Omron Other Sensors

omron capacitive proximity sensor

- Case size: M8, M12, M18, Ø22

- Body shape: Cylindrical, rectangular

- Mounting type: Threaded, flush, on a bracket

- Material of detecting surface: ABS plastic, stainless steel, PTFE

- Sensitivity: Adjustable or fixed

- Trigger time: 0.2ms (typical)

- Indication: LED indicator

art. E2K 5003B

Omron capacitive sensor E2K-C series

Omron e2k c25my1

Capacitive Sensor Omron E2K Series

Omron Capacitive proximity sensor - E2K Series

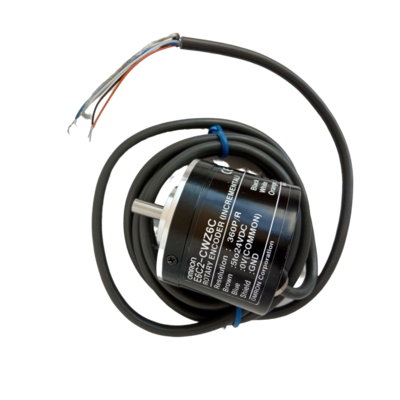

e6c2 cwz6c omron

- Type: Quick disconnect

- Size: 1/4" NPT

- Pressure: 16 bar

- Temperature: -20...+80°C

- Material: Nickel chrome steel

art. E8F20002M

Pressure Transmitter Omron E8F2 series

art. E8PC0007R

Omron Pressure Sensor - E8PC series

art. E8PC0001M

Omron Pressure Transducer E8PC series

omron fiber amplifier

- Current consumption: 10-50 mA

- Degree of protection: IP65, IP67

Omron Reflective Sensor

- Degree of protection: IP65 or IP67

- Body material: ABS plastic or metal

Omron retro reflective sensor

Detection spot size:

- Standard models: from 1 mm to 50 mm

- Miniature models: from 0.5 mm to 2 mm

- Models with a large detection range: up to 10 m

Omron Temperature Sensor

- Supply voltage: 3 V to 24 V

- Current consumption: 1 mA to 10 mA

- Protection: IP67, IP68

- Mounting: threaded, DIN rail, terminal block

- Body material: stainless steel, brass, plastic

V430 Code Reader art. V4305326M

omron e39 f4

- Carbide blades provide clean and even cuts.

- Ergonomic handle with rubberized coating provides a comfortable grip.

- Safety lock prevents accidental opening of the blades.

- Suitable for cutting fiber optic cables up to 4 mm in diameter.

art. E2K 5005R

E2K-C series

art. E2K 5006G

E2K-C series

art. E2KF1020H

E2K-F series

art. E2KF1015A

E2K-L series

art. E2KF1014C

E2K-L series

art. E2KX1021M

E2K-X series

art. E2KX1073C

E2K-X series

art. E2KX1006G

E2K-X series

art. E2KX1061M

E2K-X series

art. E2KX1011C

E2K-X series

art. E2KX1016D

E2K-X series

art. E2KX1067R

E2K-X series

In the realm of industrial automation, the Omron Corporation is a towering example of creativity and dependability. Founded in Kyoto, Japan, in 1933, Omron has evolved into a global powerhouse, operating in over 120 countries and regions. Its commitment to excellence and customer satisfaction has solidified its reputation as a trusted leader in the industry.

Omron's sensors serve as the bedrock of its automation solutions, holding a crucial position in monitoring and regulating numerous parameters within industrial environments. The manufacturing process of Omron sensors are evidence of the company's constant commitment to quality and accuracy.

At Omron's cutting-edge manufacturing facilities, sensors are crafted using state-of-the-art technology and strict quality assurance procedures. From initial design to final assembly, each stage is carefully carried out to guarantee longevity and excellent performance.

Omron provides a broad selection of sensors, each designed to satisfy particular industrial needs, such as vision, environmental, photoelectric, and proximity sensors. Even in the most demanding settings, these sensors are designed to produce findings that are accurate and dependable.

Types of Omron Sensors and their applications

Omron Sensors offers a wide range of sensors for a variety of industries.

1. Proximity sensors

- How they work: Omron prox sensor identify objects even when they are not in direct contact with them. They employ a variety of technologies, including magneto-resistive, capacitive, inductive, and ultrasonic.

- Application: Extensively utilized in robotics, CNC machine tools, conveyor systems, and packing equipment.

2. Photoelectric sensors

- How they work: These photo sensor detect changes in the intensity of light reflected from an object. There are various varieties of them, including barrier, reflex, and diffuse.

- Application: They are used for counting objects, detecting defects, sizing, and sorting.

3. Fiber sensors

- How they work: These sensors use an optical fiber to transmit light to and from the sensor, allowing them to detect objects in hard-to-reach areas.

- Applications: Used in medical equipment, semiconductor industry, and laser machines.

4. Displacement sensors

- How they work: These sensors measure the distance or displacement between an object and a sensor. They come in different types such as laser, LED, ultrasonic, and contact.

- Applications: Used for part positioning, quality control, and thickness measurement.

5. Visual inspection sensors

- How they work: These sensors use cameras and software to analyze images and detect defects, objects, or patterns.

- Applications: Used for product inspection, character recognition, and robotics.

6. Code readers

- How they work: These sensors read information from 1D and 2D barcodes.

- Application: They are used in inventory tracking, access control, and manufacturing automation systems.

Integration and compatibility of Omron sensors

Omron sensors can be easily integrated with a variety of control and automation systems through a wide range of interfaces and communication protocols. Here are some of the most common ways to integrate Omron sensors:

1. Direct connection

- Many Omron sensors have built-in outputs that can be connected directly to the input or output ports of a controller or PLC.

- This is the easiest way to integrate Omron sensors, but it may not be as flexible as other methods.

2. Interface modules

- Omron offers a wide range of interface modules that can be used to connect sensors to various control systems.

- These modules typically convert sensor signals into a format that the control system can understand.

- Interface modules can provide additional functions such as signal amplification, filtering, and calibration.

3. Communication protocols

- Some Omron sensors support standard communication protocols such as RS-232, RS-485, and Ethernet.

- This allows the sensors to be connected to control systems via network connections.

- Communication protocols can provide flexibility and scalability, but they can be more difficult to configure than direct connection or interface modules.

Omron sensor compatibility

Omron sensors are compatible with a wide range of control and automation systems from different manufacturers.

Here are some factors to consider when determining the compatibility of Omron sensors:

- Sensor type: Different types of sensors have different outputs and interfaces.

- Control system: Make sure the control system supports the interface and communication protocol of the sensor.

- Power supply voltage: Ensure that the power supply of the control system is compatible with the supply voltage of the detector.

- Impedance of input and output: Ensure that the input and output impedance of the sensor is compatible with the impedance of the control system.

The importance of choosing the right sensors, such as Omron Sensors, cannot be overstated in industrial automation. Accurate sensing is crucial for optimal performance and efficiency. At Eltra Trade, our knowledgeable managers are always available to assist in selecting the best sensor solution for your specific needs, ensuring seamless integration and reliable operation in every application.