Keyence

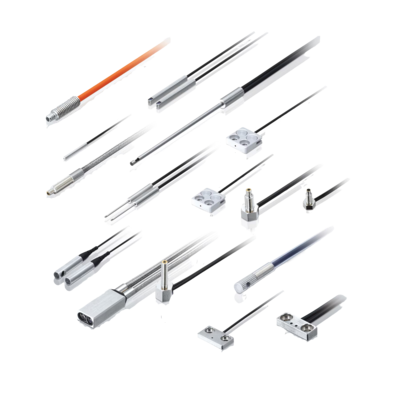

em 030

- Sensor type: inductive

- Sensor diameter: 3 mm

- Detection range: 2.5 mm

- Polarity: NPN, PNP

- Operating temperature: -10...+70 °C

Keyence FSM1P cable optical amplifier

- Type: Cable optical amplifier

- Output type: PNP open collector

- Maximum current: 50 mA

- Maximum voltage: 40 V DC

keyence fs v21rp

- Amplifier type: cable

- Output type: PNP

- Maximum output current: 100 mA (40 V DC)

- Two-digit display: measuring range from 0 to 999.9

keyence fs2 60

- Amplifier type: cable

- Maximum output voltage: 20 В

- Maximum output current: 100 mA

- Polarity: NPN, PNP

keyence pz2 61

- Technology: reflected light detection

- Built-in amplification: yes

- Operating temperature range: -10 to 50 °C

- Operating voltage: 12 to 24 VDC

IN STOCK!!!

- NPN+PNP

- Threaded mount type

- Diffuse reflective (Long distance)

- Detecting distance - 500 mm

Keyence Corporation was founded in 1974 in Osaka, Japan, with a vision to revolutionize industrial automation through advanced technology and innovation. From its beginnings as a small manufacturer of sensors and automation components, Keyence has grown into a global leader in the field, known for its pioneering approach and commitment to excellence.

Keyence’s role in industrial automation is multifaceted and crucial to the advancement of manufacturing and process control. The company’s products are designed to enhance efficiency, precision, and reliability across various industries. Keyence’s extensive product lineup includes:

- Sensors: A wide variety of sensors are available from Keyence, such as photoelectric, fiber optic, laser, inductive proximity, and more. Because of their reputation for precision and sturdiness, these sensors are crucial for a wide range of industrial applications.

- Vision Systems: High-resolution images and advanced processing capabilities are offered by Keyence's vision systems. These systems are essential to quality control and inspection procedures because they let companies find flaws in products, confirm their integrity, and precisely operate automated machinery.

- Measurement Instruments: The company’s measurement instruments deliver accurate and reliable data for a wide range of applications, including dimensional measurement, surface analysis, and more. These instruments are vital for ensuring product quality and process accuracy.

- Programmable Logic Controllers (PLCs): Keyence PLCs offer advanced control and automation capabilities, allowing businesses to integrate and manage various automation components effectively. These controllers are known for their flexibility, performance, and ease of use.

With a presence in over 40 countries, Keyence combines global reach with localized expertise. The company’s commitment to customer support is evident in its comprehensive service offerings, including product selection assistance, technical support, and on-site troubleshooting. Keyence’s ability to provide tailored solutions and responsive support helps businesses maximize the value of their automation investments.

Keyence’s products are designed to optimize industrial processes, enhancing operational efficiency and productivity. By integrating Keyence technologies, businesses can achieve smoother operations, reduce downtime, and improve product quality. Additionally, Keyence is dedicated to sustainability, developing solutions that minimize environmental impact and support greener industrial practices.

Keyence Sensors

Keyence has built a solid reputation for creating inventive, high-performance sensors that can be used in a variety of industrial settings. Their sensor lineup is distinguished by cutting-edge technology, sturdy construction, and intuitive design.

- Photoelectric Sensors: Wide range of Keyence photoelectric sensors that use LED light sources to identify if an object is there or not. These sensors perform exceptionally well in a variety of applications, such as color, position, and object identification.

- Fiber Optic Sensors: Designed for challenging environments, Keyence fiber optic sensors provide exceptional flexibility and durability. They are ideal for applications involving small objects, high-speed detection, and harsh conditions.

- Laser Sensors: Keyence laser sensors use a concentrated laser beam to provide accurate long-range detection. These sensors are ideal for high-accuracy applications like level detection, object placement, and distance measuring.

- Inductive Proximity Sensors: Without making physical contact, metal items can be detected by Keyence inductive proximity sensors. These sensors have a reputation for being dependable, quick, and resistant to contamination.

- Positioning Sensors: Keyence positioning sensors for precise object location and alignment. These sensors find applications in assembly, packaging, and material handling processes.

- Vision Sensors: Keyence vision sensors offer extensive object inspection and measuring capabilities by utilizing cutting-edge image technology. These sensors are employed in process optimization, defect detection, and quality control.

Benefits of Using Keyence Sensors

Keyence sensors offer a multitude of advantages that can significantly enhance production efficiency, quality, and overall operational performance.

Improved Productivity

- Increased throughput: The high-speed response times of Keyence sensors are well known, allowing for quicker cycle times and higher production output.

- Reduced downtime: Keyence sensors reduce equipment failures and unscheduled downtime since they are designed to resist tough industrial conditions.

- Simplified setup: The intuitive design and user-friendly interfaces of Keyence sensors reduce setup time and training requirements, allowing for quicker system integration.

Enhanced Quality

- Improved accuracy: Keyence deliver exceptional precision, enabling tighter tolerances and reduced defects.

- Enhanced reliability: Keyence sensors' sturdy design and cutting-edge technology guarantee dependable and constant performance, which raises the caliber of the final output.

- Advanced inspection capabilities: Keyence vision sensors offer comprehensive inspection capabilities, such as defect detection, measurement, and code reading, to maintain stringent quality standards.

Cost Reduction

- Lower maintenance costs: Keyence sensors are designed for long-term reliability, reducing maintenance and repair expenses.

- Reduced scrap rates: Improved accuracy and defect detection capabilities lead to lower scrap rates, saving material and labor costs.

- Optimized energy efficiency: Keyence sensors often incorporate energy-saving features, contributing to reduced operating costs.

Operational Efficiency

- Flexible deployment: In order to accommodate a broad range of applications, Keyence offers a variety of sensors that are flexible and adaptable to shifting production needs.

- Data-driven insights: Keyence sensors can generate valuable data that can be used for process optimization and predictive maintenance.

- Ergonomic design: Many Keyence sensors feature ergonomic designs, improving operator comfort and reducing fatigue.

Keyence Sensors in Across Industries

Keyence sensors have become indispensable tools in a wide array of industrial sectors, contributing significantly to process optimization, quality enhancement, and overall productivity.

- Automotive: Keyence sensors are ubiquitous in automotive manufacturing. They are employed in assembly, welding, painting, quality control, and logistics. Keyence sensors are reliable and precise in measuring intricate geometries and detecting minute components.

- Electronics: The electronics industry relies heavily on Keyence sensors for component placement, inspection, and assembly. Their ability to handle high-speed operations and minute details is crucial for this sector.

- Packaging: Keyence sensors are used to enhance packaging operations in a variety of industries, such as consumer products, medicines, and food and beverage. They guarantee proper quality control, labeling, and handling of the product.

- Metalworking: In metalworking, Keyence sensors contribute to precision machining, welding, and cutting operations. They monitor machine performance, detect part presence, and ensure dimensional accuracy.

- Logistics and Material Handling: Keyence sensors automate inventory management, tracking, and sorting processes, which simplifies logistical operations. They improve distribution centers' and warehouses' accuracy and efficiency.

- Food and Beverage: Keyence sensors are used for product inspection, quality control, and packaging in the food and beverage industries. They guarantee product safety and aid in upholding hygienic standards.

Emerging Applications

Beyond these core industries, Keyence sensors are increasingly adopted in:

- Pharmaceutical: Keyence sensors support the stringent quality and safety requirements of the pharmaceutical industry. They are used in production, packaging, and quality control.

- Textile: The textile industry leverages Keyence sensors for fabric inspection, color matching, and quality control. They contribute to consistent product quality and reduced defects.

- Paper and Printing: Keyence sensors optimize paper and printing processes by ensuring accurate paper feeding, print quality control, and sheet counting.

- Plastics: In the plastics industry, Keyence sensors are used for part inspection, measurement, and assembly. They contribute to product consistency and reduced waste.

- Renewable Energy: Keyence sensors are finding applications in renewable energy sectors, such as solar panel manufacturing and wind turbine maintenance.