Festo Sensors

Festo PE

Festo SDE3

| Start value for pressure measuring range | 0 bar |

| End value for pressure measuring range | -1 bar |

| Switching element function | Switchable |

Festo SFAB

| Flow characteristic curve end value | 1000 l/min |

| Operating medium | Compressed air to ISO 8573-1:2010 [7:4:4] - Nitrogen |

| Operating pressure | 0 bar - 10 bar |

Festo SFAB

| Flow characteristic curve end value | 50 l/min |

| Operating medium | Compressed air to ISO 8573-1:2010 [6:4:4] - Nitrogen |

| Operating pressure | 0 bar - 10 bar |

Festo SMT-8M-A

Festo NEBU

| Electrical connection 1, connection type | Socket |

| Electrical connection 1, connector system | G7/8 coded to NFPA/T3.5.29 R1-2007 |

| Electrical connection 2, connection type | Cable |

| Electrical connection 2, connector system | Open end |

Festo NEBU

| Electrical connection 1, connection type | Socket |

| Electrical connection 1, connector system | M12x1, A-coded to EN 61076-2-101 |

| Electrical connection 2, connection type | Plugs |

| Electrical connection 2, connector system | M12x1, A-coded to EN 61076-2-101 |

Festo NEBU

| Electrical connection 1, connection type | Socket |

| Electrical connection 1, connector system | M12x1, A-coded to EN 61076-2-101 |

| Electrical connection 2, connection type | Cable |

| Electrical connection 2, connector system | Open end |

Festo NEBU

| Electrical connection 1, connection type | Socket |

| Electrical connection 1, connector system | M12x1, A-coded to EN 61076-2-101 |

| Electrical connection 2, connection type | Cable |

| Electrical connection 2, connector system | Open end |

Festo NEBU

| Electrical connection 1, connection type | Socket |

| Electrical connection 1, connector system | M12x1, A-coded to EN 61076-2-101 |

| Electrical connection 2, connection type | Cable |

| Electrical connection 2, connector system | Open end |

Festo PE

Festo PEN

| Operational voltage range DC | 12 V - 30 V |

| Operating pressure | -1 bar - 8 bar |

| Switching element function | N/O contact |

| Pneumatic connection | M5 |

Festo PEV

Festo PEV

Festo PEV

Festo PEV

Festo PEV

Festo PEV

Festo PEV

Festo PPL

Festo PPL

Festo RFL

Festo RFL

Festo RML

Festo SAMH

Festo SDAS-MHS

| Design | For T-slot |

Festo SDAT-MHS

| Design | For T-slot |

| Sensing range | 0 µm - 100000 µm |

| Analogue output | 4 - 20 mA |

Festo SDAT-MHS

| Design | For T-slot |

| Sensing range | 0 µm - 125000 µm |

| Analogue output | 4 - 20 mA |

Festo SDAT-MHS

| Design | For T-slot |

| Sensing range | 0 µm - 160000 µm |

| Analogue output | 4 - 20 mA |

If you want to achieve a high level of efficiency and stability in your production processes, then you cannot do without precise and reliable equipment. Your industrial system requires constant monitoring to avoid failures and costly downtime. Festo sensors are the solution – innovative devices that guarantee precise measurement and monitoring of key performance indicators of your equipment. Festo sensors are ideal for controlling your industrial processes, and monitoring parameters such as position, pressure, temperature, and liquid levels.

These high-tech devices help optimize the operation of your production systems, minimizing the risk of accidents and increasing the accuracy of work. Thanks to the integration with automated control systems, Festo sensors provide the ability to monitor and analyze the condition of equipment in real time. Moreover, they are ideal for industrial automation, ensuring control at every stage of the production cycle.

In this section, we will take a closer look at the range of Festo sensors and the benefits of using them. You will learn what types of sensors exist and why they are essential for the successful operation of your enterprise.

Explore Our Range of Festo Sensors

Festo offers a wide range of sensors for a wide range of applications. In their portfolio, you will find devices that help you monitor production parameters with high precision. Regardless of whether you work in industrial automation, logistics, or mechanical engineering, Festo Sensors will be your reliable partner.

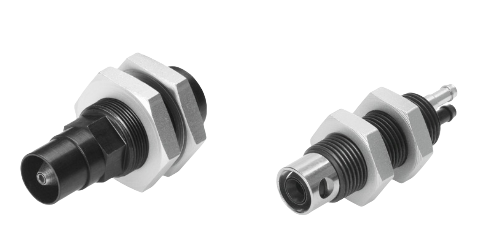

Festo proximity sensors are used to detect the position of objects. These proximity sensors are ideal for systems that require precise positioning of parts, such as assembly lines or transport systems. They trigger when an object approaches a specified distance, allowing you to automate inspection processes and minimize errors.

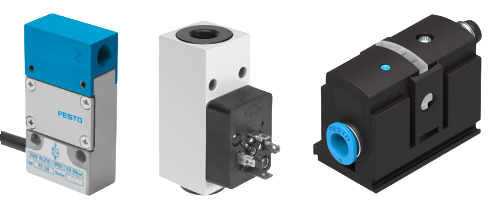

Your production process may also require pressure monitoring. Festo pneumatic pressure sensors provide precise pressure measurement in pneumatic systems. They help to maintain optimum machine performance, which is especially important under high loads and intensive use.

If your plant uses cylinders, consider Festo pneumatic cylinder sensors. These sensors monitor the position of the piston in the cylinder, ensuring precise operations. Importantly, these sensors are easy to integrate into automation systems and guarantee high precision and reliability. The Festo sensor range is designed to meet the most stringent quality and safety requirements. Each sensor undergoes rigorous testing to ensure its reliable and long-lasting operation. By choosing Festo sensors, you get products that will serve you for many years, minimizing the need for frequent maintenance and replacement of equipment.

Benefits of Using Festo Sensors

The company offers you a lot of advantages that will convince you that this product is worthy of your attention. Let's sort these advantages in more detail.

High measurement accuracy

One of the main advantages of Festo automation sensors is their high accuracy. Regardless of whether you use sensors to measure pressure, and temperature or determine position, you can always be sure of the reliability of the data. Accurate measurements help to avoid errors and failures in production processes, which is especially important for companies with high-quality requirements.

Reliability and durability

Festo sensors are designed to work in the most difficult conditions. The use of high-quality materials and technologies ensures their reliability and long service life. Festo sensors are resistant to vibrations, high temperatures, and aggressive environments, which makes them an ideal choice for your production. They minimize the risk of equipment downtime and ensure its smooth operation.

Easy integration into automation systems

One of the important advantages of Festo sensors is their ease of integration into existing automation systems. Whether you are working with existing systems or developing new ones, position detection sensors and other devices from Festo are easy to connect and configure. This reduces the time it takes to implement new solutions and helps you quickly adapt your equipment to changing production needs.

Energy efficiency

Festo sensors are designed to minimize energy consumption. This not only reduces operating costs but also makes your production more environmentally friendly. Using energy-efficient solutions allows you to save on energy and reduce the negative impact on the environment.

Increased production safety

Using Festo sensors directly contributes to increased safety in production. They ensure early detection of critical changes in parameters such as overheating, pressure changes, or deviations from the normal position. This allows you to react to potential threats promptly and prevent emergencies, reducing the risk of injury to employees and damage to equipment.

Reduced maintenance costs

Another important advantage of using Festo sensors is the reduction of equipment maintenance costs. Thanks to their high reliability and durability, these devices require minimal maintenance. Fewer failures and equipment downtimes help you save money that could otherwise be spent on repairs or replacement of components.

Types of Festo Sensors

Festo offers many different types of sensors, each of which solves specific problems in production. Let's look at the main types of Festo sensors and their capabilities.

Proximity sensors

Festo sensors proximity are used to detect the position of objects in production. They trigger when an object approaches a specified distance, allowing you to accurately control processes such as moving materials along a conveyor or positioning parts on an assembly line. These sensors are highly reliable and can be used in the most difficult conditions.

Photoelectric sensors

These sensors are based on light and are used to detect objects or determine their position. They can be used for both short and long distances, making them universal for many production applications. These sensors are indispensable in systems that require precise positioning of objects without contact.

Pressure sensors

Festo industrial pressure sensors provide accurate pressure measurement in pneumatic systems. They are critical to maintaining the stability and safety of production processes. These sensors are highly sensitive and durable, allowing you to use them for many years without the need for frequent replacement.

Temperature sensors

Special temperature sensors are used to monitor temperature in industrial processes. They measure the temperature of both air and liquids, making them versatile for use in a variety of systems. Accurate temperature measurement helps maintain optimal operating conditions for equipment, preventing it from overheating or undercooling.

Level sensors

These devices are used to monitor the level of liquids in tanks and feed systems. They allow you to accurately measure the amount of material and warn when it is necessary to refill or drain. These sensors play an important role in preventing overfills and interruptions in the supply of raw materials, which is especially important for enterprises with automated processes.

Why Choose Festo Sensors?

Selecting sensors for your production is an important step that can affect the efficiency and reliability of your equipment. Festo sensors are characterized by high quality, precision, and durability, making them the perfect choice for your plant. Festo offers a wide range of sensors for every need. Whether you need to monitor pressure, liquid level, or detect the position of objects, you will find the optimal solution for your production in Festo cylinder sensors and other products.

Festo sensors are easy to integrate into existing automation systems. You do not have to spend a lot of time and resources on setting them up and connecting them. This significantly speeds up the process of implementing new solutions and helps your production remain competitive. In addition, Festo sensors are economical and energy-efficient. They help you reduce operating costs due to minimal energy consumption and a long service life. This makes them a good choice both in terms of costs and in terms of the sustainability of your plant.

Finally, Festo is a trusted brand that has been a market leader in industrial solutions for many years. The company's products have undergone numerous tests and certifications, which guarantees their high quality and safety. So, by choosing Festo sensors, you get equipment that will ensure the stable and efficient operation of your enterprise.