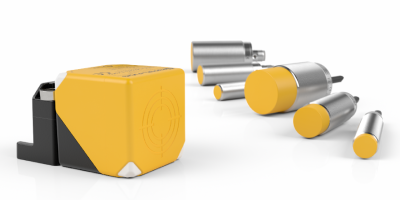

Pepperl+Fuchs NCB - NCN Cylindrical sensors

NCB5 inductive sensors

- Flexible end piece

- Metal end element

- Extended sensing area

- High sensitivity

NCB15 inductive sensors

- Anti-Rattle

- Differential measurement

- Pulse measurement

- Distance measurement

- Different types of outputs

- Different sizes and shapes

NCB4 inductive sensors

- A wide range of options

- Protection against environmental influences

- Can be used in industrial Internet of Things (IIoT) systems

- High accuracy

Pepperl Fuchs NCB8 sensors

- Inductive sensors

- High accuracy and reliability

- Wide range of functions and options

- Ease of use

- Competitive price

- Series: Cylindrical type,

- Housing diameter: 12 mm, Housing material: Stainless steel 1.4305 / AISI 303,

- Rated operating distance: 4 mm,

- Connection type: Connector M12 x 1 , 4-pin,

- Output type: 2-wire,

- Installation: non-flush, Type of voltage: DC

Inductive sensor NCB1.5

- Non-contact detection of metal objects

- Reliability and durability

- High sensitivity

- Easy installation and operation

- Protection class: IP67

- Operating frequency: 100 kHz

- Temperature range: -25 to 70 degrees Celsius

- Mounting: on a DIN rail

Series: Cylindrical type, Housing diameter: 18 mm, Housing material: Stainless steel 1.4305 / AISI 303, Rated operating distance: 5 mm, Connection type: cable PUR , 2 m, Output type: 2-wire, Installation: embeddable, Type of voltage: DC

ncn3:

- The principle of changing the inductance of the coil is used

- Wide range of working distances from 1 mm to 1000 mm.

- Work in a wide temperature range

- Different types of detection zones

- Different types of output signal

NCN4 sensors

- NCN4 sensors are designed using advanced technologies and materials

- The sensors can be used in various conditions

- Can detect metal objects even of small size

- Provide high accuracy of object detection

ncn8

- Sensitivity: 5 to 100 mA

- Accuracy: ±0.5 to ±1.0 mm

- Repetition rate: 1 to 100 Hz

- Viewing angle: 10 to 180 degrees

- Mounting height: 5 to 50 mm

- 1.5 mm flush

- 0...1.21mm

- 2 sons

Inductive sensor

No unusable area

5 mm flush

Use of standard metallic actuating surfaces

Series: Cylindrical type, Housing diameter: 18 mm, Housing material: Stainless steel 1.4305 / AISI 303, Rated operating distance: 1.5 mm, Connection type: cable PVC , 2 m, Output type: 3-wire, Installation: flush, Type of voltage: DC

Series: Cylindrical type, Housing diameter: 18 mm, Housing material: Stainless steel 1.4305 / AISI 303, Rated operating distance: 5 mm, Connection type: Connector M12 x 1 , 4-pin, Output type: 2-wire, Installation: flush, Type of voltage: DC

In modern machine tools and high-precision equipment, where it is important to control the position of structural elements, inductive cylindrical sensors are installed. We will look at in this article what Pepperl+Fuchs NCB - NCN cylindrical sensors are used for and how they work.

Features and Benefits of NCB - NCN Cylindrical Sensors

Inductive sensors are equipment with a non-contact principle of operation, i.e., the sensor does not require physical contact with the object to operate. This means no mechanical wear, which has a significant impact on the life of the components and eliminates the need for their maintenance. By virtue of the principle of operation, inductive sensors are used in cases where it is required to detect a metal object or an object made of magnetic/ferromagnetic materials. Non-metallic objects are ignored by the sensor.

An inductive sensor consists of several main components:

- a metal (most often brass or steel) or plastic case in which all sensor components are placed;

- an oscillatory circuit coil located directly behind a plastic or metal so-called sensitive surface of the sensor;

- a generator that creates an electromagnetic field;

- Schmitt trigger, which converts an analog signal into a discrete logic;

- an amplifier that provides a sufficient level of the output signal for its further transmission;

- one or more LED indicators - most often to indicate operation, but in some cases also indicating the presence of sensor power and configuration status;

- a compound that fills the entire internal space of the sensor to protect electronic components from moisture and small particles;

- cable, terminal box, or connector for connecting the sensor.

The principle of operation of an inductive sensor is based on a change in the inductance of the coil and core - that is why the sensor is called inductive. It comes down to a few basic steps:

- the sensor is powered

- the generator generates a magnetic field in the area of the coil

- when a metal, magnetic or ferromagnetic object enters the sensor area, eddy currents are induced in it, changing the amplitude of the generator oscillations

- amplitude change provides an analog signal output

- Schmitt trigger converts an analog signal into a discrete logic

- the amplifier increases the signal level to the required value

Like any other electronic device, an inductive sensor has a number of primary and secondary parameters. The former are the main ones in selecting a sensor for a specific task, while the latter allows you to determine the suitability of the sensor for use in specific conditions.

The main advantages of Pepperl+Fuchs cylindrical sensors are.

- Quite a small distance to the object: up to 80 mm.

- Relatively low price.

- Long service life.

- Resistance to adverse environmental conditions.

- High measurement speed.

Types and Specifications of NCB - NCN Cylindrical Sensors

Pepperl+Fuchs NCN and NCB cylindrical sensors are inductive proximity sensors based on the principle of electromagnetic induction. They generate a high-frequency electromagnetic field and detect changes in the area caused by metallic objects within their detection range. The inductive sensor is designed to control the movement of the working body without direct contact with it. Its main scope is machine tools, precision medical devices, automation systems for technological processes, measurement, and control of the shape of the product.

In practice, a considerable variety of inductive sensors can be divided into two large categories, depending on the current supply type - AC and DC. Depending on the state of the contacts, inductive sensors are:

- closing - when the controlled object is moved, it is switched to the on position;

- opening - in case of impact, the inductive sensor switches the contacts to the off position;

- switching - simultaneously combines both previous options. For one switching, it puts one output on, the second in the off position.

According to the method of data transmission, inductive sensors are divided into analog, electronic, and digital. In the first case, identical coils and ferromagnetic cores are used. Electronic ones use a Schmidt trigger instead of ferromagnets to obtain a hysteresis component. Digital ones are made in the format of printed circuit boards on microcircuits. In addition, the types are subdivided according to the number of sensor leads: two, three, four, or five.

According to the number of measuring circuits, inductive sensors are divided into single and differential. The first of them has one coil and one measurement circuit. The second type implies two sensors, the measuring circuits included in the antiphase to compare readings.

Installation and Maintenance of NCB - NCN Cylindrical Sensors

Here are tips for the installation and maintenance of Pepperl+Fuchs NCB - NCN.

- Select the appropriate type of NCB or NCN cylindrical probe depending on your application requirements.

- Install the sensor in a place where it can effectively detect a metal target.

- Keep the sensor away from other metal objects or sources of electromagnetic interference, as they may interfere with its operation.

- Use suitable mounting hardware.

- Align the sensitive surface of the sensor perpendicular to the target surface.

- Follow the wiring diagram given in the technical description of the sensor.

- Ground the sensor correctly.

- Perform functional testing after installation.

- Perform routine inspections of the sensor.

- Clean the sensor regularly.

- Periodically check the sensitivity range of the sensor.

- Check wiring connections between the sensor and control system.

- Make sure the sensor is suitable for the operating environment in terms of temperature, humidity, and exposure to chemicals or aggressive substances.