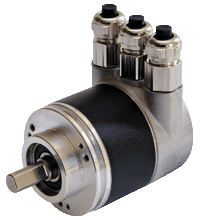

Pepperl+Fuchs Absolute Rotary Encoder

Pepperl+Fuchs Multiturn absolute encoder

- High resolution

- Precision

- Durable housing

- Wide range of applications

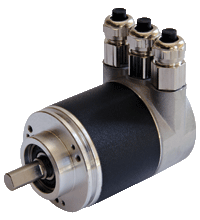

Pepperl Fuchs avm58n-011abr0gn-1212 Multiturn absolute encoder

- High positioning accuracy

- Data transfer rate up to 2 Mbps

- Reliable in operation

- Easy installation and configuration

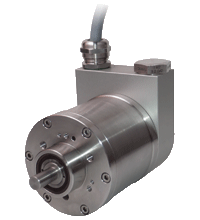

ENA58IL S10CA5 1213B17 ABP

- Body: AISI 303 stainless steel

- Shaft: AISI 303 stainless steel

- Bearings: Ball bearings

- Sealing: EPDM

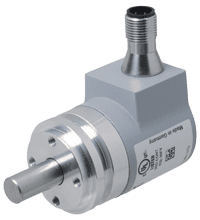

Multiturn absolute encoder PSM58

Industrial standard housing Ø58 mm

PROFIBUS interface

30 Bit multiturn

PVM58I 032AGR0BN 1213

- Shaft: Ø 6 mm, stainless steel

- Maximum torque: 1 Nm

- Maximum rotation speed: 1000 rpm

- Permissible radial runout: 0.1 mm

- Permissible axial runout: 0.2 mm

- Moment of inertia: 2.8 gcm²

- Industrial standard housing empty-58 mm

- 30 Bit multiturn

- Data transfer up to 2 MBaud

- Optically isolated RS 422 interface

- Zero-set function

- Hollow shaft

- Industrial standard housing empty-58 mm

- 30 Bit multiturn

- Hardware encoder

- Data transfer up to 2 MBaud

- Optically isolated RS 422 interface

- Hollow shaft

- Industrial standard housing empty-58 mm

- 16 Bit singleturn

- Data transfer up to 2 MBaud

- Optically isolated RS 422 interface

- Zero-set function

- Hollow shaft

- Industrial standard housing empty-58 mm

- 16 Bit singleturn

- Hardware encoder

- Data transfer up to 2 MBaud

- Optically isolated RS 422 interface

- Hollow shaft

- Industrial standard housing empty-58 mm

- 30 Bit multiturn

- Data transfer up to 2 MBaud

- Optically isolated RS 422 interface

- Recessed hollow shaft

- Zero-set function

- Industrial standard housing empty-58 mm

- 30 Bit multiturn

- Data transfer up to 2 MBaud

- Optically isolated RS 422 interface

- Servo or clamping flange

- Zero-set function

- Up to 4096 pulses on incremental track

- Industrial standard housing empty-58 mm

- 30 Bit multiturn

- Hardware encoder

- Data transfer up to 2 MBaud

- Optically isolated RS 422 interface

- Servo or clamping flange

- Up to 4096 pulses on incremental track

Industry standard enclosure Ø58 mm

16-bit single turn

- Data transfer up to 2 MBaud

- Up to 16 Bit singleturn

- ATEX-approval for mining

- IECEx approval

- Flameproof enclosure

- Removable connection cap

- Galvanically isolated RS 422 interface

- Industrial standard housing empty-58 mm

- 16 Bit multiturn

- Output code: gray and binary

- Transfer of position data with 4 AS-Interface slaves

- Parameterization and addressing via AS-Interface

- Servo or clamping flange

- High resistance to salt water

- Suitable for usage in corrosive enviroments of C4 category

- Two color status LED for easy installation

- 25-bit multiturn

- Y: Device specific encoder parameter settings

- Industrial standard housing empty-58 mm

- Servo or clamping flange

- 30 Bit multiturn

- Galvanically isolated CAN interface

- 2 limit switches

- 8 programmable cams

- Velocity and acceleration output

- Event triggered process data transfer

- Industrial standard housing empty-58 mm

- Servo or clamping flange

- 16 Bit singleturn

- Galvanically isolated CAN interface

- 2 limit switches

- 8 programmable cams

- Velocity and acceleration output

- Event triggered process data transfer

- Industrial standard housing empty-58 mm

- 25-bit multiturn

- Galvanically isolated DeviceNet interface

- Clamping flange

- Auto-saving function

- Up to 30 Bit multiturn

- ATEX approval

- IECEx approval

- Flameproof enclosure

- Removable connection cap

- Very small housing

- Up to 31 bit overall resolution

- CANopen interface

- Free of wear magnetic sampling

- High resolution and accuracy

- High climatic resistance

Pepperl+Fuchs Absolute Rotary Encoder: Ensuring Precision and Reliability

Pepperl+Fuchs manufactures a wide range of absolute rotary encoders, which are devices used to measure the absolute angular position of a rotating shaft or object. An absolute encoder is an angular position sensor providing information as a multi-bit digital code. Within the range of measured angular positions, each code is unique. After power-up, absolute encoders provide valid position information immediately without needing to move to the home position and search for zero marks.

Encoders currently produced by Pepperl+Fuchs can operate using different physical principles. The main ones are optical, in which changes in light beams are used to obtain information about the position; magnetic, in which work is carried out with changes in the magnetic field; and capacitive - in this case, changes in the electric field are used to determine position.

Below, we will closely examine the Pepperl Fuchs absolute rotary encoder, its features, applications, and specifications.

Highlighted Features of Pepperl+Fuchs Absolute Rotary Encoders

Here are some key features and details about Pepperl+Fuchs Absolute Rotary Encoder.

- Absolute position. These encoders provide an absolute digital output that represents the exact angle or position of the encoder shaft. This makes them ideal for applications where knowing the precise position is critical.

- Multi-turn and single-turn. Pepperl+Fuchs offers both multi-turn and single-turn absolute rotary encoders. Multi-turn encoders can measure the position over multiple rotations of the shaft, while single-turn encoders provide position information within a single rotation.

- Variety of communication interfaces. Pepperl+Fuchs Absolute Rotary Encoders typically come with various communication interfaces, including Profibus, Profinet, EtherNet/IP, and others, making them compatible with a wide range of industrial control systems.

- Solid and rugged design. These encoders are designed to withstand the harsh conditions often found in industrial environments. They are typically built to be robust, resistant to dust, moisture, and vibration, and capable of operating in a wide temperature range.

- High resolution. Absolute rotary encoders from Pepperl+Fuchs offer high-resolution output, allowing for precise measurement and control in industrial applications.

- Safety and redundancy features. Some models include safety features and redundancy options to ensure the reliability and safety of critical systems.

- Easy installation. Pepperl+Fuchs rotary encoders are designed for easy installation and integration into existing machinery and control systems.

Application Spectrum of Absolute Rotary Encoders

Pepperl+Fuchs Absolute Rotary Encoders are precision devices that provide accurate angular position information. Here are some common applications of Pepperl+Fuchs rotary encoder absolute.

- Industrial automation and robotics. Absolute rotary encoders are used in robotic arms and industrial automation systems to control the position and orientation of robotic arms precisely. This is critical for welding, assembly, and material handling tasks.

- CNC processing. Computer numerical control (CNC) machines use absolute rotary encoders to determine the exact position of the cutting tool, allowing for highly precise machining operations.

- Conveyor systems. Absolute rotary encoders help track the position and speed of conveyor belts and other material handling systems in manufacturing and logistics.

- Printing and packaging equipment. These encoders are used in printing presses, packaging machines, and labeling equipment to ensure precise printing and packaging processes.

- Renewable energy. Absolute rotary encoders are used in wind turbines and solar energy tracking systems to control the orientation of blades or solar panels. This helps optimize energy production by adjusting the position for maximum efficiency.

- Aerospace and defense industry. In aviation and military applications, rotary encoders are used to control the position of control surfaces, radar antennas, and other moving parts.

- Medical devices. Medical equipment such as MRI machines use absolute rotary encoders to control and precisely monitor the scanner's position and other moving parts.

- Heavy machinery and construction equipment. Absolute rotary encoders are used in bulldozers, excavators, cranes, and other heavy equipment to provide accurate information about the position of various components and ensure safe and efficient operation.

- Marine and offshore equipment. In marine applications such as ship propulsion systems and offshore drilling equipment, rotary encoders help monitor and control the position of critical components.

- Aviation. Absolute rotary encoders play an essential role in aircraft systems, including engine control and flight control systems, to ensure safety and accuracy during flight.

- Automotive manufacturing. These encoders are used on automobile assembly lines to position car body panels, monitor welding robots, and ensure precise component placement.

- Rail. On trains and trams, absolute rotation sensors help monitor the position of wheels and other components, ensuring safe and efficient operation.

- Food and beverage manufacturing. Absolute rotary encoders are used on food and beverage production lines to control equipment positions, such as filling and labeling machines.

- Textile industry. Textile machinery uses rotary encoders to precisely position components such as spindles and winding equipment in weaving and spinning processes.

- Testing of materials. In research and quality control, absolute rotary encoders are used to measure the rotation and position of test equipment and materials to ensure compliance with standards and specifications.

Technical Specifications Overview of Pepperl+Fuchs Encoders

Pepperl+Fuchs offers a wide range of rotary absolute encoder products. In single-turn absolute rotary encoders, after a full revolution has been completed, encoding begins from the initial value. And multi-turn absolute encoders record the number of courses. The range includes many options - cost-effective sensors for standard applications, heavy-duty versions, and rotary encoders for hazardous areas. And the most popular interfaces (EtherNet/IP, PROFINET IO, PROFIBUS, CANopen, IO-Link, Parallel interface, AS-Interface, SSI interface, DeviceNet) allow each of the Pepperl+Fuchs encoder range to be integrated without difficulty.

Pepperl+Fuchs offers a range of precision positioning solutions for hazardous areas and mines. ATEX and IECEx approvals allow this equipment to be used worldwide up to zone 1/21. In addition to compact versions for limited installation space, particularly robust versions are available for extreme environmental conditions.

Pepperl+Fuchs positioning products are ideal for extreme operating conditions that involve constant shock and vibration, high-bearing loads, dirt, and temperature fluctuations. These devices are characterized by maximum reliability even in the most adverse conditions.