Festo Hand operated Valves

| Standard nominal flow rate (standardised to DIN 1343) | 16 l/min |

| pneumatic working port | PK-3 |

| Valve function | 3/2-way, closed, monostable |

| Standard nominal flow rate (standardised to DIN 1343) | 50 l/min |

| Nominal size | 1.5 mm |

| pneumatic working port | PK-3 |

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 750 l/min |

| Pneumatic connection, port 1 | G1/8 |

| Operating pressure | -0.95 bar - 10 bar |

| Valve function | 3/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 750 l/min |

| Pneumatic connection, port 1 | G1/8 |

| Operating pressure | -0.95 bar - 10 bar |

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 1200 l/min |

| Pneumatic connection, port 1 | G1/4 |

| Operating pressure | -0.95 bar - 10 bar |

| Valve function | 3/2-way, monostable, open/closed |

| Standard nominal flow rate (standardised to DIN 1343) | 750 l/min |

| Pneumatic connection, port 1 | G1/8 |

| Operating pressure | -0.95 bar - 10 bar |

| Valve function | 3/2-way, monostable, open/closed |

| Standard nominal flow rate (standardised to DIN 1343) | 750 l/min |

| Pneumatic connection, port 1 | G1/8 |

| Operating pressure | 3.5 bar - 10 bar |

| Valve function | 4/3 closed |

| Standard nominal flow rate (standardised to DIN 1343) | 1500 l/min |

| Pneumatic connection, port 1 | G1/4 |

| pneumatic working port | G1/4 |

| Valve function | 4/3 closed |

| Standard nominal flow rate (standardised to DIN 1343) | 1150 l/min |

| Pneumatic connection, port 1 | G1/4 |

| pneumatic working port | G1/4 |

| Valve function | 4/3 closed |

| Standard nominal flow rate (standardised to DIN 1343) | 600 l/min |

| Pneumatic connection, port 1 | G1/8 |

| pneumatic working port | G1/8 |

| Valve function | 3/2-way, single solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 750 l/min |

| Pneumatic connection, port 1 | G1/8 |

| Operating pressure | -0.95 bar - 10 bar |

If you are involved in industrial automation, you certainly understand the importance of effective control of air or fluid flows. Festo hand-operated valves are reliable and versatile solutions that will help you achieve maximum precision and process stability. These devices are ideal for use in environments where direct operator intervention is required.

In fact, Festo hand-operated valves stand out for their ease of use, high durability, and long service life. You can implement them in your system without complex settings, and their compact and ergonomic design will save space and ensure ease of use. That is why valves in this category are popular among professionals working in areas such as pneumatic systems, robotics, and material handling. In this review, we will take a detailed look at the characteristics, benefits, and applications of hand-operated valves to help you choose the most suitable option for your task.

Main Features and Benefits

Specifically, Festo manual control valves are designed to meet strict quality standards and meet the requirements of most industrial processes. Key features include a robust, wear-resistant design and compact dimensions, making them an ideal choice for tight spaces.

One of the most significant advantages is the high control precision. You will be able to regulate the flow of air or liquid manually, which is especially important in processes where automation is not possible or requires additional costs. In addition, such valves have a wide operating temperature range, so they can be used in high humidity and high or low temperatures. This truly makes them universal solutions for a wide range of tasks.

Reliable Manual Solutions for Industrial Systems

In demanding applications, you can rely on Festo mechanical control valves, which demonstrate impressive resistance to mechanical stress. These valves are designed to withstand tough conditions such as high pressure or constant vibrations. Indeed, reliability and durability are the main qualities that distinguish Festo products. You will receive equipment that can operate in tough conditions without the need for frequent maintenance or repair.

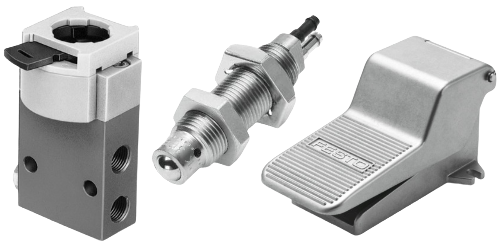

Variants of Festo Hand-Operated Valves

Festo offers you a wide range of manual valves that can be adapted to the specific tasks of your system. Festo valves for pneumatic systems demonstrate a high level of versatility, so you can choose the model that best suits your requirements.

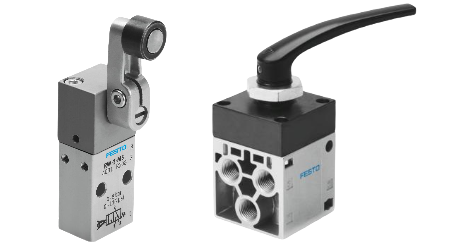

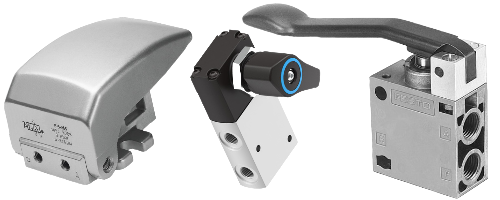

Valves with Lever Control Mechanisms

Manual toggle valves for automation give you precise and smooth flow control. These valves are easy to operate and efficient. They are designed to require minimal force to activate, reducing operator strain. You will also appreciate the robustness of toggle valves, which retain their properties even after repeated use. These devices are ideal for demanding industrial environments.

Push-Activated and Toggle Valve Options

For example, push-button flow control valves provide operational process control. You can quickly turn on or off flows, which is especially important in situations that require an instant response. This type of valve is widely used in production lines and automated systems where manual and automatic control must be combined.

Key Benefits of Festo Hand-Operated Valves

Festo manual flow control valves are becoming an excellent choice for systems where automation may be redundant or where local control is required. You can easily integrate them into your processes, increasing the overall efficiency of the equipment. Let's take a closer look at what exactly makes them so popular.

Effortless and Accurate Flow Management

The sophisticated design of Festo valves allows you to easily control the flow of air or liquid. This helps ensure the stable operation of the equipment, which is especially important in tasks that require precise control. For example, in pneumatic systems, such control helps maintain optimal pressure, reducing the likelihood of errors and deviations. This makes the valves a convenient choice for a wide range of industrial processes.

Designed for Tough Industrial Conditions

In difficult industrial conditions, equipment is subject to significant loads, which requires high stability. Festo manual flow control valves are specially designed for such tasks. Indeed, these devices are resistant to high temperatures, humidity, as well as chemically active environments. You can use them in systems with aggressive external factors without worrying about premature failure.

Affordable and Efficient Manual Alternatives

If you are looking for a cost-effective yet functional solution, Festo mechanical control valves are a great choice. These devices are an affordable alternative to automated systems, not inferior to them in terms of reliability and ease of use. You will be able to reduce equipment and maintenance costs while maintaining high efficiency of production processes. This is especially important for companies seeking to optimize their budgets without losing quality.

Compact Design

One of the significant advantages of Festo manual valves is their compact design. This allows you to easily integrate them even into limited spaces without creating additional complications. This way, you get equipment that fits perfectly into your system, ensuring ease of installation and operation.

Practical Uses of Festo Hand-Operated Valves

Festo manual control valves are used in a wide range of applications. Their versatility allows you to solve a wide range of tasks, from airflow control to integration into complex automation systems. Whether you are looking for reliable manual control valves for local control or want to complement an automated system, Festo manual control valves provide the optimal solution.

Managing Pneumatic Systems

Pneumatic systems require precise and reliable control of air flows, which ensures stable operation of the equipment. Using Festo manual flow control valves, you can achieve high performance in your systems. In particular, such valves are easy to use, they can be easily integrated into pneumatic installations, ensuring long-term stability and reliability of operation.

Regulation of Industrial Processes

For example, in dosing or liquid supply tasks, such valves will help you maintain a constant flow, minimizing deviations. This is important for precise industrial operations, such as the production of chemical mixtures or the control of hydraulic systems. This way, you can optimize processes, increasing their productivity and reducing the number of errors.

Integration in Robotics and Material Flow

Modern production lines increasingly include elements of robotics and automated material handling. Festo manual valves are ideal for such tasks due to their versatility and reliability. You get equipment that easily integrates into your system, improving process control and increasing their overall efficiency.

Why ELTRA TRADE is the Best Choice for Festo Hand-Operated Valves

When you are going to choose a supplier for equipment, it is important to consider the quality of the products as well as the level of service. Eltra Trade is a reliable partner that will help you solve any problems related to the selection, purchase, and maintenance of Festo manual valves.

Top-Tier Products Tailored for Precision

Eltra Trade offers you only original Festo hand-operated valves that meet the highest quality standards. In fact, by choosing this store, you can be sure that you will receive equipment that meets your requirements.

Extensive Selection of Valve Solutions

In particular, the company's range includes a variety of models, including Festo mechanical control valves and push-button flow control valves, which are suitable for a wide range of systems. You can choose a solution that fits perfectly into your infrastructure.

Dedicated Global Assistance and Quick Delivery

Indeed, Eltra Trade provides you with a wide range of products and comprehensive services. You will be able to take advantage of professional consultations, prompt delivery, and technical support, which will ensure the smooth operation of your equipment.