Burkert Solenoid Valves

IN STOCK!

6213-EV-A10,0AAMSGM83-6-024/DC-10

In Stock!!!

A-normally closed, inlet port 1 (P/NC), 1,20 mm (3/64 inch)

IN STOCK!!!

0470-C-04,0-BB-FM01-TA22-024/UC-02 *

Normally open, brass body, suitable for various pneumatic applications.

IN STOCK!!!

00164579 2000-B-2-20,0-EE-VA-SA93-C-D *AF93+NK51

IN STOCK!!!

6213-EV-A13,0BBMSGM84-5-024/50-08

IN STOCK!!!

Actuator for 2/2-way angle seat valve, 25mm (1")

burkert solenoid valve 24vdc are high-tech devices used to precisely control the flow of liquids and gases in various industrial processes. These valves are characterized by high reliability, durability and a wide range of applications.

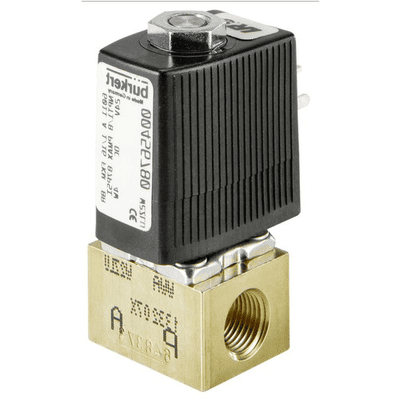

The Burkert 0127 direct-acting 2/2 or 3/2 -way solenoid valve is designed for aggressive and clean gases and liquids with low flow rates and pressures from vacuum to 2 bar.

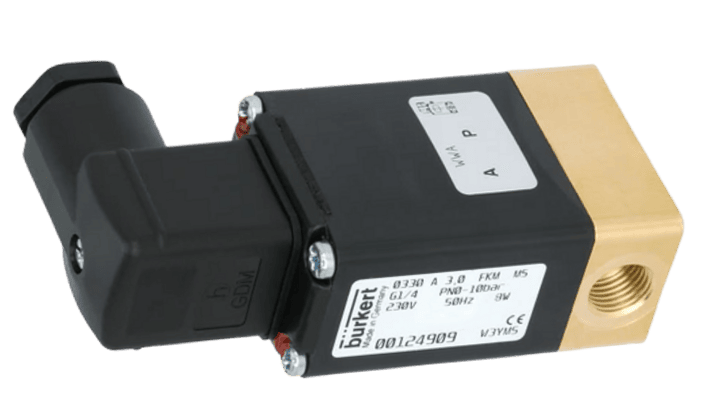

3 2 way solenoid valve are electromechanical devices used to control the flow of fluids (liquids or gases) in various industrial applications.

Valve 0331 is a direct acting pendulum valve with medium isolation.

Available in 2/2-way or 3/2-way.

burkert piston valve

Burkert type 6223 is 2/2-way proportional solenoid valves

Servo-assisted 3/2-way piston valve

Burkert 120680 2-way solenoid valve

- Type: 2/2-way

- Size: 1.5 mm

- Working pressure: 0-2 bar

- Type: usually closed

Bürkert 120721 2/2-position solenoid valve

- Type: 2/2-position

- Action: direct

- State in the absence of voltage: closed

Burkert 125317 Solenoid valve

- Valve type: 2/2

- Mode: normally closed

- Body: AISI 316L stainless steel

- Actuator: electromagnet

Burkert 133150 Solenoid valve

- Type: 4/2-position

- Hole diameter: 4 mm

- Connection type: flanged

- Body material: polyamide (PA)

Bürkert 136307 2/2-way solenoid valve

- Valve type: 2/2-way

- Thread: G1/4''

- Coil: 24V DC

- Body material: PP

Burkert 160737 Rotary angle valve

- Type of valve: Rotary angle

- Number of positions: 2

- Hole diameter: 1 inch (25 mm)

- Body material: AISI 316L stainless steel

Burkert angle seat valve

2/2 - A - normally closed

Burkert 178859 Valve

- Valve type: 2/2-position angle valve

- Control signal: pneumatic

- Body material: brass (gun metal)

- Sealing material: PTFE

Bürkert 184566 3/2-way pneumatic valve

- Type: 3/2-way

- Diameter: 10 mm

- Operating mode: normally closed

- Material: polyamide (PA)

Bürkert 187072 2/2-way butterfly valve

- Suitable for use with steam

- Has a high throughput

- Has a long service life

- Easily integrates with Bürkert's ELEMENT automation units

Burkert 189860 Valve

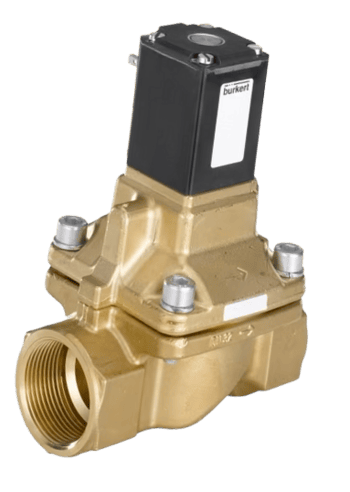

- Valve type: 2/2-way, servo-driven

- Nominal diameter: 25 mm (1 inch)

- Maximum working pressure: 25 bar

- Body material: brass

Burkert 20037306 3/2-way solenoid valve

- Dimensions: diameter 8 mm (3/8 inch)

- Maximum pressure: 16 bar (232 psi)

- Maximum temperature: 150 °C (302 °F)

Bürkert 20293 Solenoid valve 2/2-way

- Body material: brass.

- Connection type: internal thread G1/4.

- Power supply voltage: 24 V DC.

- Sealing material: FKM (fluoroplastic).

- Operating temperature range: 0-90 °C.

Burkert 210892 2/2-way solenoid valve

- The valve body is made of brass and the diaphragm is made of NBR (nitrile rubber).

- The valve has 1/2" NPT fittings. NPT, which allows it to be connected to standard pipelines.

- The valve has an operating pressure of up to 10 bar and an operating temperature of -10 to 80 degrees Celsius.

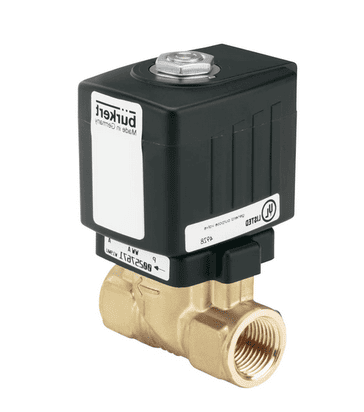

Burkert solenoid valves are electromechanically operated systems for regulating the flow of liquids or gases.

Burkert Solenoid Valve Types

Company produces two main types of solenoid units, depending on the operation principle:

- direct acting or

- servo-assisted.

Burkert releases the following categories of solenoid valves:

- General purpose 2/2 is a valve category with dual ports. They have the simplest and the most reliable flow control mechanism.

- General purpose 3/2 is a valve type with 3 ports and 2 flow paths in their design. This is the most popular model in distribution systems.

- Water Solenoid is a unit that specifically designed for work with the water flow. Its main features are hygiene and tightness. Such products can work with drinking water.

- Hazardous Location valves are designed for operating in the harsh and aggressive environments. They conform all requirements of the basic certificates: ATEX, IECEx, EAC, NEPSI etc.

- Steam solenoid valves are created for work with steam flow. Company manufactures piston and plunger variants.

- High-pressure valves perform work in conditions with high pressure. It is available as direct-acting plunger or servo-assisted piston type.

- Cryogenic valves are created for work at very low temperature ranges. Such devices work with both gases and liquids.

- Media separated valves will be good solution for aggressive and contaminated conditions.

- Burkert solenoid valves are the famous standard of reliability and manufacturability in the modern World. This is achieved due to the vast experience of the Company in the field of fluid control automation.

How does a Burkert solenoid valve work?

What is a solenoid valve? By design, a solenoid valve is no different from a simple valve of a standard shut-off valve. A solenoid in this case means "electrical". The only difference is in the way it is controlled - it is implemented in automatic mode and involves remote action on the shut-off device.

Like any element of shut-off valves, the solenoid valve is housed in a body. The rugged metal body of the product is made of cast iron or brass. Modern shut-off elements are also often equipped with a body made of high-strength polymers. As such material can be nylon and traditional polypropylene. The valve covers are also made of the same materials.

In addition to the body, the Burkert solenoid valve includes the following components:

- coil;

- plug;

- stem;

- spring;

- plunger;

- fastener;

- diaphragm.

The main driving element of the valve is the diaphragm designed as a piston. The solenoid coil acts as the main device on the basis of which the automatic control of the shut-off element is realized. The valves are called solenoid valves because the plungers and rods present in their design are made of magnetic materials.

The device is used in different fields, which determines the diversity of its types. There is Burkert solenoid valve catalog:

- direct action - the solenoid, when voltage is applied directly, changes the position of the diaphragm, i.e., it opens or closes the valve, maintaining the power of the solenoid used, which allows virtually no limit on the diameter of the passage opening and the value of the recommended pressure in the pipe;

- indirect action - when voltage is applied, they act on the other (non-electromagnetic) valve, losing power, so they operate only at minimum (close to zero) pressure drop;

- open and closed - change the position of the stem under-voltage to open or closed;

- bistable - pulses of alternating polarity are required for operation, so they operate only with a DC power supply. No voltage to the coil is required to hold open or closed position;

- battery-operated - they switch with a brief application of a voltage of a certain polarity;

- for low-pressure systems - operate with the direct current;

- AC operated - allow a stronger electromagnetic field to overcome pressure loads on the diaphragm.

- gas and water shutoff valves typically use 220 volt AC current. The resulting power ensures the reliability and safety of the system.

The design of the apparatus ensures its tightness. A magnetic core is located inside the solenoid coil tube. When the coil receives a signal from a sensor or controller, the core retracts inside and opens the valve. Burkert solenoid valve distributors offer products in several variations, which can be chosen according to the actual needs of the buyer.

What is a solenoid valve used for?

Typically, modern irrigation or spraying systems used in the home as well as in industrial applications have a remote control. This means that the operator no longer has to go over and manually unscrew the lever of the machine every time. It is enough just to press a button on the remote control and the faucet will automatically open or close to let water into the system. A separate advantage of solenoid valves is that they can be set on a timer. That is, the irrigation system can be pre-programmed to operate at a certain point in time, after which the solenoid valve Burkert will shut off the fluid supply to the system.

Continuously regulating elements are electromagnetic proportional valves designed to control the flow of gases or liquids with an adjustable level of the input signal. You have the opportunity to buy products by contacting the company Pneumoelement, whose catalog contains an extensive range of products.

The vast majority of models function on and off. They are either fully closed or fully open. If the electric current at the inlet varies, it is possible to regulate smoothly. In other cases, the fluid flow will be continuous. Therefore, all varieties of devices are divided into conventional devices and those equipped with an electric actuator. The latter category includes elements equipped with powerful and high-precision stepper motors.

Their power is redistributed to the actuator, which makes it possible to carry out a gradual opening. Such devices are used in electronic equipment in medical and analytical devices. They work with cooling circuits, burners, fuel systems where dosing of substances is required, as well as with compact process controllers. The products are characterized by accuracy and stability. They are economical, compact, fast reacting, and have a long service life. Burkert solenoid valve price can be very profitable. High-quality, robust products are actively used not only in businesses but also in the home.