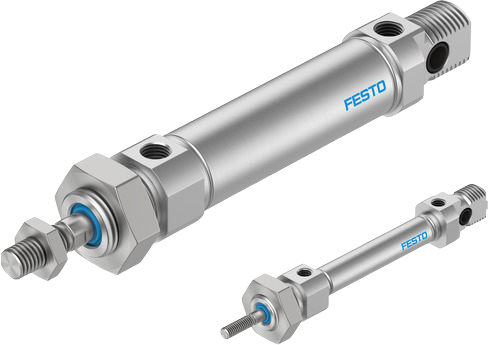

Festo Round Cylinders

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 100 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 150 mm |

Festo DSNU

Festo DSNU

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 10 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 125 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 150 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 160 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 200 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 25 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 40 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 50 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 60 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 16 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 120.6 N |

| Stroke | 80 mm |

Festo DSNU

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 100 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 125 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 160 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 200 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 25 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 250 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 30 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 300 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 320 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 40 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 50 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 20 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188.5 N |

| Stroke | 80 mm |

Festo DSNU

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 25 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 294.5 N |

| Stroke | 10 mm |

Festo DSNU

| Mode of operation | Double-acting |

| Piston diameter | 25 mm |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 294.5 N |

| Stroke | 100 mm |

Festo round cylinders occupy a special place among pneumatic equipment because they offer high reliability and versatility. They are designed for use in a variety of areas, from small automated lines to large industrial systems. If you want to optimize production processes, such cylinders will be an excellent choice due to their robustness, efficiency, and ability to work in difficult conditions.

Indeed, round cylinders have a compact design, which allows them to be used even in limited spaces. You can use them in systems with a high equipment density without sacrificing productivity. In fact, such cylinders are considered a universal solution for most automation tasks.

In particular, the company's products, like Festo round cylinders, are designed to meet the needs of modern production processes. Their reliability and durability will help you minimize operating costs and ensure the stability of the equipment.

Key Features and Technical Specifications

When you select cylinders for your equipment, the right characteristics are very important. Festo pneumatic round cylinders are characterized by high precision, durability, and the ability to work in a wide range of conditions. You can use them both at high and low temperatures, making them a versatile choice for a wide range of industries.

Specifically, their working pressure range allows you to flexibly configure the system depending on your needs. Moreover, Festo round cylinders provide smooth and stable operation thanks to their carefully thought-out design. These characteristics make them ideal for applications that require precise motion control.

For example, you can use compact industrial cylinders to automate processes that require compactness and functionality. Their design allows them to withstand high loads without reducing efficiency. In addition, the materials used in the cylinders are corrosion-resistant, which guarantees their durability even in aggressive environments.

Compact Design for Versatile Applications

One of the main advantages of compact round cylinders is their compactness. You can integrate them into equipment even with limited space, which is especially important for modern production systems. In fact, these cylinders are ideal for tasks where every detail matters to you, be it assembly, packaging, or material handling.

The compact design will allow you to use cylinders in mobile systems where the weight and size of the equipment are of primary importance. For example, they are in demand in robotics, medical equipment, and even laboratory installations. Due to their versatility, such cylinders can become an effective solution for you in both small and large projects.

Types of Festo Round Cylinders

It’s important for you to understand the types of devices when you choose cylinders for a specific application. Festo round pneumatic cylinders are available in different configurations, allowing you to choose the optimal solution for your production.

Single-Acting Round Cylinders

Single-acting round cylinders operate by supplying air in one direction only. You can use them in applications where simplicity of design and cost-effectiveness are required. These cylinders are often used for linear movements, such as lifting or moving light objects. With minimal air consumption, they help reduce operating costs. You will also appreciate their durability, which is ensured by high-quality materials and advanced Festo technology.

Double-Acting Round Cylinders for Precise Control

If your application requires more complex motion control, double-acting round cylinders are a great choice. You can use them to move loads in both directions, making them a versatile solution for most automation systems. These cylinders provide high precision, which is especially important in assembly or packaging applications.

Specifically, their design allows them to withstand significant loads without losing performance. In fact, you can use them in intensive applications without worrying about frequent maintenance.

Benefits of Festo Round Cylinders

Festo cylinders are the equipment that will provide you with a high number of advantages that will allow you to optimize production processes.

Space-Saving Design for Compact Installations

One of the main advantages of such cylinders is their compactness. You can use them in systems where space is limited. For example, these can be mobile installations or small production lines.

Reliable Performance in Industrial Environments

Indeed, Festo cylinders demonstrate high reliability even in the most difficult operating conditions. Their design provides protection against dust, moisture, and other negative factors, which makes them an excellent choice for industry.

Easy Integration with Automation Systems

Automation cylinders for tight spaces are easy to integrate into existing automation systems. You can set up their parameters in no time thanks to compatibility with other Festo products.

Durability and Corrosion Resistance

The cylinder materials are designed for a long service life. You can use them in high-humidity environments or in contact with aggressive substances without fear of corrosion.

Increased Energy Efficiency

Energy conservation plays an important role in modern production systems. Festo round cylinders help reduce energy consumption thanks to their intelligent design.

Wide Range of Applications

You can use the cylinders in a wide range of industries, including the food industry, pharmaceuticals, and mechanical engineering. Their versatility allows them to be used in both standard and specific applications.

Minimized Maintenance Costs

Festo round cylinders are designed for a long service life and minimal component wear. You can reduce maintenance and replacement costs thanks to their robust design and high-quality materials. This is especially important for companies where machine downtime is unacceptable.

Resistance to Extreme Temperatures

Festo cylinders operate over a wide temperature range, making them suitable for use in both cold and hot environments. For example, you can use them in refrigeration systems or in systems with high thermal loads without losing efficiency.

Why Choose Festo Round Cylinders from ELTRA TRADE

When you choose equipment, it is important to consider its characteristics and the reliability of the supplier. Eltra Trade offers you Festo products with a quality guarantee and full technical support.

High-Quality Cylinders for Precision Motion

Festo round pneumatic cylinders are ideal for applications that require high precision and stability. You can count on the durability of the equipment, ensuring the stability of your production processes.

Comprehensive Range of Products

Eltra Trade offers a wide range of cylinders that are suitable for any task. You will be able to find a solution for both standard and specialized applications. So, when you choose Festo round cylinders from Eltra Trade, you get high-quality equipment and confidence in its reliability and efficiency.