Festo Hydraulic Dampers

Festo DYSC

| Stroke | 12 mm |

| Max. energy consumption per stroke | 10 J |

Festo YSR-C

| Stroke | 8 mm |

| Max. energy consumption per stroke | 3 J |

Festo DYSC

| Stroke | 5 mm |

| Max. energy consumption per stroke | 1 J |

Festo DYSC

| Stroke | 5 mm |

| Max. energy consumption per stroke | 2 J |

Festo DYSC

| Stroke | 8 mm |

| Max. energy consumption per stroke | 3 J |

Festo DYSR

| Stroke | 20 mm |

| Max. energy consumption per stroke | 32 J |

Festo DYSR

| Stroke | 40 mm |

| Max. energy consumption per stroke | 160 J |

Festo DYSW

| Stroke | 17 mm |

| Max. energy consumption per stroke | 8 J |

Festo DYSW

| Stroke | 20 mm |

| Max. energy consumption per stroke | 12 J |

Festo DYSW

| Stroke | 6 mm |

| Max. energy consumption per stroke | 0.8 J |

Festo DYSW

| Stroke | 8 mm |

| Max. energy consumption per stroke | 1.3 J |

Festo DYSW

| Stroke | 10 mm |

| Max. energy consumption per stroke | 2.5 J |

Festo DYSW

| Stroke | 14 mm |

| Max. energy consumption per stroke | 4 J |

Festo YSR-C

| Stroke | 10 mm |

| Max. energy consumption per stroke | 6 J |

Festo YSR-C

| Stroke | 12 mm |

| Max. energy consumption per stroke | 10 J |

Festo YSR-C

| Stroke | 20 mm |

| Max. energy consumption per stroke | 30 J |

Festo YSR-C

| Stroke | 25 mm |

| Max. energy consumption per stroke | 60 J |

Festo YSR-C

| Stroke | 40 mm |

| Max. energy consumption per stroke | 160 J |

Festo YSR-C

| Stroke | 60 mm |

| Max. energy consumption per stroke | 380 J |

Festo YSR-C

| Stroke | 5 mm |

| Max. energy consumption per stroke | 1 J |

Festo YSR-C

| Stroke | 5 mm |

| Max. energy consumption per stroke | 2 J |

Festo YSRW

| Stroke | 17 mm |

| Max. energy consumption per stroke | 8 J |

Festo YSRW

| Stroke | 20 mm |

| Max. energy consumption per stroke | 12 J |

Festo YSRW

| Stroke | 26 mm |

| Max. energy consumption per stroke | 35 J |

Festo YSRW

| Stroke | 10 mm |

| Max. energy consumption per stroke | 2.5 J |

Festo YSRW

| Stroke | 14 mm |

| Max. energy consumption per stroke | 4 J |

Festo YSRW-DGC

Festo YSRW-DGC

Festo YSRW-DGC

Festo YSRW-DGC

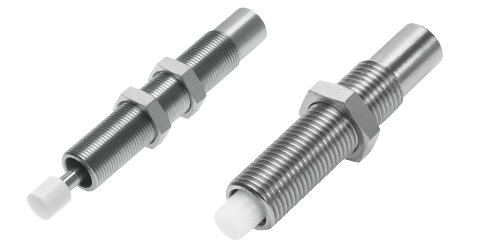

Hydraulic dampers play an important role in the industry, providing reliable absorption of shocks and vibrations, which helps to extend the service life of the equipment and improve its performance. Festo hydraulic dampers are high-tech components designed to minimize wear and increase the stability of production systems. If you are looking to improve the reliability and safety of your production lines, hydraulic dampers from Festo may be just what you need.

You will appreciate the benefits of these dampers when you see how effectively they reduce vibrations and soften shocks in a variety of applications. In particular, the use of Festo hydraulic dampers eliminates unwanted vibrations, ensuring smooth operation of equipment and improving overall productivity.

Key Features and Performance Specifications

Festo hydraulic dampers have a number of characteristics that make them popular in industrial processes. They are designed to operate under high load conditions, which allows them to cope with intensive operating conditions. Thanks to their well-thought-out design, Festo small hydraulic dampers can be used even in confined spaces, while still providing high performance.

These dampers are designed to minimize the impact force by redistributing energy and effectively absorbing vibrations. In fact, linear hydraulic dampers Festo work with precision and reliability, which reduces the risk of equipment damage and significantly increases its service life. Thus, the use of such dampers in systems allows you to avoid breakdowns and reduce repair and maintenance costs.

In addition, Festo offers dampers that can be easily integrated into existing automation systems. These Festo solutions guarantee smooth and reliable operation of all equipment, which is an important advantage for modern production.

Advanced Design for Energy Absorption and Vibration Control

Festo creates dampers that not only withstand high loads but also have an advanced design that ensures high-quality energy absorption. This means that industrial hydraulic dampers from Festo reliably redistribute impact energy, reducing vibration levels and ensuring stable operation of the equipment. You can significantly improve the efficiency of your production processes using such solutions for motion and vibration control.

Specifically, Festo hydraulic dampers help you maintain the stability of your production line even under intense loads. Thanks to this, you can be sure of the durability and reliability of your equipment.

Types of Festo Hydraulic Dampers

Festo offers various types of hydraulic dampers suitable for a wide range of manufacturing applications. Whether you are looking for high-speed hydraulic dampers for automation or heavy-duty models, Festo has a solution for your application.

Adjustable Hydraulic Dampers

Festo adjustable hydraulic dampers are the ideal choice when you need precise adjustment of the damping level. These dampers allow you to control the speed and strength of absorption, making them a versatile solution for various industrial processes. Using these dampers, you can adjust their operation to the requirements of your equipment, which ensures optimal protection and smooth operation. For example, when using these dampers in automated systems, you will have precise control over the damping process, which helps reduce wear and extend the service life of the equipment.

Fixed Hydraulic Dampers for Specific Applications

Festo fixed hydraulic dampers are designed for use in systems that require constant damping without the possibility of adjustment. These dampers ensure the stable operation of the equipment, reducing the load on its components and protecting against breakdowns. Such solutions are especially effective in conditions where constant vibration absorption is required. Using fixed dampers, you can optimize the operation of the equipment in conditions where constant protection against vibrations is required, which is especially important for heavy production lines.

Advantages of Festo Hydraulic Dampers

With Festo vibration management systems, you will benefit from a number of advantages that will increase the efficiency and reliability of your equipment. These dampers are specially designed for use in harsh conditions, allowing you to count on the durability and stability of all production lines.

Extended Lifespan of Industrial Equipment

Using Festo hydraulic dampers significantly increases the service life of the equipment. Due to the effective absorption of vibrations and the redistribution of impact energy, you can protect equipment from wear and tear and extend its service life.

Simple Integration into Existing Systems

You can easily integrate Festo hydraulic dampers into existing systems. Thanks to their sophisticated design and compatibility standards, you can install the dampers without the need for complex modifications to the equipment.

Increased Wear Resistance

With Festo heavy-duty industrial dampers, you get components that are highly resistant to wear. This is especially important in intensive use, where equipment is subject to high loads and vibrations. Such dampers will provide you with stable operation and minimize the need for frequent maintenance.

Reduced Noise and Vibration

Festo hydraulic dampers effectively reduce noise and vibration levels on the production line. Thanks to this, you can create more comfortable conditions for personnel and reduce the load on the equipment, extending its service life.

Maintaining System Stability

Festo dampers help maintain the stability and smooth operation of production systems. Using hydraulic dampers will allow you to be sure that production processes are carried out with high precision and without failures.

Improved Process Safety

Using Festo hydraulic dampers will improve the safety of equipment operation. Minimize the risk of breakdowns and accidents, which increases the overall safety of your production processes.

High-load Capability

These dampers are specially designed for heavy-duty applications. They withstand intense shocks and vibrations, allowing you to use them in heavy-duty industrial environments.

Increased Efficiency of Production Processes

Festo hydraulic dampers allow you to optimize your workflow by ensuring smooth movement of machinery and reducing the risk of sudden stops. You will have more opportunities for stable and efficient operation of your equipment, which will have a positive impact on productivity and reduce time costs.

Minimize Maintenance Costs

With Festo hydraulic dampers, you can reduce your regular maintenance costs. These dampers minimize wear on your equipment, allowing you to replace parts less often and reduce repair costs. This makes your production costs more predictable and manageable.

Common Applications for Festo Hydraulic Dampers

Festo motion control solutions are used in various industries where reliable protection of equipment from vibrations and shocks is required. Regardless of the specifics of your industry, hydraulic dampers will help you improve production processes and increase overall efficiency.

Mechanical Engineering

In mechanical engineering, Festo hydraulic dampers help control vibrations, reduce stress on components, and prevent wear. By using these dampers, you can extend the service life of your equipment and reduce repair costs.

Automotive Industry

The automotive industry makes extensive use of hydraulic dampers to ensure stability and safety in production processes. Festo hydraulic dampers allow you to control the movement and protect components on production lines.

Food Industry

In the food industry, hygiene and reliability of equipment are important. Festo hydraulic dampers are used on packaging and filling lines, ensuring stability and smooth operation of the equipment.

Robotics and Automated Systems

These hydraulic dampers are widely used in automated systems and robotics. They help you ensure precise motion control and protect equipment from wear.

Heavy Industry

For heavy industry, where equipment operates under high loads, industrial dampers are the ideal solution for protection against vibrations and shocks.

Textile Industry

In the textile industry, Festo dampers help to maintain stable material flow and prevent damage to equipment.

Assembly and Positioning Systems

Festo hydraulic dampers are used in assembly and positioning systems where precision and control of movements are important. With these dampers, you can increase the accuracy of operations and reduce wear on components.

Why Choose Festo Hydraulic Dampers from ELTRA TRADE

If you are looking for reliable hydraulic dampers suppliers, then Eltra Trade is the partner you need. The company offers a wide range of Festo hydraulic dampers that meet the highest quality standards. You will be able to choose dampers that are ideal for your equipment, whether it is production, packaging, or assembly. In fact, when purchasing Festo hydraulic dampers from Eltra Trade, you will receive high-quality products and professional advice that will help you choose the best solution for your business.