IFM IO-Link

- 20...30 DC; (US; according to SELV/TBTP)

- 300...3900; (US)

- 16; (configurable)

- DataLine

- DC

- M12 Connector

ifm 4 pin cable color code

- Minimum bending radius: 5 x cable outer diameter

- Permissible movement speed: up to 10 m/s

- Permissible acceleration: up to 50 m/s²

I/O modules for field applications, 4 IO-Link ports / 4 digital inputs, Profibus DP interface, Sockets M12 x 1

I/O modules for field applications, 8 inputs, Profibus DP interface, Sockets M12 x 1

IO-Link master with Profinet interface, max. 8 IO-Link ports / max. 12 digital inputs / max. 8 digital outputs, I/O modules for field applications

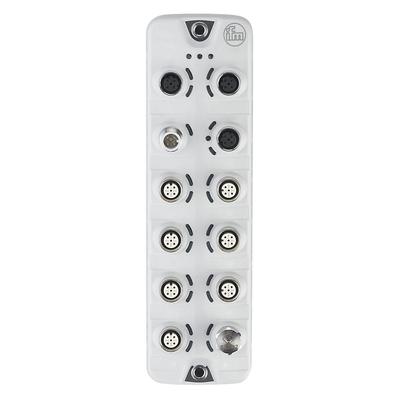

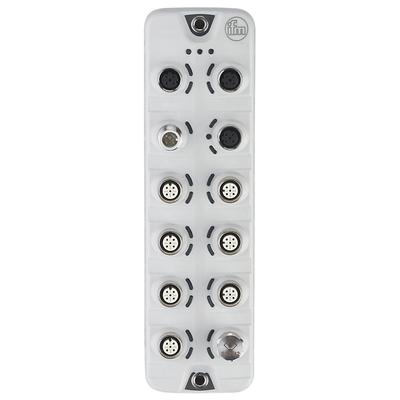

IO-Link master with Profibus interface, max. 8 IO-Link ports / max. 12 digital inputs / max. 8 digital outputs, I/O modules for field applications, Sockets M12 x 1

IO-Link master with EtherNet/IP interface, max. 8 IO-Link ports / max. 12 digital inputs / max. 8 digital outputs, I/O modules for field applications, Sockets M12 x 1

IO-Link master with EtherCat interface, max. 8 IO-Link ports / max. 12 digital inputs / max. 8 digital outputs, I/O modules for field applications, Sockets M12 x 1

IO-Link Master SL PN 4P IP67

IO-Link Master SL PN 8P IP67

IO-Link Master SL PN 8P IP69K

IO-Link Master SL EIP 8P IP69K

IO-Link Master PL PN 4P IP69K

IO-Link Master PL PN 8P IP67

IO-Link Master PL PN 8P IP69K

IO-Link Master PL EIP 4P IP69K

IO-Link Master PL EIP 8P IP67

- DataLine

- DC

- M12 Connector

- DataLine

- DC

- M12 Connector

- DataLine

- DC

- M12 Connector

- DataLine

- DC

- M12 Connector

- DataLine

- DC

- M12 Connector

- DataLine

- DC

- M12 Connector

- DataLine

- DC

- M12 Connector

- DataLine

- DC

- M12 Connector

- DataLine

- DC

- M12 Connector

- DataLine

- DC

- M12 Connector

- DataLine

- DC

- M12 Connector

- CabinetLine

- DC

- RJ45 Connector

The emergence and development of IO-Link technology is driven by the market demand for low-cost digital and analog transducers and detectors capable of exchanging diagnostic and configuration data with the controller using poor-expense numeric connection mechanism when sustenance inversely reconcilability with now spent numeric inlet/outlet calls. DI/DO output.

The controller can be a personal computer (PC) or a programmable consistency controller (PLC, PLC). Through the combined efforts of leading manufacturers of sensors and automation installation, the interface has been created, the specification of which takes into account the above requirements. As with other manufactured supplements, IO-Link mechanism is use from increased adoption of microcontrollers embedded in numerical/analog actuators and drives.

IO-Link engineering is presently being standardized as the IEC 61131-9 standard, which in turn is piece of a range of norms on programmable controllers and related peripherals.

What is IO-LINK?

IO-Link is intebded for area use, they are gateways for copulative up to 8 IO-Link units, like actuators, valves or discrete in/out modules. In some embodiments, some ports are designed as B ports and also provide auxiliary capacity for linking IO-Link drives. The wizard is used to pass apparatus facts, act options and rating information to the controller.

The product band comprises interfaces for Profinet, Ethernet/IP, Profibus. High resistance to electromagnetic interference, big temperature sequence, high advocacy and robust housing allow it to be used in tough manufactured environs. The Wizard with AS-Interface has a quick build technology in which the upper and lower parts are fixed using a sled.

The IO-Link Master for mounting in the control cabinet has a built-in web server for configuration and diagnostics. It conveys engineinformation, operation options and rating records to the controller throughout Profinet. The gear has an another Ethernet hole with a built-in switch, so that this data can also be processed in IT, in enterprises or even around the world. This second port provides a direct network connection between all coupled IO-Link units and the spot server via a parallel communication channel, the so-called Y-channel.

The built-in software of the LINERECORDER AGENT interface ensures the security of connection with the server.

IO-Link allows relations with detectors and drives and closes the last counter in the process with unchanged data transparency. Full association into the Complete Combined Automation (TIA) construct truly unlocks the full potential of this communication standard – both in the control cabinet and in the field.

Intelligent IO-Link control software

Efficient: Centralized parameterization of every IO-link actuators with simply one software tool. Manufacturer independent

Intelligent: Automatic discovery of IO-Link devices

Convenient: managing parameter datasets is easier than ever

Direct: straight admission to IO-Link detectors out of using a PLC

IFM IO Link Sensors

Masters / modules

- IO-link eccentric

- IO link mods

Transducers / Identification

- provision actuators

- act sensors

- sensors for move inspection

- authentication systems

Display / Estimate / Join

- arrangements

- materials/ connexion technology

Parameterization / actuator kits

- software

- starter kits