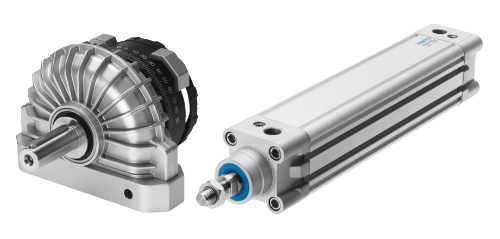

Festo Classic Cylinders

Festo AEVC

| Mode of operation | Pushing - Single-acting |

| Piston diameter | 12 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 61.5 N |

| Stroke | 5 mm |

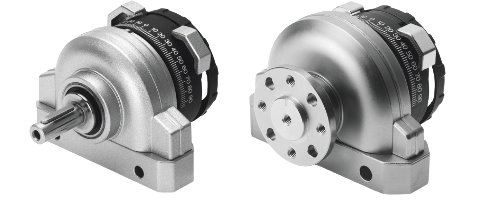

Festo DSR

| Size | 40 |

| Theoretical torque at 0.6 MPa (6 bar, 87 psi) | 20 Nm |

| Swivel angle | 0 deg - 180 deg |

Festo DSR

| Size | 10 |

| Theoretical torque at 0.6 MPa (6 bar, 87 psi) | 0.5 Nm |

| Swivel angle | 0 deg - 180 deg |

Festo DSR

| Size | 12 |

| Theoretical torque at 0.6 MPa (6 bar, 87 psi) | 1 Nm |

| Swivel angle | 0 deg - 180 deg |

Festo DSR

| Size | 16 |

| Theoretical torque at 0.6 MPa (6 bar, 87 psi) | 2 Nm |

| Swivel angle | 0 deg - 180 deg |

Festo DSR

| Size | 25 |

| Theoretical torque at 0.6 MPa (6 bar, 87 psi) | 5 Nm |

| Swivel angle | 0 deg - 180 deg |

Festo DSR

| Size | 32 |

| Theoretical torque at 0.6 MPa (6 bar, 87 psi) | 10 Nm |

| Swivel angle | 0 deg - 180 deg |

Festo DSR

| Size | 12 |

| Theoretical torque at 0.6 MPa (6 bar, 87 psi) | 1 Nm |

| Swivel angle | 0 deg - 180 deg |

Festo DSR

| Size | 25 |

| Theoretical torque at 0.6 MPa (6 bar, 87 psi) | 5 Nm |

| Swivel angle | 0 deg - 180 deg |

Festo DSR

| Size | 32 |

| Theoretical torque at 0.6 MPa (6 bar, 87 psi) | 10 Nm |

| Swivel angle | 0 deg - 180 deg |

Festo DSR

| Size | 40 |

| Theoretical torque at 0.6 MPa (6 bar, 87 psi) | 20 Nm |

| Swivel angle | 0 deg - 180 deg |

Festo WSR

When it comes to pneumatic systems, cylinders are essential in process automation to ensure smooth movement and high precision in operations. Festo is a global leader in pneumatics, offering solutions that meet the highest industrial requirements. One of the most sought-after products is the Festo classic cylinders, which are highly reliable, robust, and versatile for various industrial applications.

These cylinders combine innovative technology with proven solutions, making them ideal for use in the most demanding production environments. In this article, we will examine their features and benefits, and why they are a great choice for your business.

Key Features and Performance Specifications

When choosing pneumatic cylinders, it is important to consider their technical parameters and how they meet your requirements. Festo automation cylinders have various characteristics that make them universal for diverse tasks. One of the main advantages of the cylinders is the high degree of precision, which is achieved through high-quality materials and innovative design solutions.

You should also pay attention to parameters such as the diameter and stroke of the cylinder, which vary depending on the model and can be adapted to the specific needs of your production. For example, the diameter can be from 12 to 320 mm, which allows the cylinders to be used in different areas, from light applications to heavy industry. In addition, the cylinders are equipped with a damping system, which ensures smooth and quiet operation.

It is important to note that Festo cylinders are designed for maximum efficiency with minimal energy consumption. This means that you will not only get a high-quality product but also be able to reduce operating costs due to low air consumption. As a result, you will improve productivity while maintaining a competitive advantage.

Durable and Reliable Design for Industrial Applications

The durability of cylinders is one of the most important factors you need to consider when choosing cylinders for your production lines. Classic cylinders from Festo are designed to last a long time, even in the most demanding and aggressive conditions. This is especially important for companies operating in heavy industry, where equipment is exposed to high loads and mechanical stress.

The durability of the cylinders is ensured by the use of high-quality materials, such as anodized aluminum and stainless steel, which protect the devices from corrosion and other external factors. Thus, the cylinders do not lose their properties in conditions of high humidity, dust, or chemical exposure. Therefore, if your company needs reliable solutions for harsh operating conditions, Festo cylinders will be the optimal choice.

In addition, the design of the cylinders was developed with ease of maintenance and easy repair in mind. This means that you can quickly and inexpensively replace worn parts, which significantly reduces equipment downtime and increases the overall productivity of your production.

Types of Festo Classic Cylinders

Festo offers a wide range of cylinders to suit a wide range of applications. Each type of industrial motion control Festo cylinder has its own unique characteristics and operational advantages.

Single-Acting and Double-Acting Cylinders

Festo single-acting cylinders operate by applying air pressure to only one side, returning to their original position under the influence of a spring or external force. These cylinders are often used in applications where one-way motion is required. They are ideal for simple tasks and save energy by using minimal air.

On the other hand, double-acting cylinders operate by applying air to both sides of the piston, allowing movement in both directions. These cylinders are versatile and are used in more complex automated systems where maximum flexibility and control over motion are required.

Compact and Round Cylinders

Festo compact cylinders are a great solution when space on your production line is limited. Their main advantage is their small dimensions, which allow them to be integrated into equipment with minimal installation space requirements. Despite their compact size, such cylinders have high performance and can withstand significant loads.

Festo round cylinders, on the other hand, are characterized by their simple design and versatility. You can use them in a wide range of industrial applications while ensuring reliable operation under high-intensity conditions. These cylinders are suitable for both standard tasks and more specific applications due to their robustness and lightness.

Advantages of Festo Classic Cylinders

Festo cylinders have many advantages that make them an ideal choice for various industries. Let's find out what benefits you can get using industrial motion control cylinders from Festo.

High Precision and Control

One of the main advantages of Festo cylinders is their precision. In particular, they are designed to provide maximum control over movement, which is especially important when you need to perform precision operations. For example, if your business is related to manufacturing, where a high degree of precision is required, such cylinders will be an excellent choice.

Long-Lasting Performance in Harsh Environments

Festo cylinders boast a long service life even under the most difficult operating conditions. In fact, their robust design and use of high-quality materials allow them to operate reliably and without failure in aggressive environments. This means that you can count on reliable operation of the equipment for many years.

Easy Integration with Automation Systems

Festo cylinders are easy to integrate with modern automation systems, allowing you to seamlessly integrate them into your existing production processes. This is especially important for companies that want to automate their lines and increase productivity without spending significant time on retooling their equipment.

Why Choose Festo Classic Cylinders from ELTRA TRADE

The choice of pneumatic cylinders is an important decision, on which the efficiency of your production depends. Eltra Trade offers you the perfect combination of price and quality that Festo provides. The company offers a wide range of cylinders for a variety of applications, guaranteeing their compliance with high quality and durability standards. In fact, for you, cooperation with Eltra Trade is not only an opportunity to purchase high-quality cylinders but also to receive professional advice on their selection and installation. Therefore, if you are looking for a reliable supplier of pneumatic equipment, contacting Eltra Trade will be the right decision for your business.