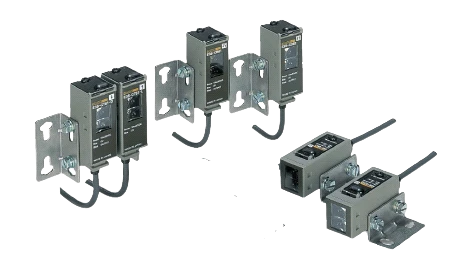

Omron E3S

omron e3s c

- Output type: NPN or PNP

- Maximum switching current: 100 mA

- Switching voltage: 25 V DC

art. e3s ad11

E3S series

art. E3S 3009R

e3s ad12

art. E3S 3172R

e3s ad13

art. E3S 3033A

e3s ad31

art. E3S 3035H

e3s ad32

art. E3S 3041B

e3s ad36

art. E3S 3042M

e3s ad37

E3S series

art. E3S 3059E

e3s ad61

E3S series

art. E3S 3061G

e3s ad62

E3S series

art. E3S 3153B

e3s ad63

E3S series

art. E3S 3067F

e3s ad66

E3S series

art. E3S 3164H

e3s ad66

E3S series

art. E3S 3085D

e3s ad81

E3S series

art. E3S 3087M

e3s ad82

E3S series

art. E3S 3167B

e3s ad83

E3S series

art. E3S 3093E

e3s ad86

E3S series

art. E3S 3094C

e3s ad87

E3S series

art. E3S 3162A

e3s ad88

E3S series

art. E3S 3005F

e3s ar11

E3S series

art. E3S 3014E

e3s ar16

E3S series

art. E3S 3021H

e3s ar21

E3S series

art. E3S 3031E

e3s ar31

E3S series

art. E3S 3040D

e3s ar36

E3S series

art. E3S 3057R

e3s ar61

E3S series

art. E3S 3066H

e3s ar66

E3S series

art. E3S 3083H

e3s ar81

E3S series

art. E3S 3092G

e3s ar86

E3S series

art. E3S 3001C

e3s at11

E3S series

art. E3S 3011M

e3s at16

E3S series

The Omron E3S series is a broad range of photoelectric sensors that use light-based technology to determine whether things are present or absent. These sensors can be employed in a wide range of industrial applications due to their well-known adaptability and versatility. Its ability to identify items without physical contact through the use of an infrared laser beam makes it suited for a variety of settings and environments.

Where Are Omron E3S Photoelectric Sensors Used ?

Omron E3S photoelectric sensors are extensively utilized in a wide range of applications and sectors because of its adaptability to diverse environments, dependability, and versatility. These sensors are perfect for a variety of industrial and automation activities since they can identify the presence or absence of items without coming into touch with them.

1. Manufacturing and Assembly Lines

They are used to detect the presence of components on assembly lines, triggering specific actions such as moving, sorting, or assembling parts. By providing precise detection, these sensors help maintain a smooth workflow and reduce errors in production processes.

2. Conveyor Systems

Detect when an item reaches a certain point, which can trigger additional processes like sorting, packaging, or quality checks. Their high-speed response and accuracy make them ideal for these dynamic environments, where quick and reliable detection is essential.

3. Packaging and Labeling

They detect the presence of products, ensuring that packaging machinery operates at the right time. These sensors help maintain quality control by confirming that items are correctly positioned and that labels are applied accurately.

4. Material Handling

They detect the position of materials, allowing robotic arms or other automated equipment to move and manipulate objects accurately. This use is particularly valuable in warehouses, distribution centers, and other logistics environments.

5. Safety Systems

These sensors can be used to trigger safety mechanisms, like shutting down machinery when an object or person is in an unsafe area. This program aids in maintaining worker safety and adherence to safety guidelines.

6. Quality Control

They are used to detect defects, measure dimensions, or verify that products meet specific criteria. By providing accurate detection, these sensors help companies maintain high standards of quality.

7. Automotive Industry

They help ensure that parts are correctly aligned and assembled, contributing to the efficiency and safety of the automotive manufacturing process.

Advantages of Using Omron E3S Photoelectric Sensors

Omron E3S photoelectric sensors offer numerous advantages that make them a popular choice in industrial and automation applications. These benefits are a result of Omron's extensive experience in the field, as well as the advanced technology and engineering behind the E3S series.

1. High Accuracy and Reliability

E3S sensors are designed to deliver precise and consistent detection. This accuracy ensures that the sensors perform reliably in a variety of industrial settings, reducing the risk of false triggers or missed detections.

2. Versatile Detection Modes

This versatility allows you to choose the most suitable sensor type for your specific application, whether it's long-range detection or close-proximity sensing.

3. Robust and Durable Design

With a high degree of protection (often IP67 or higher), they are resistant to dust, moisture, and temperature fluctuations. This durability ensures long-lasting performance, reducing the need for frequent replacements or maintenance.

4. Easy Installation and Integration

The sensors are compact and lightweight, with multiple mounting options to suit various setups. This flexibility makes it simple to integrate them into existing systems or new installations without extensive modifications.

5. Fast Response Time

This characteristic is crucial for industries where rapid detection and response are necessary, such as conveyor systems or automated assembly lines.

6. Energy Efficiency

Omron photo sensor are designed to be energy-efficient, with low power consumption. This feature not only helps reduce operational costs but also contributes to the environmental sustainability of your industrial processes.

7. Wide Supply Voltage Range

This feature allows you to use the sensors with various power configurations, enhancing compatibility with existing equipment.

8. Comprehensive Product Line

Omron offers a wide range of E3S photoelectric sensors, providing options for various detection needs and industrial applications. This comprehensive product line means you can find the right sensor for your specific requirements without compromising on quality or functionality.

Types of Omron E3S photoelectric sensors

Applications for omron photoelectric sensors include packaging lines, conveyor systems, factory automation, and access control.

- Reflected beam sensors: These sensors use light reflection from objects to detect them. They are frequently employed to find irregular or tiny things. Popular models: E3S-B, E3S-D, E3S-F.

- Direct-beam sensors: By breaking the light beam, these sensors are able to detect objects. They are often used to detect large or flat objects. Popular models: E3S-N, omron e3s c, E3S-G.

- Diffuse reflection sensors: These sensors detect objects by detecting scattered light. They are often used in difficult or dirty environments. Popular models: E3S-K, E3S-H, E3S-R.

- Retroreflective sensors: By reflecting light back to the sensor, these omron retro reflective sensor pick up objects. They are often used to detect objects at a great distance. Popular models: E3S-L, E3S-E, E3S-S.

Factors to consider when choosing a detector

- The type of object you want to detect: Different types of sensors are better suited for different objects.

- Reflected Rays: These sensors detect objects by bouncing light off of them. They are frequently employed to find irregular or tiny things.

- Direct beams: These sensors use beam interruption to identify objects. They are frequently employed to find big or flat things.

- Diffuse Reflective: These sensors detect objects by detecting scattered light. They are often used in complex or dirty environments.

- Retroreflective: By reflecting light back to the sensor, these sensors pick up objects. They are often used to detect objects at a great distance.

- The distance at which you want to detect an object is: Some sensors have a longer range than others.

- The environment in which the detector will be used: Some sensors are better suited for difficult or contaminated environments.

- Size and shape of the sensor: Some sensors are more compact than others.

- Price of the sensor: Omron photoelectric sensor price can vary depending on their features.

Popular models of Omron E3S photoelectric sensors:

- E3S-B, E3S-D, E3S-F: Reflected beam sensors

- E3S-N, E3S-C, E3S-G: Direct beam sensors

- E3S-K, E3S-H, E3S-R: Diffuse reflective sensors

- E3S-L, E3S-E, E3S-S: Retroreflective sensors

Steps to select an Omron E3S photoelectric sensor

- Determine the type of object you want to detect.

- Determine the distance at which you want to detect the object.

- Evaluate the environment in which the sensor will be used.

- Select the size and shape of the sensor that meets your needs.

- Determine your budget.

- Read the specifications and compare different sensor models.

- Choose the sensor that best meets your needs.

The correct sensor ensures precise detection, reduces downtime, and improves overall productivity.

If you're unsure about which sensor is best for your application or have questions about specific parameters, our Eltra Trade managers are here to help.