot port and main seal stroke, allowing it to operate at zero pressure drop.

- Normally closed three-way valve (3/2 NC). With this option, the medium is not passed through the inlet, as the plug is pressed against the seat by a spring. But the medium from the outlet pipeline is discharged through the "exhaust". When connected to the mains, the inlet opens the supply of the working medium, and the "exhaust" closes.

- Normally open three-way valve (3/2 NO). In this version, the hole is open, the working medium is directed from the inlet to the outlet, and the "exhaust" is closed. When connected to the mains, the inlet is closed, and at the same time, the "exhaust" is opened and connected to the outlet pipeline. In both cases, the operation depends only on the magnetic field generated by the solenoid coil.

Control solenoid valves by Burkert primarily have fast response time, excellent sensitivity and repeatability of results. You can buy Burkert control valve at the best price at Eltra-Trade company.