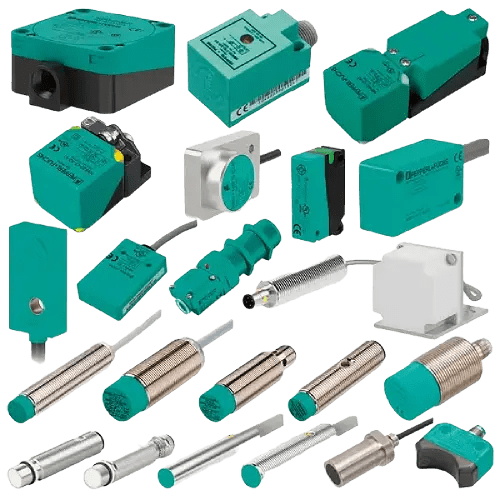

Pepperl+Fuchs NBB Cylindrical sensors

Pepperl Fuchs NBB0

- Detects metal objects at a distance of 0.2 mm to 100 mm.

- Operate in the temperature range from -40 °C to 70 °C.

- Voltage range: 12 V to 24 V.

- Consume current from 1 mA to 20 mA.

- Protection class IP67

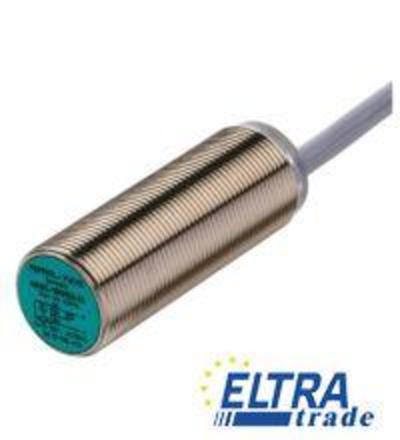

NBB10 industrial inductive sensors

- Distance measurement accuracy up to 0.5 mm

- They operate in the temperature range from -40 to +85 °C.

- They are installed by flush mounting.

- Protected against water and dust.

- International standards for use in explosive atmospheres.

Inductive sensors of the NBB15 series

- Available in a wide range of specifications

- Highly reliable and durable

- Integration with Industry 4.0, wireless communication.

- Sensitivity: from 2 to 100 mm

- Working distance range: wide

- Resistance to contamination: high

- Easy installation and maintenance: high

nbb4

- Explosion protection class: Ex ia, Ex d

- Protection class against dust and moisture: IP68 / IP69K

- Wide range of performance characteristics

- Ability to operate in hazardous areas

Pepperl+Fuchs NBB5

- Provide high switching accuracy

- Designed for operation in harsh environments

- Available in a wide range of operating distances

- Have a high level of protection against dust and moisture

Inductive proximity sensor

- Wide detection range: 0-1.5 mm

- PNP NO + NC output: enables easy integration into industrial systems

Inductive sensor

- Non-contact operation

- High sensitivity

- Wide operating range

- Robust housing

- Linear working range of 8 mm.

- Sensitivity > 90%.

- Housing with IP67 protection class.

- art. 304615-0084

- Non-contact operation

- High sensitivity

- Wide operating range

- Rugged housing

- Linear working range of 2mm.

- Sensitivity of >90% which means.

- It has an IP67-rated housing.

Inductive sensor

- Non-contact operation

- High sensitivity

- Wide operating range

- Robust housing

- Linear working range of 12 mm

- Sensitivity > 90 %

- IP67-rated housing

Industrial inductive sensors Pepperl Fuchs NBB8

- Long operating range

- High sensitivity

- High resistance to contamination

- High resistance to shock and vibration

Inductive sensor NBB8

- Non-contact operation

- High sensitivity

- Wide operating range

- Durable housing

- Linear working range of 30 mm

- Sensitivity > 90 %

- Housing with IP67 protection class

Inductive sensor NBB8

- Increased working distance

- Extended temperature range

- Extended operating voltage range

- Functional safety

- Robust construction

- 4 mm flush

- Increased operating distance

- Extended temperature range

-40 ... +85 ?°C

Series: Cylindrical type, Housing diameter: 3 mm, Housing material: Stainless steel 1.4305 / AISI 303, Rated operating distance: 0.6 mm, Connection type: cable PVC , 2 m, Output type: 3-wire, Installation: embeddable, Type of voltage: DC

Series: Cylindrical type, Housing diameter: 4 mm, Housing material: Stainless steel 1.4305 / AISI 303, Rated operating distance: 0.6 mm, Connection type: cable PUR , 2 m, Output type: 3-wire, Installation: flush, Type of voltage: DC

Pepprel+Fuchs NBB Cylindrical Sensors

Pepperl+Fuchs is a renowned manufacturer of industrial sensors and automation products. The NBB series includes cylindrical inductive sensors that are commonly used in industry to detect metal objects without external contact. Below, we will take a closer look at Pepperl+Fuchs NBB cylindrical sensors.

Understanding NBB Cylindrical Sensors

Cylindrical inductive sensors NBB from Pepperl+Fuchs are an exciting technology that simplifies metal detection in industrial environments. Its reliable non-contact operation, adjustable actuation range, and rugged design make it a valuable tool for improving automation processes. Whether you work in manufacturing, robotics, or any other industry that requires accurate metal detection, this sensor may be the solution you've been looking for.

NBB sensors work by generating an electromagnetic field around their active surface. When a metal object enters this field, it causes a change in its properties. The sensor's internal circuitry detects this change and triggers a response - this could be anything from turning on a conveyor belt to stopping a robotic arm and much more.

Technical Specifications and Features

Let's look at the technical specifications and features that Pepperl Fuchs inductive sensors offer us.

Inductive sensing principle

Cylindrical inductive sensors operate on the principle of electromagnetic induction. They generate an electromagnetic field, and changes in this field caused by the presence of a metallic object are used to detect the object.

Non-contact sensing

These sensors provide non-contact detection, making them suitable for applications where physical contact is problematic or rapid and reliable sensing is required.

Metal object detection

Pepperl+Fuchs NBB cylindrical inductive sensors are designed to detect the presence or absence of metal objects within their sensing range. They are often used in proximity sensing applications.

Robust construction

The NBB series, are typically designed with a robust construction to withstand harsh industrial environments. This may include resistance to vibration, shock, and exposure to various chemicals.

Variety of sizes and configurations

Pepperl+Fuchs offers cylindrical inductive sensors in various sizes and configurations to meet different application requirements. This includes options for different sensing distances and diameters.

Adjustable sensing range

Some models may feature adjustable sensing ranges, allowing for flexibility in adapting the sensor to specific application needs.

Output options

Cylindrical inductive sensors provide digital output signals, indicating the presence or absence of the detected object. Output options may include NPN or PNP configurations.

LED indication

NBB sensors come equipped with LED indicators to provide visual feedback on the sensor's operational status, making it easier for operators to diagnose and troubleshoot.

Protection ratings

Pepperl+Fuchs NBB sensors have specific protection ratings of IP67 that indicate their resistance to dust and water, which is crucial for applications in harsh or outdoor environments.

This line of proximity sensors has cylindrical type of enclosure and diameter from 3 to 40 mm with different types of cuts.

The primary features of cylindrical inductive sensors:

- assured reaction zone 0-20 and 25 mm;

- 3-4 wire connection;

- switching frequency: 25, 20, 100, 500, 400, 800, 700, 1500, 3000, 2000, 5000 Hz;

- output types: PNP, NAMUR (DIN 19234), NPN, output (analog) 0-20 mA (sensors of IA series), Interface AS;

- voltage: 660, 1060, 1060 DC, 20253 AC;

- degree protection: IP 67 and IP68/IP69K;

- operating temperature range: -25...+70°С, there are models of sensors with extended temperature ranges: 0...+200°С , -25...+100°С, -40...+150°С.

Choosing the Right NBB Sensor for Your Industry

Choosing the right NBB sensor for your industry involves considering several key factors to ensure that the sensor meets the specific requirements of your application. It's essential to refer to the product documentation and technical specifications provided by Pepperl+Fuchs for accurate and detailed information. Here are some factors to consider when choosing from NBB cylindrical sensor variants.

Application requirements

Clearly define the requirements of your application. Consider factors such as the type of metal to be detected, the required sensing distance, and the environmental conditions in which the sensor will operate.

Type of metal detection

Different NBB sensors may be optimized for specific metal types. Ensure that the sensor you choose is suitable for detecting the type of metal relevant to your application.

Sensing distance

The sensing distance is a crucial specification. Choose a sensor with a sensing range that accommodates the distance at which you need to detect metal objects in your application.

Diameter and form factor

Consider the size and form factor of the sensor. Choose a diameter that fits your installation requirements and provides the necessary coverage for the application.

Environmental conditions

Assess the environmental conditions in which the sensor will operate. Consider factors such as temperature, humidity, and exposure to dust or liquids. Ensure that the sensor has the appropriate protection ratings (e.g., IP67) for your environment.

Output configuration

Determine whether your control system requires an NPN or PNP output configuration. Choose a sensor with the appropriate output to integrate with your existing equipment seamlessly.

Voltage and current ratings

Ensure that the sensor's voltage and current ratings are compatible with your power supply and electrical system.

Adjustability and flexibility

Some sensors offer adjustable sensing ranges. If your application requires flexibility in the detection range, consider sensors that allow for adjustments.

Installation and mounting options

Evaluate the installation requirements and mounting options. Choose a sensor that can be easily integrated into your machinery or process.

Certifications and compliance

Verify that the sensor complies with relevant industry standards and regulations. Look for certifications such as CE, UL, or others applicable to your industry.

Reliability and durability

Consider the reliability and durability of the sensor. Choose a sensor that is robust enough to withstand the conditions and demands of your industry.

Cost considerations

Evaluate the overall cost of the sensor, including its purchase price, installation costs, and potential long-term maintenance expenses.