Eltra Encoder Optical hollow shaft incremental encoders

IN STOCK!

- Size: 80 mm

- With zero pulse

- Resolution: 1024 ppr

IN STOCK!

IN STOCK!

- through hollow shaft

- optical

- with spring

IN STOCK!

Blind hollow shaft incremental encoder

- 1024 ppr

- 5 ... 28 V DC

- Bore diam. 10mm

IN STOCK!

Incremental miniaturized kit encoder.

- Encoder size 30M

- Without zero pulse

- Resolution: 500 ppr

IN STOCK!!!

Hollow shaft incremental Encoder.

IN STOCK!

Resolition 256 PPR

Ø80 encoder

Incremental encoder

- Size: 80 mm

- Without zero pulse

- Resolution: 1024 ppr

IN STOCK!

Incremental Encoder Eltra with through hollow shaft, 49 mm, 1024 ppr.

IN STOCK!!!

Blind hollow shaft miniaturized incremental encoder for general application. With stator coupling. Encoder size 38 mm. Without zero pulse. Resolution: 100 ppr.

IN STOCK!!!

Incremental encoder

IN STOCK!!!

10000 ppr, with zero index, 5/28V, Push Pull

IN STOCK!

SIZE 19-01

IN STOCK!

Variant with extended operational range and enhanced durability.

IN STOCK!

- 80 mm size

- 14 mm bore

- 2048 ppr

- 5 - 28 V DC

IN STOCK!

IN STOCK!

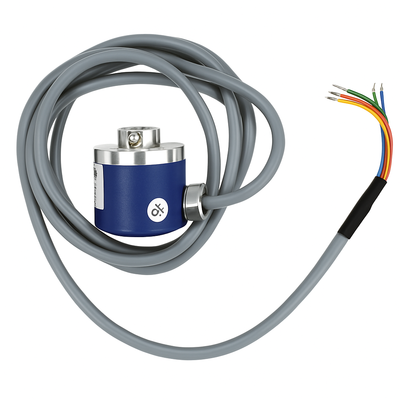

High accuracy, 1024 pulses/revolution, radial cable output, durable and reliable.

IN STOCK!

Incremental encoder

Optical Hollow Shaft Incremental Encoder

Incremental encoder

Hollow Shaft Incremental Encoders

Hollow shaft encoder technology includes a rotary encoder with a hollow opening in its center. This design allows the encoder to be directly mounted onto a rotating shaft without additional couplings or adapters. The hollow shaft provides space for the shaft of the machine or equipment to pass through the encoder, making it a compact and convenient solution for various applications. Below, we will discuss hollow shaft encoders in detail.

Types and Variations of Hollow Shaft Incremental Encoders

Hollow shaft incremental encoders come in various types and designs to cater to different applications and requirements. Here are some common hollow shaft incremental encoder types.

Direct hollow shaft encoders

Such equipment has a hollow bore from the beginning, allowing it to be directly mounted onto the rotating shaft of a motor or other machinery. Direct hollow shaft encoders eliminate the need for additional couplings or adapters.

Through hollow shaft encoders

These encoders have a bore that extends through the entire encoder. This design allows for a more straightforward installation, as the machinery shaft can pass through the encoder. It is beneficial in scenarios where space is a critical factor.

Hub shaft encoders

In hub shaft encoders, the encoder is mounted on a hub surrounding the shaft. The hub may have a hollow space or an opening through which the shaft passes.

Magnetic hollow shaft encoders

Some hollow shaft encoders use magnetic technology for position sensing. They employ magnetic sensors and markers for incremental encoding.

Optical hollow shaft encoders

Optical shaft encoders use light and sensors to generate signals. Optical hollow shaft encoders are designed with this technology, offering precise and reliable position feedback.

Miniature hollow shaft encoders

In applications with minimal space, miniature hollow shaft encoders are designed to provide compact solutions while maintaining accuracy.

Industrial-grade hollow shaft encoders

These encoders are built to withstand harsh industrial environments, often featuring robust designs to resist dust, moisture, and vibrations.

Explosion-proof hollow shaft encoders

In environments with a risk of explosion, such as in specific industrial settings, explosion-proof hollow shaft encoders are designed to meet safety standards and prevent the ignition of explosive gases or dust.

Applications of Optical Hollow Shaft Incremental Encoders

Optical incremental encoders find applications in various industries and systems where precise and real-time position feedback is crucial for control and automation. Here are some applications of incremental optical hollow shaft encoders.

The engine control unit

Hollow shaft encoders are often used in motor control applications, especially where the encoder needs to be mounted directly onto the motor shaft. This includes applications such as servo motors, stepper motors, and other types of electric motors.

Robotics

Robotic systems use incremental hollow shaft encoders to provide accurate feedback on the position and movement of robotic joints. This is critical to ensuring precise and controlled robot movements when performing tasks such as assembly and welding.

Industrial automation

These encoders are vital in various industrial automation systems, providing feedback for position control in conveyor systems, packaging equipment, and other automated manufacturing processes.

CNC machines

Computer numerical control (CNC) machine tools, such as milling machines and lathes, use incremental hollow shaft encoders to provide precise feedback on the position of tool heads, allowing precise machining operations.

Printing and labeling machines

Such devices are integrated into printing and labeling machines and precisely position print heads and label applicators. This is important to maintain print quality and alignment.

Textile equipment

In the textile industry, hollow shaft encoders are used in spinning machines, weaving machines, and knitting machines to monitor and control the position of various components, ensuring the quality and consistency of textile production.

Medical equipment

Such encoders find applications in medical devices and equipment such as robotic surgical systems and diagnostic machines. They provide feedback for precise control and positioning during medical procedures.

Renewable energy

In wind turbines, hollow shaft encoders are used to control the position and speed of the turbine blades, allowing for efficient and controlled energy production. They are also employed in solar energy tracking systems to optimize the orientation of solar panels.

Material handling systems

They play an essential role in material handling systems, including conveyor belts and crane systems, where precise positioning is critical to transport materials efficiently and safely.

Automotive production

On automotive assembly lines, hollow shaft encoders are used for tasks such as monitoring the position of robotic arms, controlling the movement of vehicles on production lines, and ensuring precise component placement.

Considerations for Selecting Hollow Shaft Incremental Encoders

Selecting the suitable incremental hollow shaft encoder for a specific application involves carefully considering various factors to ensure compatibility, accuracy, and reliability. Here are vital considerations.

- Ensure that the encoder's hollow shaft diameter matches the shaft size it will be mounted on.

- Verify the shaft type (solid or hollow) and choose an encoder compatible with your system.

- Determine the required resolution based on the precision needed in your application. Higher resolution provides finer position feedback.

- Evaluate the mounting options and compatibility with your equipment. Different hollow shaft encoders may have various mounting configurations, such as hub, through-hole, or flange mounting.

- Consider the available space for installation. Hollow shaft encoders are chosen for their compact design, but ensuring they fit within the available space is essential.

- Check the environmental specifications, including temperature range, humidity resistance, and IP rating. Choose an incremental shaft encoder that can withstand the conditions of your operating environment.

- Determine the electrical interface of the encoder (TTL, HTL, or others) based on compatibility with your control system. Also, consider signal levels and wiring requirements.

- Verify the maximum speed and frequency capabilities of the encoder. Ensure they meet or exceed the requirements of your application, especially if it involves high-speed machinery.

- Decide whether an incremental encoder is suitable for your application or if you need an absolute position encoder. Incremental encoders provide relative position information, while absolute encoders provide absolute details.

- Consider the level of vibration and shock the encoder will experience in your application. Choose an encoder with appropriate resistance to ensure reliable operation in such conditions.

- Verify that the encoder's power supply voltage matches the requirements of your system. Ensure compatibility to prevent damage and ensure proper functioning.

- Take into account the physical dimensions and weight of the encoder. Ensure that it does not add excessive load to the rotating shaft and that it can be accommodated within the design constraints of your system.

- If your application has unique requirements, check whether the manufacturer offers customization options, such as special shaft sizes or additional features.