Festo Classic Valves

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 1400 l/min |

| Pneumatic connection, port 1 | G1/4 |

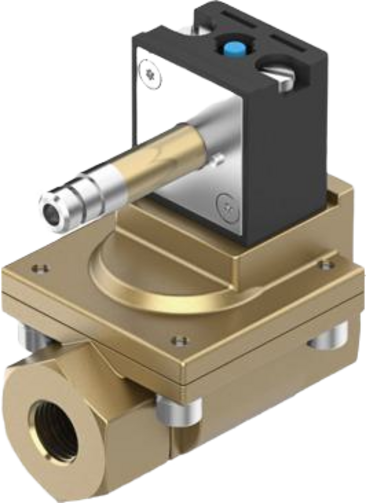

| Design | Diaphragm valve |

| Valve function | 2/2-way, closed, monostable |

| Connection Process valve | G1/2 |

| Standard nominal flow rate (standardised to DIN 1343) | 3100 l/min |

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 1600 l/min |

| Pneumatic connection, port 1 | G1/4 |

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 1600 l/min |

| Pneumatic connection, port 1 | G1/4 |

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 1000 l/min |

| Pneumatic connection, port 1 | G1/8 |

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 2000 l/min |

| Pneumatic connection, port 1 | G3/8 |

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 1600 l/min |

| Pneumatic connection, port 1 | G1/4 |

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 1000 l/min |

| Pneumatic connection, port 1 | G1/8 |

| Valve function | 5/2-way, monostable |

| Standard nominal flow rate (standardised to DIN 1343) | 1300 l/min |

| Pneumatic connection, port 1 | G1/4 |

| Valve function | 5/2-way, monostable |

| Standard nominal flow rate (standardised to DIN 1343) | 750 l/min |

| Pneumatic connection, port 1 | G1/8 |

| Valve function | 5/2-way, monostable |

| Standard nominal flow rate (standardised to DIN 1343) | 2000 l/min |

| Pneumatic connection, port 1 | G3/8 |

| Valve function | 5/3 exhausted |

| Standard nominal flow rate (standardised to DIN 1343) | 1600 l/min |

| Pneumatic connection, port 1 | G1/4 |

| Valve function | 5/3 exhausted |

| Standard nominal flow rate (standardised to DIN 1343) | 1000 l/min |

| Pneumatic connection, port 1 | G1/8 |

| Valve function | 5/3 closed |

| Standard nominal flow rate (standardised to DIN 1343) | 1600 l/min |

| Pneumatic connection, port 1 | G1/4 |

| Valve function | 5/3 closed |

| Standard nominal flow rate (standardised to DIN 1343) | 1000 l/min |

| Pneumatic connection, port 1 | G1/8 |

| Valve function | 5/3 closed |

| Standard nominal flow rate (standardised to DIN 1343) | 2200 l/min |

| Pneumatic connection, port 1 | G3/8 |

| Design | Diaphragm valve |

| Valve function | 2/2-way, closed, monostable |

| Connection Process valve | G1 |

| Standard nominal flow rate (standardised to DIN 1343) | 11500 l/min |

| Design | Diaphragm valve |

| Valve function | 2/2-way, closed, monostable |

| Connection Process valve | G1/4 |

| Standard nominal flow rate (standardised to DIN 1343) | 2000 l/min |

| Design | Diaphragm valve |

| Valve function | 2/2-way, closed, monostable |

| Connection Process valve | G3/4 |

| Standard nominal flow rate (standardised to DIN 1343) | 10000 l/min |

| Design | Diaphragm valve |

| Valve function | 2/2-way, closed, monostable |

| Connection Process valve | G3/8 |

| Standard nominal flow rate (standardised to DIN 1343) | 2900 l/min |

| Valve function | 5/2-way, monostable |

| Standard nominal flow rate (standardised to DIN 1343) | 1300 l/min |

| Pneumatic connection, port 1 | G1/4 |

| Valve function | 5/2-way, monostable |

| Standard nominal flow rate (standardised to DIN 1343) | 750 l/min |

| Pneumatic connection, port 1 | G1/8 |

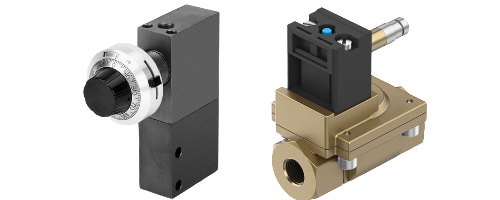

| Valve function | 5/2- or 3/2-way monostable |

| Standard nominal flow rate (standardised to DIN 1343) | 900 l/min |

| Pneumatic connection, port 1 | G1/4 |

Festo classic valves are reliable solutions for precisely controlling air, liquid, and gas flows. These products combine innovation, practicality, and durability, making them the ideal choice for industrial automation flow control.

You can trust these valves to handle the most demanding tasks, knowing they will provide stable operation and high productivity. In particular, Festo offers a wide range of classic valves suitable for both standard and specific requirements.

Indeed, choosing Festo valves means that you will get quality and the certainty of long-term operation. These solutions allow you to minimize the risk of downtime and maximize the productivity of your equipment.

Key Features and Technical Details

Festo classic valves are designed to be used in a wide range of applications. Thanks to high-quality materials and a well-thought-out design, they demonstrate exceptional reliability and high efficiency. Durable and wear-resistant materials allow you to use the valves even in difficult environments. At the same time, proportional control ensures precise flow control, which is especially important in production processes with high demands on precision.

In addition, thanks to their compact dimensions, many Festo valve models are ideal for installation in confined spaces. In fact, you can adapt them to any conditions, minimizing installation and maintenance costs.

Durable Construction for Long-Term Reliability

Festo valves are made from materials that are resistant to corrosion and aggressive media. This ensures their stable operation even in conditions of high humidity, dust, or extreme temperatures. You can trust these valves in intensive use, knowing that they will maintain their efficiency over a long period. In addition, the durability of the equipment will help you reduce the overall costs of maintenance and replacement of components. Thus, the robust design of Festo valves becomes an important element in increasing the reliability of your production.

Categories of Festo Classic Valves

In fact, you can choose the right Festo valve based on the specifics of your production. The wide range allows you to adapt the equipment to various tasks, whether it is the control of pneumatic automation systems or precise flow regulation.

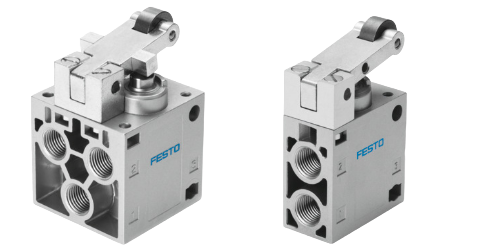

Pneumatic Control Valves for Automation

These valves, such as Festo valves for pneumatic systems, are designed to control air flows in automated processes. You will be able to use them in industrial installations where high reaction speed and stability of operation are important. Indeed, their use helps you optimize processes, improving resource allocation and increasing equipment productivity.

Directional and Proportional Flow Valves

These solutions, including directional and proportional control valves, are ideal for precise regulation of air or liquid flow. You can use them in applications that require constant pressure and stable flow. Specifically, directional valves provide easy adjustment and quick adaptation to different tasks. This makes them a sought-after solution for automation where flexibility is important.

Benefits of Festo Classic Valves

Indeed, Festo classic valves have a number of advantages that will help you improve the efficiency of your processes. Let's find out what exactly.

Precise and Reliable Flow Regulation

Classic valves provide high flow control accuracy, which is especially important in industrial processes where the stability of parameters affects the overall efficiency of the system. For example, you will be able to regulate the supply of air or other media with minimal deviations, which will increase the productivity of the equipment and reduce the risk of errors. Such reliability makes them indispensable in systems with high precision requirements.

Sturdy Design for Demanding Industrial Applications

In fact, strength and durability are the basis of the design of Festo valves. Thanks to the use of high-quality materials such as stainless steel and aluminum alloys, the valves withstand long-term loads and aggressive operating conditions. You can successfully use them in production workshops where equipment is exposed to high temperatures, humidity, or chemicals.

Easy Integration into Automation Systems

What will be useful for you specifically is that Festo valves can be easily integrated into existing pneumatic and automation systems. This means that you do not need complex equipment modifications or lengthy personnel training. For example, modern connection interfaces allow you to connect valves to controllers or other components in just a few minutes.

High Energy Efficiency

Energy consumption of equipment is an important aspect in the context of rising resource prices. Festo classic valves are designed to minimize air leakage and the energy spent on flow control. This way, you can reduce operating costs without compromising productivity.

Flexibility in Setting Operating Parameters

In particular, you will appreciate the ability to customize the valves to the individual needs of your production. For example, adjustable models allow you to change the flow rate or pressure depending on the current task. This significantly increases the versatility of the valves and their adaptation to specific conditions.

Typical Applications of Festo Classic Valves

Festo classic valves solutions are used in a wide range of industries, ensuring stable and efficient system operation.

Controlling Pneumatic Systems

Festo classic valves are widely used to control airflow in pneumatic systems. This allows you to efficiently regulate the movement of actuators such as cylinders or manipulators, ensuring stable operation of the equipment.

Enhancing Industrial Automation Processes

In particular, with Festo valves, you can increase the accuracy and speed of automated processes. This is especially true in areas such as assembly lines, where high-quality operations are required.

Supporting Material Handling and Robotic Systems

Indeed, Festo valves are indispensable in robotics and automated material handling systems. For example, they ensure precise positioning and control of robotic manipulators, which increases productivity and reduces errors.

Use in Air Conditioning and Ventilation Systems

Classic valves are ideal for controlling air flows in HVAC systems. You can set the optimal parameters to maintain a comfortable microclimate in buildings and production facilities.

Applications in the Pharmaceutical and Food Industry

Specifically, in these industries, valves with a robust design and the ability to control the flow of liquids or gases are highly valued. This allows you to meet strict safety and quality standards.

Water Treatment and Supply Systems

For example, Festo valves can be used to control water flows in filtration or distribution systems. Their corrosion resistance and durability make them an ideal choice for such applications.

Why Purchase Festo Classic Valves from ELTRA TRADE

Eltra Trade offers you reliable solutions that will help optimize production processes and increase their efficiency.

Premium Automation Solutions

You will have access to valves that combine advanced technology and high reliability, which is important for achieving maximum efficiency.

Extensive Product Selection for Varied Needs

The company offers compact Festo classic valves, as well as other models that are suitable for any task.

Global Support and Reliable Delivery Services

Eltra Trade ensures prompt delivery of products, allowing you to minimize equipment downtime and continue working without delays. Thus, choosing Festo classic valves through Eltra Trade is a guarantee of quality, reliability, and durability.