Festo Guided Cylinders

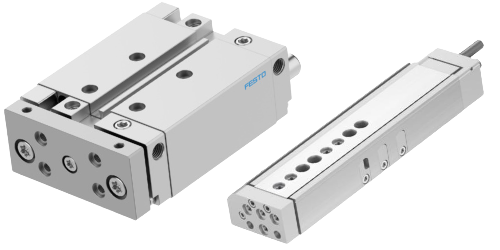

Festo DFM

| Piston diameter | 25 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 295 N |

| Stroke | 50 mm |

| Cushioning | Pneumatic cushioning, adjustable at both ends |

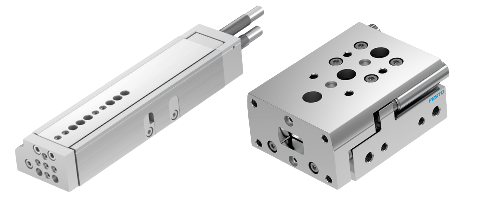

Festo DGSL

Festo DFM

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188 N |

| Stroke | 50 mm |

| Cushioning | Pneumatic cushioning, adjustable at both ends |

Festo DFM

| Piston diameter | 32 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 482 N |

| Stroke | 50 mm |

| Cushioning | Pneumatic cushioning, adjustable at both ends |

Festo DGSL

| Piston diameter | 12 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 68 N |

| Stroke | 30 mm |

| Cushioning | Progressive shock absorber at both ends |

Festo DGSL

| Piston diameter | 12 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 68 N |

| Stroke | 50 mm |

| Cushioning | Progressive shock absorber at both ends |

Festo DGSL

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 121 N |

| Stroke | 50 mm |

| Cushioning | Progressive shock absorber at both ends |

Festo DGSL

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188 N |

| Stroke | 100 mm |

| Cushioning | Progressive shock absorber at both ends |

Festo DGSL

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188 N |

| Stroke | 150 mm |

| Cushioning | Progressive shock absorber at both ends |

Festo DGSL

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188 N |

| Stroke | 50 mm |

| Cushioning | Progressive shock absorber at both ends |

Festo DGSL

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188 N |

| Stroke | 80 mm |

| Cushioning | Progressive shock absorber at both ends |

Festo DGSL

Festo DGSL

| Piston diameter | 25 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 295 N |

| Stroke | 200 mm |

| Cushioning | Progressive shock absorber at both ends |

Festo DGSL

| Piston diameter | 25 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 295 N |

| Stroke | 80 mm |

| Cushioning | Progressive shock absorber at both ends |

Festo DGSL

| Piston diameter | 10 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 47 N |

| Stroke | 80 mm |

| Cushioning | Elastic cushioning rings/plates at both ends |

Festo DGST

| Piston diameter | 10 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 94 N |

| Stroke | 20 mm |

| Cushioning | Elastic cushioning rings/plates at both ends |

In the world of industrial automation and mechanical engineering, the use of high-quality equipment is the basis for the successful and smooth operation of production processes. One of these indispensable components are Festo guided cylinders, which ensure precise movement, stability, and durability of the equipment. If you are looking to increase the efficiency and reliability of production systems, Festo guided cylinders may be the right solution for you.

As a manufacturing professional, you probably understand how important it is to choose the right components for automated systems. In particular, guided cylinders ensure high-precision movement and stability under heavy loads. This is the reason why many companies choose solutions from Festo.

Main Features and Technical Specifications

Festo offers you a wide range of guide cylinders, each designed to meet the specific requirements of different industries. Whether you need precision in tight spaces or stability under high loads, Festo guided pneumatic cylinders offer you the optimal solution. The main characteristics of such cylinders are high strength, low friction and minimal wear losses, which ensures long-term operation without the need for frequent maintenance.

In addition, many Festo cylinder models are equipped with a speed control option, allowing you to adjust the movement to your requirements. This is especially important if your process requires high precision or varies depending on the characteristics of the materials being processed. In this case, Festo guided cylinders offer the ideal solution for motion control.

Durable and Precise Design for Industrial Use

When it comes to working under heavy loads and high precision requirements, it is important to choose components that can withstand extreme conditions. Festo cylinders are designed with these factors in mind and feature a robust design that not only protects against external influences but also guarantees stable operation throughout their entire service life. As a result, your systems will operate reliably and without failures.

You can be sure that by choosing a Festo cylinder guide, you will receive a product that copes with tasks even in the most difficult production conditions. These cylinders are designed with all requirements for stability and precision in mind, making them ideal for use in industrial lines where high reliability is required.

Variations of Festo Guided Cylinders

Festo offers different types of guide cylinders, allowing you to choose the most suitable option for your needs. Depending on the requirements of the production process, you can choose compact or heavy-duty models that are ideal for your purposes. Let's take a closer look at them.

Compact Guided Cylinders for Limited Spaces

If your system operates in a space-constrained environment, you should consider Festo compact cylinders. These cylinders are specifically designed for use in environments where space is limited but high precision is required. Compact guided cylinders provide precise motion control and minimize the space required for installation, making them ideal for use in smaller production lines.

So, by using compact cylinders, you will save space and improve the overall efficiency of your processes. Using such solutions will allow you to easily integrate them into existing systems without changing the basic design.

Heavy-Duty Guided Cylinders for High-Load Capacities

When it comes to heavy-duty applications and the need to withstand high loads, the Festo guided cylinder can be a reliable solution for you. The heavy-duty models of these cylinders can handle heavy loads and ensure stable movement even under the toughest conditions. Such cylinders are the ideal choice for use in heavy-duty production lines where high load capacity and stability are required. Specifically, the use of such cylinders will allow you to increase productivity without the risk of equipment overload. Thanks to the reinforced design, such models have a long service life and minimal maintenance costs.

Advantages of Festo Guided Cylinders

When you choose precision motion control cylinders from Festo, you get reliable components and a host of benefits that make them convenient and efficient to use. It's time to learn more about them.

Superior Stability and Accuracy

One of the main advantages of Festo guided cylinders is their high stability and precision. Precision guided cylinders are designed to exacting standards, allowing you to achieve the best results in motion control. Such cylinders ensure smooth and precise movement, which is especially important when performing tasks that require high precision. Thus, using Festo cylinders allows you to be sure that each operation is carried out with maximum precision, which reduces the risk of errors and defects on the production line.

Durable Performance in High-Load Applications

When your production process requires high loads, the components must withstand these conditions over time. Festo solutions offers durable cylinders that maintain their performance even under high loads. This means that you can count on stable operation throughout the entire service life of the cylinder. In addition, these cylinders require minimal maintenance, which reduces operating costs and increases overall efficiency.

Seamless Integration with Automation Systems

Another significant advantage is the ability to seamlessly integrate Festo cylinders into existing automated systems. You can easily configure and implement guided cylinders from Festo into your system without the need for significant changes to the infrastructure. This makes the implementation process quick and simple. Thanks to this, you can increase the productivity of your automated lines without spending a lot of time on upgrading equipment.

Typical Applications for Festo Guided Cylinders

Festo guide cylinders can be found in a variety of industries. Regardless of the specifics of your business, these cylinders will help you improve productivity and achieve greater efficiency in process automation.

Systems for Material Handling and Positioning

One of the most common applications of guide cylinders is their use in material handling and positioning systems. They provide precise and stable movement of loads, making them indispensable for processes that require high precision.

Use in Packaging and Assembly Lines

In particular, Festo guide cylinders are often used in packaging and assembly lines. They help to optimize assembly and packaging processes, making them faster and more efficient.

Integration in Robotics and Automated Systems

In automated systems and robotics, Festo cylinders ensure precise and reliable movement, which is especially important when performing complex manipulations and operations. Their high precision makes them indispensable for use in robotic lines.

Automotive Applications

Festo cylinders play an important role in the automotive industry, especially in assembly and handling processes for heavy parts. They ensure the precise positioning of components during installation and welding, which is especially important for maintaining the quality and safety of the final product.

Food Industry Applications

In the food industry, not only precision and reliability are important, but also the hygiene of the equipment. Festo guided cylinders can be used in production lines for packaging, filling, and handling food products.

Pharmaceutical Applications

In pharmaceutical production, precision and reliability are crucial, as even the slightest error can lead to significant consequences. Festo cylinders are ideal for applications that require high precision and control.

Why Festo Guided Cylinders from ELTRA TRADE are the Best Choice

If you are looking for a reliable supplier of automation components, Festo motion control solutions will be your ideal choice. First of all, the company offers only certified equipment, which guarantees its compliance with all quality standards. In addition, Eltra Trade provides fast delivery and technical support, which allows you to receive the necessary components in the shortest possible time and quickly implement them in your systems.