Festo Vacuum technologies

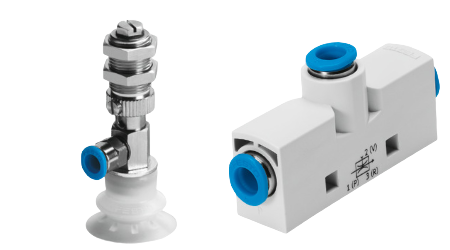

Festo VN

| Nominal size, Laval nozzle | 1.4 mm |

| Max. vacuum | 88 % |

Festo ESF

Festo ESG

Festo ESG

Festo ESG

Festo ESG

Festo ESG

Festo ESG

Festo ESG

Festo ESG

Festo ESG

Festo ESV

| Suction cup diameter | 20 mm |

| Suction cup shape | Round, flat |

Festo ISV

Festo ISV

Festo ISV

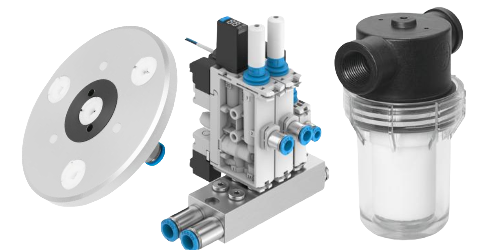

Festo OGGB

| Gripper diameter | 60 mm |

Festo OVTL

Festo VAD

Festo VAD

Festo VAD

Festo VAD

Festo VAD-M

| Nominal size, Laval nozzle | 1.4 mm |

| Max. vacuum | 85 % |

Festo VAD-M

| Nominal size, Laval nozzle | 0.95 mm |

| Max. vacuum | 85 % |

Festo VAD-M

| Nominal size, Laval nozzle | 2 mm |

| Max. vacuum | 85 % |

Festo VAD-M

| Nominal size, Laval nozzle | 1.4 mm |

| Max. vacuum | 90 % |

Festo VAD-M

| Nominal size, Laval nozzle | 0.95 mm |

| Max. vacuum | 90 % |

Festo VAD-M

| Nominal size, Laval nozzle | 2 mm |

| Max. vacuum | 90 % |

Festo VADMI

| Nominal size, Laval nozzle | 1.4 mm |

| Max. vacuum | 85 % |

Festo VADMI

| Nominal size, Laval nozzle | 1.4 mm |

| Max. vacuum | 85 % |

Festo VADMI

| Nominal size, Laval nozzle | 2 mm |

| Max. vacuum | 85 % |

Modern industrial processes require advanced solutions that can increase the efficiency and precision of production. Vacuum technologies developed by Festo are one of the main tools to help your business achieve these goals. The leading role of Festo vacuum technologies in the automation of industrial processes is explained by their ability to ensure fast and precise processing of various materials and their versatility in application.

Thanks to many years of experience and innovation, Festo has established itself as a world leader in developing and producing vacuum generation equipment. Using these technologies guarantees you not only high productivity but also optimized energy consumption, which is becoming increasingly important in the context of modern requirements for sustainable development.

What is the Vacuum Technology?

Vacuum technology is the process of creating a space with a pressure below atmospheric pressure, which allows the use of vacuum forces to grip, move, and fix objects. In industry, it is widely used to automate the processing and movement of materials, which significantly increases the accuracy and speed of operations. Thanks to the development of technologies such as vacuum technologies, the use of vacuum has become the standard for various industries that require high speed and accuracy.

Using vacuum solutions such as Festo vacuum systems helps optimize work in automated systems where error-free operations are required. The advantages of vacuum technologies are their ability to work with a wide range of materials and products while ensuring the stability and reliability of production processes.

Key Features and Technical Specifications

One of the main characteristics of vacuum technologies is their ability to quickly create a vacuum in work areas, which ensures high speed of material handling and movement tasks. Vacuum generators and pumps used in Festo systems provide the necessary pressure to create an effective vacuum, which will allow you to cope with even the most complex production tasks. For example, the Festo vacuum generator can instantly create the required vacuum, which allows you to reduce the cycle time of material processing.

The technical parameters of Festo vacuum equipment vary depending on the needs of your production. Some of them can work with a high level of vacuum, which makes them ideal for use in conditions that require precision processing and accuracy. Other systems can be adapted to work with heavier materials or for use in conditions of high humidity or contamination.

In addition, it is worth noting the possibility of integrating vacuum systems into existing automated lines. This will allow you to modernize production without having to completely replace equipment. Modern vacuum solutions from Festo can be easily integrated with robotic systems and other automation systems, which simplifies the processes of introducing and using vacuum technologies in production. Another important aspect is the flexibility in equipment settings. Festo vacuum systems can be configured to work with different types of materials and objects, which makes them universal and applicable in a wide range of industries. Using vacuum technologies will allow you to achieve significant improvements in productivity and production efficiency.

The Role of Vacuum Systems in Industrial Automation

In today's manufacturing environment, vacuum systems are essential for increasing productivity and precision. They automate processes that were previously only possible with manual labor. For example, vacuum technology makes it much easier for you to handle and process fragile and lightweight materials, which is important in industries such as electronics or pharmaceuticals.

Festo vacuum systems help reduce the error rate in material handling because they hold parts firmly and securely during operations. This is especially important in automated production lines where precision is critical. Vacuum systems can be integrated into quality control systems, ensuring continuous monitoring of the production process and reducing defects.

In addition, Festo vacuum technologies can be used for handling materials that require delicate handling, such as glass, plastic, or paper. Using a vacuum to fix such materials prevents damage and significantly improves the quality of the final product.

Another important aspect is the ability to use energy-efficient vacuum technology, which will allow you to significantly reduce energy costs in production processes. Such systems allow for the optimization of energy use, which is especially important for companies seeking to reduce operating costs.

Different Types of Festo Vacuum Technologies

The wide range of industrial vacuum technologies offered by Festo includes a variety of solutions that can meet the most diverse requirements for production processes. Depending on the specifics of your industry, you can choose the right system that will ensure maximum productivity and efficiency.

Vacuum Generators and Pumps Explained

Festo vacuum generators and pumps are the main elements that ensure the creation of a vacuum in automated systems. These devices are responsible for creating the rarefied space necessary for gripping and moving objects. Vacuum generators use the ejection principle, which allows them to quickly and efficiently create a vacuum without the need for complex mechanical components. In addition, the pumps used in vacuum systems are characterized by high performance and energy efficiency. This allows for a significant reduction in operating costs, which is especially important for companies operating in conditions of high energy costs.

Suction Cups and Grippers for Precision Handling

One of the key elements of Festo vacuum systems are suction cups and grippers used for precise processing and handling of materials. These components ensure reliable contact with the material being processed and allow operations to be performed with high precision. The use of a vacuum component, such as suction cups, allows working with a wide range of materials from glass to metal.

Festo suction cups are developed taking into account the specifics of the material being processed, which helps to minimize the risk of damage and ensure high productivity. The use of such solutions improves product quality and reduces the number of defects in production.

Key Benefits of Festo Vacuum Technologies

The use of Festo vacuum technology in automated systems offers several significant advantages that can significantly improve the efficiency of your production.

Optimized Material Handling Solutions

Using Festo vacuum systems will allow you to achieve high precision and speed of material processing. The systems are specially designed to work with a wide range of materials, ensuring their reliable fixation and transportation.

Superior Performance in Automated Operations

Festo vacuum systems provide high productivity in automated production environments. Fast response and reliable operation of the equipment reduce processing times and increase overall productivity.

Energy-Efficient Vacuum Generation Systems

Festo vacuum technology allows you to reduce energy costs by optimizing the operation of vacuum generators and pumps. Such systems provide high performance with minimal energy consumption.

Easy to Integrate

Festo vacuum technology can be easily integrated into existing production lines, allowing you to quickly and cost-effectively implement new solutions in your company.

Reliability and Durability

Festo equipment is highly reliable and durable, allowing you to reduce maintenance and operating costs and avoid production downtime.

Use in Aggressive Environments

Festo vacuum systems can be used in high humidity, dust, or high temperatures, making them ideal for use in difficult production environments.

Versatility

Vacuum systems can be configured to handle a wide range of materials, allowing you to use them in a variety of industries, from food to pharmaceuticals.

Primary Applications for Festo Vacuum Technologies

Festo vacuum technologies are widely used in various industries due to their versatility and high productivity. Festo vacuum technologies allow you to automate processes that require precision and speed.

Robotics Integration and Material Handling

One of the main areas of application of vacuum technologies is their integration into robotic systems. Material handling with vacuum systems allows robots to effectively grip and move materials, ensuring high precision and speed of operations.

Pharmaceuticals

Vacuum technologies are used for precise dosing and movement of drugs, which minimizes contact with the product and reduces the risk of contamination.

Food industry

Vacuum systems are used for packaging food products, ensuring the tightness and safety of products during transportation and storage.

Automotive industry

Vacuum technologies are used for the assembly and movement of various components of cars, ensuring high precision and reliability of assembly.

Electronics

Vacuum systems help process and move fragile components of electronic devices, which improves the quality of assembly and reduces the percentage of defects.

Logistics

Vacuum systems are used to automate processes in warehouses and logistics centers, ensuring efficient movement of goods.

Why Choose Festo Vacuum Technologies from ELTRA TRADE?

Eltra Trade is an official supplier of Festo solutions and offers you a wide range of devices for production automation. When purchasing equipment from us, you receive reliable equipment with a quality guarantee, as well as professional technical support at all stages of operation. We provide fast deliveries and competitive prices, which makes our cooperation accessible to enterprises of any level. By contacting us, you can be sure that you will receive the most advanced solutions for your business, developed taking into account the modern requirements of the vacuum technology industry.