Festo Control technology and remote I O

Festo CPX

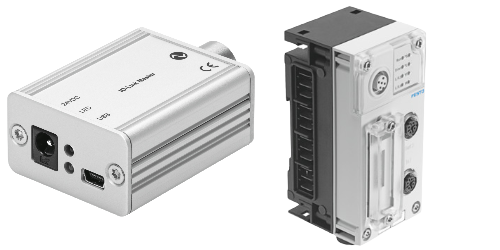

Festo CDSB

Festo CDSU

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX

Festo CPX-AP-I

Festo CPX-AP-I

Festo CPX-AP-I

Festo CPX-AP-I

Festo CPX-AP-I

Festo CPX-AP-I

Festo CPX-AP-I

Festo CPX-AP-I

Festo CPX-AP-I

Festo CPX

If you work in the industrial sector, you will sooner or later be faced with the need to continuously optimize your production processes. In such circumstances, Festo control technology and remote I/O systems are essential for ensuring high productivity and flexibility. In practice, this means increased efficiency and improved quality in production operations.

Festo Remote I/O systems are designed to provide you with simple and reliable control of complex production processes. Remote I/O systems allow you to connect sensors and actuators to centralized or distributed controllers. This is especially important for large production facilities where multiple data points need to be managed. Indeed, the use of these technologies opens up the possibility of implementing scalable solutions that can be adapted to your specific needs.

Festo technology is highly integrated with various communication protocols, making these systems universal for use in various industries. For example, if you need to connect several controllers to one network, Festo systems ensure smooth data transfer as well as the ability to flexibly control production processes.

Key Features and Benefits

One of the main features of Festo I/O systems is the ability to distribute control. This means that you can organize production control over significant distances without losing productivity and accuracy. Specifically, this approach significantly simplifies the automation process, reducing the requirements for central data processing. In addition, an important feature is the flexibility of the input-output system. Using IO control, you can connect various devices and sensors while maintaining a single data transfer format. In fact, this significantly reduces the time for setting up equipment and its subsequent operation.

Finally, it is worth noting the scalability of solutions. As your business grows, control IO systems easily adapt to new requirements without the need for a complete replacement of equipment. Thus, it allows you to avoid additional costs for purchasing new systems and upgrading current ones.

Efficient Integration for Industrial Automation

To effectively integrate remote control technology into industrial automation processes, the equipment must support modern communication standards. Festo offers exactly such solutions. Thanks to the integration with cloud services and the use of modern industrial protocols, you can monitor your production processes in real time, no matter the distance from the facility.

For example, remote I/O modules can be integrated with existing machine control systems to increase the efficiency of your equipment. This allows you to improve control over production lines, reduce downtime, and increase overall productivity. Thus, using solutions from Festo allows you to monitor every stage of the process, improving both the speed and quality of production operations. This is a key factor if you are striving for maximum automation.

Types of Festo Control Technology and Remote I/O Systems

Festo offers a wide range of industrial automation solutions, including programmable logic controllers and remote I/O modules. Each of these systems is designed to solve specific problems at different stages of the production process. In the next section, we will take a closer look at how PLCs and remote I/O modules work.

Programmable Logic Controllers (PLC)

PLCs are the heart of most automation systems. They provide centralized control of production processes and can be programmed to perform complex tasks. Festo PLCs in particular have high performance and support a wide range of interfaces for connecting external devices.

Remote I/O Modules for Distributed Control

Remote I/O modules allow control to be distributed across several nodes, which is especially important for large production facilities. Festo remote I/O can be integrated into any existing control system and allows various parameters to be monitored locally without increasing the load on the central processor.

Advantages of Using Festo Control and I/O Systems

Festo remote I/O for automation and offers significant advantages for the control of production processes. First of all, they ensure seamless communication between devices and help to increase the overall efficiency of the enterprise. Let's take a closer look at these advantages.

Seamless Communication Between Devices

One of the main advantages of using Festo control and I/O systems is reliable and seamless communication between all connected devices. You get stable data transfer, which is especially important for the smooth functioning of production processes. In particular, such systems reduce the likelihood of errors and minimize equipment downtime.

Enhanced Process Control and Monitoring

Remote control technology systems from Festo ensure high accuracy of process control and allow you to monitor key parameters of production lines in real time. This, in turn, improves monitoring and control at every stage of production. For example, you can quickly make changes to equipment settings or respond to critical situations.

Scalable Solutions for Complex Automation

Festo control technology offers scalable solutions for complex automation, enabling you to increase production capacity without having to completely modernize the control system. In this context, scalability is one of the key factors when choosing solutions for large-scale production.

Reliability and Durability

Festo control systems are renowned for their high reliability, which is especially important for companies where even short-term failures can lead to significant losses. These systems are designed to operate in the harshest conditions, ensuring trouble-free operation for many years.

Ease of Operation and Configuration

With their intuitive interface and easy configuration, Festo control systems allow users to quickly adapt to new equipment. This minimizes the time required for employee training and commissioning, which is especially important for the rapid start-up of new production lines.

Energy Saving and Cost-Effectiveness

Festo control technologies are designed with energy-saving requirements in mind, which significantly reduces operating costs. Optimizing equipment operation with advanced control systems helps reduce energy consumption, which has a positive impact on overall production profitability.

Common Applications of Festo Control Technology

Festo remote IO technologies are used in various industries. These systems are designed to meet the needs of modern production and can be used in a wide variety of conditions. Below are the main areas in which you can use the company's solutions.

- Automotive industry. Technological solutions that Festo offers you are widely used in the control of robotic assembly lines, where high precision and speed of operations are important.

- Food industry. Festo control systems are used to automate packaging processes and product quality control.

- Chemical and pharmaceutical industries. Here, strict control over technological processes is important, which Festo successfully provides.

- Logistics and warehouses. Machine control systems help automate warehouse processes, speeding up work with goods and reducing the human factor.

- Energy sector. In the energy sector, Festo solutions are used to control complex distribution networks and equipment.

Why Choose Festo Control Technology from ELTRA TRADE

When you choose Festo control systems, it is important to find a reliable supplier who will provide you with high-quality equipment and full technical support. Eltra Trade offers you high-quality solutions, integration with existing systems, as well as qualified technical support at all stages of the project. In addition, we cooperate directly with Festo, which allows you to get the most favorable conditions for the purchase of equipment. We also have a well-established logistics chain, which means that your order will arrive at its destination as quickly as possible. Therefore, by choosing us, you invest in reliable technologies and confidence that your project will be implemented professionally.